eWORK 2000 - European Telework Week

eWORK 2000 - European Telework Week

eWORK 2000 - European Telework Week

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

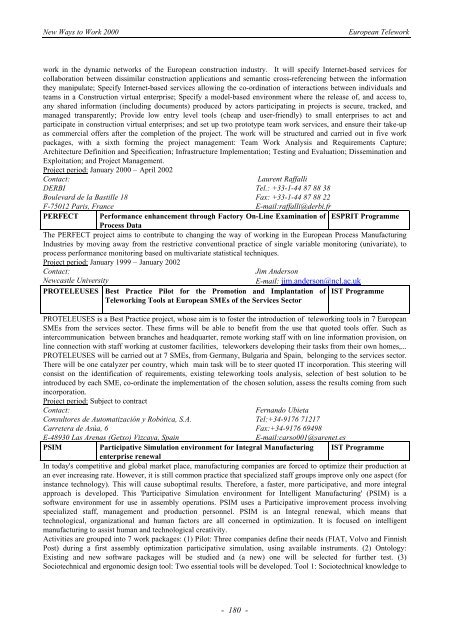

New Ways to Work <strong>2000</strong><strong>European</strong> <strong>Telework</strong>work in the dynamic networks of the <strong>European</strong> construction industry. It will specify Internet-based services forcollaboration between dissimilar construction applications and semantic cross-referencing between the informationthey manipulate; Specify Internet-based services allowing the co-ordination of interactions between individuals andteams in a Construction virtual enterprise; Specify a model-based environment where the release of, and access to,any shared information (including documents) produced by actors participating in projects is secure, tracked, andmanaged transparently; Provide low entry level tools (cheap and user-friendly) to small enterprises to act andparticipate in construction virtual enterprises; and set up two prototype team work services, and ensure their take-upas commercial offers after the completion of the project. The work will be structured and carried out in five workpackages, with a sixth forming the project management: Team Work Analysis and Requirements Capture;Architecture Definition and Specification; Infrastructure Implementation; Testing and Evaluation; Dissemination andExploitation; and Project Management.Project period: January <strong>2000</strong> – April 2002Contact:DERBIBoulevard de la Bastille 18F-75012 Paris, FranceLaurent RaffalliTel.: +33-1-44 87 88 38Fax: +33-1-44 87 88 22E-mail:raffalli@derbi.frESPRIT ProgrammePERFECT Performance enhancement through Factory On-Line Examination ofProcess DataThe PERFECT project aims to contribute to changing the way of working in the <strong>European</strong> Process ManufacturingIndustries by moving away from the restrictive conventional practice of single variable monitoring (univariate), toprocess performance monitoring based on multivariate statistical techniques.Project period: January 1999 – January 2002Contact:Newcastle UniversityPROTELEUSESJim AndersonE-mail: jim.anderson@ncl.ac.ukIST ProgrammeBest Practice Pilot for the Promotion and Implantation of<strong>Telework</strong>ing Tools at <strong>European</strong> SMEs of the Services SectorPROTELEUSES is a Best Practice project, whose aim is to foster the introduction of teleworking tools in 7 <strong>European</strong>SMEs from the services sector. These firms will be able to benefit from the use that quoted tools offer. Such asintercommunication between branches and headquarter, remote working staff with on line information provision, online connection with staff working at customer facilities, teleworkers developing their tasks from their own homes,...PROTELEUSES will be carried out at 7 SMEs, from Germany, Bulgaria and Spain, belonging to the services sector.There will be one catalyzer per country, which main task will be to steer quoted IT incorporation. This steering willconsist on the identification of requirements, existing teleworking tools analysis, selection of best solution to beintroduced by each SME, co-ordinate the implementation of the chosen solution, assess the results coming from suchincorporation.Project period: Subject to contractContact:Consultores de Automatización y Robótica, S.A.Carretera de Asúa, 6E-48930 Las Arenas (Getxo) Vizcaya, SpainFernando UbietaTel:+34-9176 71217Fax:+34-9176 69498E-mail:carso001@sarenet.esIST ProgrammePSIM Participative Simulation environment for Integral Manufacturingenterprise renewalIn today's competitive and global market place, manufacturing companies are forced to optimize their production atan ever increasing rate. However, it is still common practice that specialized staff groups improve only one aspect (forinstance technology). This will cause suboptimal results. Therefore, a faster, more participative, and more integralapproach is developed. This 'Participative Simulation environment for Intelligent Manufacturing' (PSIM) is asoftware environment for use in assembly operations. PSIM uses a Participative improvement process involvingspecialized staff, management and production personnel. PSIM is an Integral renewal, which means thattechnological, organizational and human factors are all concerned in optimization. It is focused on intelligentmanufacturing to assist human and technological creativity.Activities are grouped into 7 work packages: (1) Pilot: Three companies define their needs (FIAT, Volvo and FinnishPost) during a first assembly optimization participative simulation, using available instruments. (2) Ontology:Existing and new software packages will be studied and (a new) one will be selected for further test. (3)Sociotechnical and ergonomic design tool: Two essential tools will be developed. Tool 1: Sociotechnical knowledge to- 180 -