chemkor schedule 80 fittings - Fabco Plastics Wholesale Limited

chemkor schedule 80 fittings - Fabco Plastics Wholesale Limited

chemkor schedule 80 fittings - Fabco Plastics Wholesale Limited

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

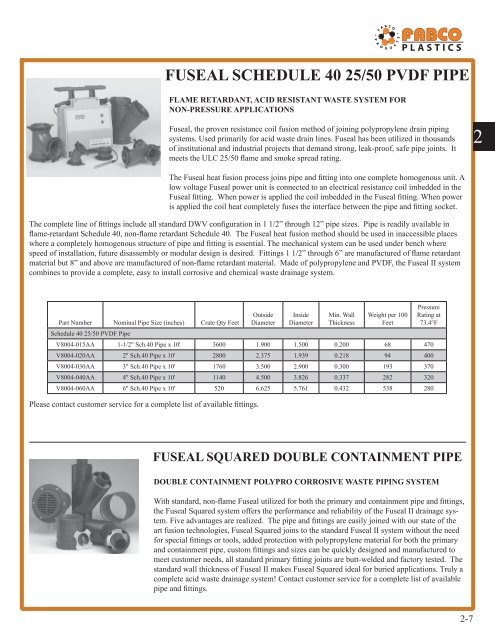

FUSEAL SCHEDULE 40 25/50 PVDF PIPE<br />

FLAME RETARDANT, ACID RESISTANT WASTE SYSTEM FOR<br />

NON-PRESSURE APPLICATIONS<br />

Fuseal, the proven resistance coil fusion method of joining polypropylene drain piping<br />

systems. Used primarily for acid waste drain lines. Fuseal has been utilized in thousands<br />

of institutional and industrial projects that demand strong, leak-proof, safe pipe joints. It<br />

meets the ULC 25/50 fl ame and smoke spread rating.<br />

The Fuseal heat fusion process joins pipe and fi tting into one complete homogenous unit. A<br />

low voltage Fuseal power unit is connected to an electrical resistance coil imbedded in the<br />

Fuseal fi tting. When power is applied the coil imbedded in the Fuseal fi tting. When power<br />

is applied the coil heat completely fuses the interface between the pipe and fi tting socket.<br />

The complete line of fi ttings include all standard DWV confi guration in 1 1/2” through 12” pipe sizes. Pipe is readily available in<br />

fl ame-retardant Schedule 40, non-fl ame retardant Schedule 40. The Fuseal heat fusion method should be used in inaccessible places<br />

where a completely homogenous structure of pipe and fi tting is essential. The mechanical system can be used under bench where<br />

speed of installation, future disassembly or modular design is desired. Fittings 1 1/2” through 6” are manufactured of fl ame retardant<br />

material but 8” and above are manufactured of non-fl ame retardant material. Made of polypropylene and PVDF, the Fuseal II system<br />

combines to provide a complete, easy to install corrosive and chemical waste drainage system.<br />

Outside Inside Min. Wall Weight per 100<br />

Pressure<br />

Rating at<br />

Part Number Nominal Pipe Size (inches) Crate Qty Feet Diameter Diameter Thickness Feet 73.4°F<br />

Schedule 40 25/50 PVDF Pipe<br />

V<strong>80</strong>04-015AA 1-1/2" Sch.40 Pipe x 10' 3600 1.900 1.500 0.200 68 470<br />

V<strong>80</strong>04-020AA 2" Sch.40 Pipe x 10' 2<strong>80</strong>0 2.375 1.939 0.218 94 400<br />

V<strong>80</strong>04-030AA 3" Sch.40 Pipe x 10' 1760 3.500 2.900 0.300 193 370<br />

V<strong>80</strong>04-040AA 4" Sch.40 Pipe x 10' 1140 4.500 3.826 0.337 282 320<br />

V<strong>80</strong>04-060AA 6" Sch.40 Pipe x 10' 520 6.625 5.761 0.432 538 2<strong>80</strong><br />

Please contact customer service for a complete list of available fi ttings.<br />

FUSEAL SQUARED DOUBLE CONTAINMENT PIPE<br />

DOUBLE CONTAINMENT POLYPRO CORROSIVE WASTE PIPING SYSTEM<br />

With standard, non-fl ame Fuseal utilized for both the primary and containment pipe and fi ttings,<br />

the Fuseal Squared system offers the performance and reliability of the Fuseal II drainage system.<br />

Five advantages are realized. The pipe and fi ttings are easily joined with our state of the<br />

art fusion technologies, Fuseal Squared joins to the standard Fuseal II system without the need<br />

for special fi ttings or tools, added protection with polypropylene material for both the primary<br />

and containment pipe, custom fi ttings and sizes can be quickly designed and manufactured to<br />

meet customer needs, all standard primary fi tting joints are butt-welded and factory tested. The<br />

standard wall thickness of Fuseal II makes Fuseal Squared ideal for buried applications. Truly a<br />

complete acid waste drainage system! Contact customer service for a complete list of available<br />

pipe and fi ttings.<br />

2-7<br />

2