chemkor schedule 80 fittings - Fabco Plastics Wholesale Limited

chemkor schedule 80 fittings - Fabco Plastics Wholesale Limited

chemkor schedule 80 fittings - Fabco Plastics Wholesale Limited

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Desirable Properties<br />

Global Poly Systems PE3408 polyethylene piping system<br />

provides many desirable properties for piping:<br />

• Heat fusion joining for strong, lifetime leak free joints<br />

• Flexibility, fatigue resistance, toughness, light weight and<br />

impact resistance for easy, low cost installation<br />

• Resistance to environmental stress cracking<br />

• Resistant to surges and durable performance under<br />

temperature extremes<br />

• High strength and stiffness to withstand internal pressure and<br />

external loads<br />

• Corrosion and Chemical resistant<br />

• Hazen Williams C Factor is 150 and doesn’t change over<br />

time<br />

Global pipe meets or exceeds these standards:<br />

NSF 14 and 61<br />

NSF “c”<br />

ASTM F-714 Polyethylene Plastic Pipe (SDR-PR) based<br />

on outside diameter<br />

ASTM D1248 PE3408 materials<br />

ASTM D-3350 PE345465C Cell classification (black)<br />

Materials<br />

Material used for the manufacturing of polyethylene pipe shall<br />

be PE3408 High Density Polyethylene (HDPE) prime resin<br />

as listed with the Plastic Pipe Institute (PPI). It complies with<br />

ASTM D1248 as a Type 111, Class C, Category 5, Grade P34<br />

and with ASTM D3350 as a 345465C cell class material. In<br />

addition, materials used for the manufacture of the HDPE pipe<br />

shall meet the following physical property requirements.<br />

HDPE PIPE<br />

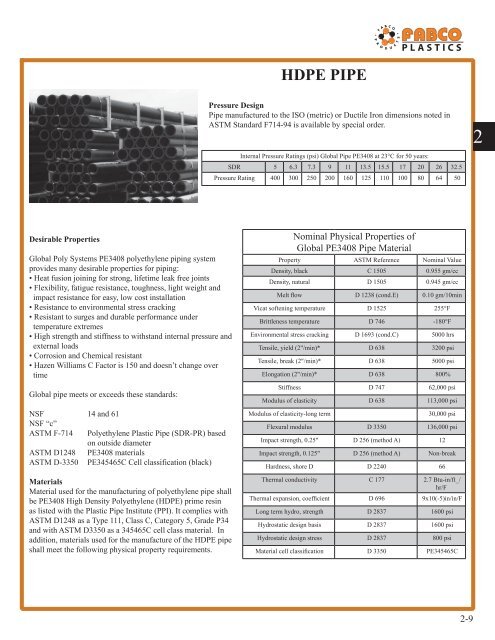

Pressure Design<br />

Pipe manufactured to the ISO (metric) or Ductile Iron dimensions noted in<br />

ASTM Standard F714-94 is available by special order.<br />

Internal Pressure Ratings (psi) Global Pipe PE3408 at 23°C for 50 years:<br />

SDR 5 6.3 7.3 9 11 13.5 15.5 17 20 26 32.5<br />

Pressure Rating 400 300 250 200 160 125 110 100 <strong>80</strong> 64 50<br />

Nominal Physical Properties of<br />

Global PE3408 Pipe Material<br />

Property ASTM Reference Nominal Value<br />

Density, black C 1505 0.955 gm/cc<br />

Density, natural D 1505 0.945 gm/cc<br />

Melt fl ow D 1238 (cond.E) 0.10 gm/10min<br />

Vicat softening temperature D 1525 255°F<br />

Brittleness temperature D 746 -1<strong>80</strong>°F<br />

Environmental stress cracking D 1693 (cond.C) 5000 hrs<br />

Tensile, yield (2"/min)* D 638 3200 psi<br />

Tensile, break (2"/min)* D 638 5000 psi<br />

Elongation (2"/min)* D 638 <strong>80</strong>0%<br />

Stiffness D 747 62,000 psi<br />

Modulus of elasticity D 638 113,000 psi<br />

Modulus of elasticity-long term 30,000 psi<br />

Flexural modulus D 3350 136,000 psi<br />

Impact strength, 0.25" D 256 (method A) 12<br />

Impact strength, 0.125" D 256 (method A) Non-break<br />

Hardness, shore D D 2240 66<br />

Thermal conductivity C 177 2.7 Btu-in/ft_/<br />

hr/F<br />

Thermal expansion, coeffi cient D 696 9x10(-5)in/in/F<br />

Long term hydro, strength D 2837 1600 psi<br />

Hydrostatic design basis D 2837 1600 psi<br />

Hydrostatic design stress D 2837 <strong>80</strong>0 psi<br />

Material cell classifi cation D 3350 PE345465C<br />

2-9<br />

2