- Page 2 and 3:

KEMENTERIAN PERINDUSTRIAN BALAI BES

- Page 4 and 5:

PEDOMAN PEMETAAN TEKNOLOGI DI INDUS

- Page 6 and 7:

RINGKASAN EKSEKUTIF Perkembangan pe

- Page 8 and 9:

delignifikasi berlanjut (extended d

- Page 10 and 11:

potensi untuk dimanfaatkan. Atas da

- Page 12 and 13:

3.4. Optimasi kinerja Chemical Reco

- Page 14 and 15:

DAFTAR GAMBAR Gambar 1.1. Prediksi

- Page 16 and 17:

Tabel 3.1 Konservasi energi pada pe

- Page 18 and 19:

umi naik 0,5 o C, angka ini akan na

- Page 20 and 21:

kertas, industri tekstil, indusri k

- Page 22 and 23:

Gambar 1.1 Prediksi Emisi GRK di In

- Page 24 and 25:

tahun 2009, perusahaan industri pul

- Page 26 and 27:

pulp dan kertas dibandingkan dengan

- Page 28 and 29:

Tabel 1.8 Rincian Besaran Emisi Kar

- Page 30 and 31:

Pada pembuatan pulp mekanis lignin

- Page 32 and 33:

Gambar 2.1 Diagram Proses Pabrik Pu

- Page 34 and 35:

(misalnya, dissolving, non-kayu). P

- Page 36 and 37:

meningkatkan kandungan padatannya m

- Page 38 and 39:

Kondensat Recovery boiler Panas sek

- Page 40 and 41:

dari proses pemulihan kembali bahan

- Page 42 and 43:

Gambar 2.5 Distribusi Konsumsi Ener

- Page 44 and 45:

2.3.1 Pengelolaan Limbah cair Ditin

- Page 46 and 47:

Teknologi pengelolaan melalui peman

- Page 48 and 49:

BAB III TEKNOLOGI PROSES PULPING HE

- Page 50 and 51:

Tabel 3.1 Konservasi energi pada pe

- Page 52 and 53:

Gambar 3.2 Dimensi tumpukan serpih

- Page 54 and 55:

Gambar 3.4 Ringkasan berbagai siklu

- Page 56 and 57:

yang selanjutnya disimpan dalam hot

- Page 58 and 59:

Gambar 3.6 Digester kontinyu dengan

- Page 60 and 61:

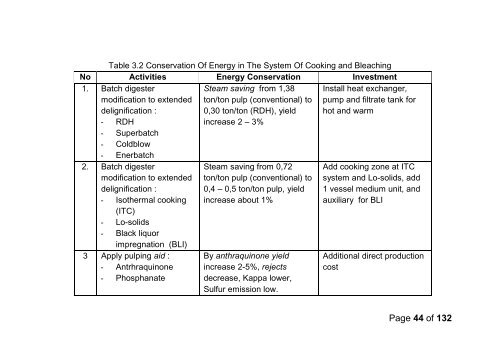

Ringkasan konservasi energi pada pa

- Page 62 and 63:

wash master. Dilution factor sekita

- Page 64 and 65:

Tabel 3.4 Konservasi energi pada si

- Page 66 and 67:

3.5 Optimasi kinerja Power Boiler b

- Page 68 and 69:

Tabel 3.5.Konservasi energi pada si

- Page 70 and 71:

Konservasi energi lain yang dapat d

- Page 72 and 73:

4.1.2 Mesin Kertas : Bagian Pembent

- Page 74 and 75:

ditingkatkan dari 15 % menjadi 60 -

- Page 76 and 77:

Tabel 4.1 Perbandingan Kinerja Tekn

- Page 78 and 79:

Tabel 4.2 Peluang Penghematan Energ

- Page 80 and 81:

Tabel 4.4 Sumber Emisi Karbon pada

- Page 82 and 83:

BAB V PENGELOLAAN LINGKUNGAN PADA I

- Page 84 and 85:

diutamakan untuk mengolah air limba

- Page 86 and 87:

Untuk mengoptimalkan dan mendistrib

- Page 88 and 89:

5.1.2 Pengembangan Teknologi Anaero

- Page 90 and 91:

merupakan sumber karbon yang berkon

- Page 92 and 93:

Gambar 5.1 Fase-Fase Pada Tahapan P

- Page 94 and 95:

memasang peralatan seperti turbin,

- Page 96 and 97:

5.2.2.1.a. Rotary Kiln Incinerator

- Page 98 and 99:

Di Indonesia, penerapan insinerator

- Page 100 and 101:

mikroba termofilik. Pada suhu di at

- Page 102 and 103:

5.2.3.1.b. Proses pengomposon siste

- Page 104 and 105:

zat organik telah dipertimbangkan s

- Page 106 and 107:

Gambar 5.8 Digestasi Anaerobik Satu

- Page 108 and 109:

meningkatkan produktivitas berbagai

- Page 110 and 111:

menyebabkan terjadinya pencemaran u

- Page 112 and 113:

Gambar 5.10. (A). Cyclone dan Multi

- Page 114 and 115:

Gambar 5.12. Electrostatic Precipit

- Page 116 and 117:

disemprotkan dan mengalir ke bawah

- Page 118 and 119:

Counter Current Packed Tower Bubble

- Page 120 and 121:

Metode FGD Metode Kering Absorben R

- Page 122 and 123:

NOx yang terbentuk sebagai hasil pe

- Page 124 and 125:

Metoda Non selective catalytic redu

- Page 126 and 127:

BAB VI PENUTUP Indonesia ikut berpe

- Page 128 and 129:

Teknologi pengelolaan lingkungan me

- Page 130 and 131:

Gavrilescu, D. 2008. “Energy from

- Page 132 and 133:

Stultz, S.C., and J.B. Kitto., 2000

- Page 134 and 135:

No Company Name APPENDIX 1 DISTRIBU

- Page 136 and 137:

LANJUTAN No Company Name Mill Site

- Page 138 and 139:

LANJUTAN No Company Name Mill Site

- Page 140 and 141:

APPENDIX 2 PAPER CONSUMPTION IN VAR

- Page 142 and 143:

APPENDIX 2 (continuation) Country C

- Page 144 and 145:

Coated wood-free paper - integrated

- Page 146 and 147:

APPENDIX 4 ENERGY CONSUMPTION FOR U

- Page 149 and 150:

MINISTRY OF INDUSTRY CENTER FOR PUL

- Page 151 and 152:

TECHNOLOGY MAPPING GUIDELINE FOR PU

- Page 153 and 154:

EXECUTIVE SUMMARY The development o

- Page 155 and 156: pulp bleaching done by adding a hea

- Page 157 and 158: device SOx and NOx and also control

- Page 159 and 160: 3.3 Application Washing Technologie

- Page 161 and 162: Figure 3.7 Black Liquor Impregnatio

- Page 163 and 164: Table 3.5 Conservation Of Energy In

- Page 165 and 166: 15% CH4, CFCs by 12% and 4% N2O, an

- Page 167 and 168: governments and stakeholders as a b

- Page 169 and 170: Figure 1.1 Forecast of GHG Emission

- Page 171 and 172: paper industry in Indonesia are 81

- Page 173 and 174: Table 1.5 Specific Energy Consumpti

- Page 175 and 176: Table 1.8 Details of Carbon Emissio

- Page 177 and 178: have a good opacity, and easy to ab

- Page 179 and 180: Figure 2.1 Process Diagram of Kraft

- Page 181 and 182: Kraft pulping process using alkalin

- Page 183 and 184: urned, and Na2SO4 reduced to Na2S.

- Page 185 and 186: Kondensat Recovery boiler Secondary

- Page 187 and 188: Pulp mills in Indonesia fulfill the

- Page 189 and 190: The main energy source used in the

- Page 191 and 192: alkaline pH, high contamination COD

- Page 193 and 194: will be generated carbon emission s

- Page 195 and 196: CHAPTER III PULPING TECHNOLOGY FOR

- Page 197 and 198: Table 3.1 Conservation Of Energy In

- Page 199 and 200: Figure 3.1 Mechanism of chip damage

- Page 201 and 202: Figure 3.3 Cycle Of Displacement Ba

- Page 203 and 204: Figure 3.5 System RDH equipment / S

- Page 205: With a uniform temperature througho

- Page 209 and 210: 3.3 Application Washing Technologie

- Page 211 and 212: Udara kuaterner Udara sekunder ting

- Page 213 and 214: sootblowing intelligent sootblowing

- Page 215 and 216: Figure 3.11 FBC and CFBC Page 52 of

- Page 217 and 218: Other energy conservation can be do

- Page 219 and 220: process of separating water from th

- Page 221 and 222: facilities. For the hood that uses

- Page 223 and 224: 4.2 Saving Energy and Carbon Emissi

- Page 225 and 226: Table 4.3 Best 2009 World Energy In

- Page 227 and 228: Table 4.5 Overview of Investment Fo

- Page 229 and 230: chemistry, and biology process or a

- Page 231 and 232: ii. b. Anaerobic System Anaerobic p

- Page 233 and 234: experience growth to form granular

- Page 235 and 236: Table 5.1. Sources and Types of Sol

- Page 237 and 238: There are several solid waste manag

- Page 239 and 240: technology development is equipped

- Page 241 and 242: esulting energy for steam productio

- Page 243 and 244: With this system, the fluidization

- Page 245 and 246: In the composting process temperatu

- Page 247 and 248: closed system requires an investmen

- Page 249 and 250: generally composed of CH 4 55-70%;

- Page 251 and 252: Figure 5.8 Anaerobic Digestion One

- Page 253 and 254: Figure 5.9 Flowchart of Two Phase A

- Page 255 and 256: Table 5.4 Sources and Characteristi

- Page 257 and 258:

5.3.2.1 Separation of Particulate P

- Page 259 and 260:

). Filter Cloth (Fabric Filter) The

- Page 261 and 262:

time. Separation of pollutants carr

- Page 263 and 264:

Figure 5.14 Packed Tower Scrubber B

- Page 265 and 266:

C. SOx Gas Control SOx gases can be

- Page 267 and 268:

Type of FGD Method Dry Method Absor

- Page 269 and 270:

D. NOx Gas Control NOx emission can

- Page 271 and 272:

Method Selective non catalytic redu

- Page 273 and 274:

incoming gas fan. To avoid the risk

- Page 275 and 276:

Some processes that can save energy

- Page 277 and 278:

REFERENCES Adams, Terry N., 1997,.

- Page 279 and 280:

Industry”, Environmental Energy T

- Page 281 and 282:

_____EPA, 2010. “Available and Em

- Page 283 and 284:

CONTINUE No Company Name Mill Site

- Page 285 and 286:

CONTINUE No Company Name Mill Site

- Page 287 and 288:

CONTINUE No Company Name Mill Site

- Page 289 and 290:

APPENDIX 2 (continuation) Consumpti

- Page 291 and 292:

APPENDIX 3 SPECIFIC ENERGY CONSUMPT

- Page 293 and 294:

Source : all data taken from [249,

- Page 295:

APENDIX 4 GHG EMISSION FROM VARIOUS