Design Challenges: Avoiding the Pitfalls, winning the game - Xilinx

Design Challenges: Avoiding the Pitfalls, winning the game - Xilinx

Design Challenges: Avoiding the Pitfalls, winning the game - Xilinx

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Pblocks can direct <strong>the</strong> flow of <strong>the</strong><br />

design based on <strong>the</strong> connectivity of<br />

different modules. The connectivity<br />

of <strong>the</strong> I/Os to and between modules is<br />

shown for <strong>the</strong> placed and routed<br />

design through net bundles. We create<br />

Pblocks to cover <strong>the</strong> critical paths,<br />

which are usually associated with getting<br />

on or off <strong>the</strong> device.<br />

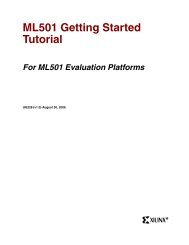

The schematic view also displays<br />

<strong>the</strong> connectivity of <strong>the</strong> design (Figure<br />

2). Pblocks are created ei<strong>the</strong>r in <strong>the</strong><br />

device, schematic, or netlist views.<br />

The critical paths and o<strong>the</strong>r timing<br />

paths relative to <strong>the</strong> existing floorplanning<br />

can be highlighted in <strong>the</strong><br />

device and schematic views.<br />

Normally, <strong>the</strong> schematic view is<br />

used to examine <strong>the</strong> critical modules<br />

and paths without worrying about <strong>the</strong><br />

actual placement of those modules.<br />

The congestion around existing<br />

Pblocks and <strong>the</strong> resource utilization<br />

of a Pblock are seen in <strong>the</strong> device<br />

view. If <strong>the</strong> timing is critical within<br />

<strong>the</strong> Pblock (indicated by a high<br />

resource utilization count) <strong>the</strong>n we<br />

resize <strong>the</strong> Pblock to give <strong>the</strong> congested<br />

logic more room to meet timing by<br />

condensing <strong>the</strong> logic to shorten <strong>the</strong><br />

interconnect lengths and delays. We<br />

can also move <strong>the</strong> Pblocks to alleviate<br />

congestion or merge congested logic<br />

into a single Pblock.<br />

We create and place <strong>the</strong> Pblocks, <strong>the</strong>n<br />

run place and route with our floorplanning<br />

constraints. We also lock <strong>the</strong> locations of <strong>the</strong><br />

larger components and critical logic, which<br />

includes block RAMs, DSP48s, and DCMs.<br />

Then we run place and route on <strong>the</strong> design<br />

and repeat <strong>the</strong> process by reviewing <strong>the</strong> timing<br />

report and placement of <strong>the</strong> design and<br />

modifying <strong>the</strong> constraints (Figure 2). We<br />

can also create smaller “child” Pblocks inside<br />

o<strong>the</strong>r Pblocks to help <strong>the</strong> grouping of a few<br />

components for timing-critical paths.<br />

Place and route is run on individual<br />

Pblocks in addition to <strong>the</strong> entire design.<br />

This helps determine if timing can be met<br />

inside <strong>the</strong> module or Pblock without affecting<br />

<strong>the</strong> rest of <strong>the</strong> design. If we are unable<br />

to meet timing on a specific Pblock, we go<br />

back to <strong>the</strong> source code and re-write it.<br />

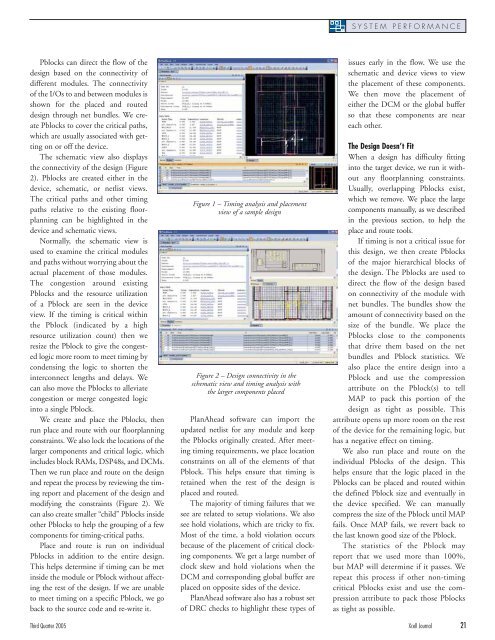

Figure 1 – Timing analysis and placement<br />

view of a sample design<br />

Figure 2 – <strong>Design</strong> connectivity in <strong>the</strong><br />

schematic view and timing analysis with<br />

<strong>the</strong> larger components placed<br />

PlanAhead software can import <strong>the</strong><br />

updated netlist for any module and keep<br />

<strong>the</strong> Pblocks originally created. After meeting<br />

timing requirements, we place location<br />

constraints on all of <strong>the</strong> elements of that<br />

Pblock. This helps ensure that timing is<br />

retained when <strong>the</strong> rest of <strong>the</strong> design is<br />

placed and routed.<br />

The majority of timing failures that we<br />

see are related to setup violations. We also<br />

see hold violations, which are tricky to fix.<br />

Most of <strong>the</strong> time, a hold violation occurs<br />

because of <strong>the</strong> placement of critical clocking<br />

components. We get a large number of<br />

clock skew and hold violations when <strong>the</strong><br />

DCM and corresponding global buffer are<br />

placed on opposite sides of <strong>the</strong> device.<br />

PlanAhead software also has a robust set<br />

of DRC checks to highlight <strong>the</strong>se types of<br />

SYSTEM PERFORMANCE<br />

issues early in <strong>the</strong> flow. We use <strong>the</strong><br />

schematic and device views to view<br />

<strong>the</strong> placement of <strong>the</strong>se components.<br />

We <strong>the</strong>n move <strong>the</strong> placement of<br />

ei<strong>the</strong>r <strong>the</strong> DCM or <strong>the</strong> global buffer<br />

so that <strong>the</strong>se components are near<br />

each o<strong>the</strong>r.<br />

The <strong>Design</strong> Doesn’t Fit<br />

When a design has difficulty fitting<br />

into <strong>the</strong> target device, we run it without<br />

any floorplanning constraints.<br />

Usually, overlapping Pblocks exist,<br />

which we remove. We place <strong>the</strong> large<br />

components manually, as we described<br />

in <strong>the</strong> previous section, to help <strong>the</strong><br />

place and route tools.<br />

If timing is not a critical issue for<br />

this design, we <strong>the</strong>n create Pblocks<br />

of <strong>the</strong> major hierarchical blocks of<br />

<strong>the</strong> design. The Pblocks are used to<br />

direct <strong>the</strong> flow of <strong>the</strong> design based<br />

on connectivity of <strong>the</strong> module with<br />

net bundles. The bundles show <strong>the</strong><br />

amount of connectivity based on <strong>the</strong><br />

size of <strong>the</strong> bundle. We place <strong>the</strong><br />

Pblocks close to <strong>the</strong> components<br />

that drive <strong>the</strong>m based on <strong>the</strong> net<br />

bundles and Pblock statistics. We<br />

also place <strong>the</strong> entire design into a<br />

Pblock and use <strong>the</strong> compression<br />

attribute on <strong>the</strong> Pblock(s) to tell<br />

MAP to pack this portion of <strong>the</strong><br />

design as tight as possible. This<br />

attribute opens up more room on <strong>the</strong> rest<br />

of <strong>the</strong> device for <strong>the</strong> remaining logic, but<br />

has a negative effect on timing.<br />

We also run place and route on <strong>the</strong><br />

individual Pblocks of <strong>the</strong> design. This<br />

helps ensure that <strong>the</strong> logic placed in <strong>the</strong><br />

Pblocks can be placed and routed within<br />

<strong>the</strong> defined Pblock size and eventually in<br />

<strong>the</strong> device specified. We can manually<br />

compress <strong>the</strong> size of <strong>the</strong> Pblock until MAP<br />

fails. Once MAP fails, we revert back to<br />

<strong>the</strong> last known good size of <strong>the</strong> Pblock.<br />

The statistics of <strong>the</strong> Pblock may<br />

report that we used more than 100%,<br />

but MAP will determine if it passes. We<br />

repeat this process if o<strong>the</strong>r non-timing<br />

critical Pblocks exist and use <strong>the</strong> compression<br />

attribute to pack those Pblocks<br />

as tight as possible.<br />

Third Quarter 2005 Xcell Journal 21