Installation & Operation Manual - StellarSupport - John Deere

Installation & Operation Manual - StellarSupport - John Deere

Installation & Operation Manual - StellarSupport - John Deere

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

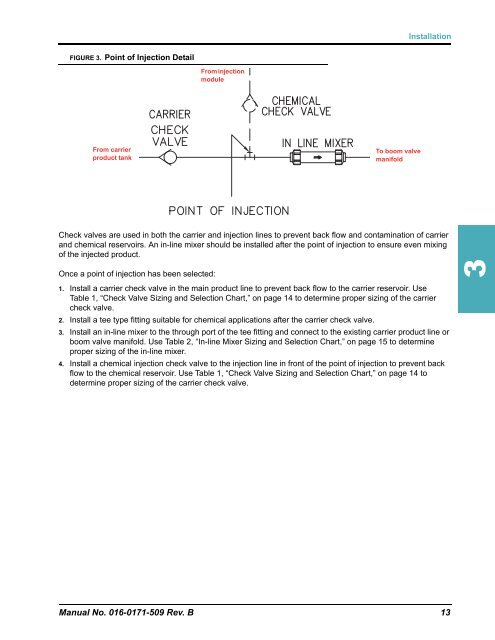

FIGURE 3. Point of Injection Detail<br />

From carrier<br />

product tank<br />

<strong>Installation</strong><br />

Check valves are used in both the carrier and injection lines to prevent back flow and contamination of carrier<br />

and chemical reservoirs. An in-line mixer should be installed after the point of injection to ensure even mixing<br />

of the injected product.<br />

Once a point of injection has been selected:<br />

From injection<br />

module<br />

To boom valve<br />

manifold<br />

1. Install a carrier check valve in the main product line to prevent back flow to the carrier reservoir. Use<br />

Table 1, “Check Valve Sizing and Selection Chart,” on page 14 to determine proper sizing of the carrier<br />

check valve.<br />

2. Install a tee type fitting suitable for chemical applications after the carrier check valve.<br />

3. Install an in-line mixer to the through port of the tee fitting and connect to the existing carrier product line or<br />

boom valve manifold. Use Table 2, “In-line Mixer Sizing and Selection Chart,” on page 15 to determine<br />

proper sizing of the in-line mixer.<br />

4. Install a chemical injection check valve to the injection line in front of the point of injection to prevent back<br />

flow to the chemical reservoir. Use Table 1, “Check Valve Sizing and Selection Chart,” on page 14 to<br />

determine proper sizing of the carrier check valve.<br />

<strong>Manual</strong> No. 016-0171-509 Rev. B 13<br />

3