Download the file. - Groupe SEB

Download the file. - Groupe SEB

Download the file. - Groupe SEB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

E X P E R T I S E<br />

54-55<br />

OUTSOURCING, A TACTICAL LEVER<br />

Today’s industrial model involves a trade-off between own-production and outsourcing.<br />

The Group adapts its response strategically, and uses outsourcing at different levels in <strong>the</strong><br />

production chain. In <strong>the</strong> first place, outsourcing gives access to complex sub-assemblies which<br />

are very labour-intensive, and which would erode its competitive edge if <strong>the</strong> Group made <strong>the</strong>m<br />

in its own factories. In <strong>the</strong> second place, sourcing can give access, if necessary, to finished<br />

products*, especially where this concerns renewal of existing products with no new<br />

innovation, or an urgent need to replenish stocks – or again, if this option is better suited to <strong>the</strong><br />

commercial outlook of <strong>the</strong> product. The decision to outsource involves close collaboration with<br />

suppliers to ensure compliance with <strong>the</strong> Group’s high standards.<br />

O P E R AT I N G S T R U C T U R E S<br />

BRAZIL’S RECIfE PLANT<br />

UPGRADED TO A fULL-SCALE<br />

fACTORY: 1.7 MILLION ARTICLES<br />

PRODUCED IN 2010<br />

* Share of sourcing in 2010: 30%<br />

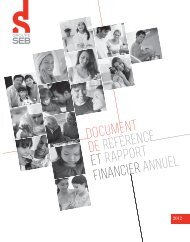

Rumilly: 45 million articles<br />

made in 2010.<br />

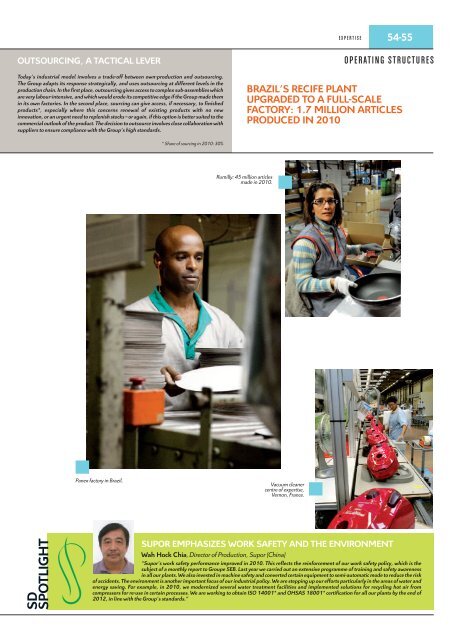

Panex factory in Brazil.<br />

Vacuum cleaner<br />

centre of expertise,<br />

Vernon, France.<br />

SD<br />

SPOTLIGHT<br />

r<br />

SUPOR EMPHASIZES WORK SAfETY AND THE ENVIRONMENT<br />

Wah Hock Chia, Director of Production, Supor (China)<br />

“Supor’s work safety performance improved in 2010. This reflects <strong>the</strong> reinforcement of our work safety policy, which is <strong>the</strong><br />

subject of a monthly report to <strong>Groupe</strong> <strong>SEB</strong>. Last year we carried out an extensive programme of training and safety awareness<br />

in all our plants. We also invested in machine safety and converted certain equipment to semi-automatic mode to reduce <strong>the</strong> risk<br />

of accidents. The environment is ano<strong>the</strong>r important focus of our industrial policy. We are stepping up our efforts particularly in <strong>the</strong> areas of water and<br />

energy saving. For example, in 2010, we modernized several water treatment facilities and implemented solutions for recycling hot air from<br />

compressors for re-use in certain processes. We are working to obtain ISO 14001* and OHSAS 18001* certification for all our plants by <strong>the</strong> end of<br />

2012, in line with <strong>the</strong> Group’s standards.”