annual report annual report annual report annual report 2005

annual report annual report annual report annual report 2005

annual report annual report annual report annual report 2005

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

124<br />

MATERIAL ENGINEERING, STRUCTURAL STUDIES, DIAGNOSTICS<br />

gism of TiO 2 bound with WG-QAC. Taking into<br />

account preliminary results, TiO 2<br />

materials coated<br />

with WG-QAC seem to be very perspective to be<br />

applied as photocatalysts and photobiocatalysts.<br />

References<br />

[1]. Nilius N., Ernst N., Freund H.J.: Chem. Phys. Lett.,<br />

349, 5-6, 351-357 (2001).<br />

[2]. Kim K.D., Lee T.J., Kim H.T.: Colloids. Surf. A, 224,<br />

1-3, 1-9 (2003).<br />

[3]. Pierre A.C.: Am. Ceram. Soc. Bull., 70, 1281 (1991).<br />

[4]. Hoffmann M.R. et al.: Chem. Rev., 95, 69 (1995).<br />

[5]. Siemon U., Bahnemann D.W.: J. Photochem. Photobiol.<br />

A, 148, 247 (2002).<br />

[6]. Łukasiewicz A., Chmielewska D., Waliś L., Krajewski<br />

K.: Ekologia, 29, 3, 36-37 (<strong>2005</strong>), in Polish.<br />

METALLIC AND/OR OXYGEN ION IMPLANTATION<br />

INTO AlN CERAMICS AS A METHOD OF PREPARATION<br />

FOR ITS DIRECT BONDING WITH COPPER<br />

Marek Barlak 1/ , Wiesława Olesińska 2/ , Jerzy Piekoszewski 1,3 /, Zbigniew Werner 1,4/ ,<br />

Marcin Chmielewski 2/ , Jacek Jagielski 1,2/ , Dariusz Kaliński 2/ , Bożena Sartowska 3/ ,<br />

Katarzyna Borkowska 1/<br />

1/<br />

The Andrzej Soltan Institute for Nuclear Studies, Świerk, Poland<br />

2/<br />

Institute of Electronic Materials Technology, Warszawa, Poland<br />

3/<br />

Institute of Nuclear Chemistry and Technology, Warszawa, Poland<br />

4/<br />

Institute of Physical Chemistry, Polish Academy of Sciences, Warszawa, Poland<br />

Direct bonding (DB) process is recently getting an<br />

increasing interest as a method for producing high<br />

quality joints between aluminum nitride (AlN)<br />

ceramics and copper. Beneficial features of AlN<br />

as a substrate material for AlN-Cu joints in high<br />

power semiconductor devices are: high thermal<br />

conductivity (about 10 times higher than that for<br />

Al 2 O 3 and only about 17% lower than for toxic BeO<br />

ceramic), good electrical insulation, thermal expansion<br />

similar to silicon and non-toxicity. To form<br />

AlN-Cu joint, two prerequisites must be satisfied.<br />

Firstly, oxygen must be present in the system to<br />

allow the formation of Cu/Cu 2 O eutectic liquid<br />

(about 0.4 wt% oxygen in copper) with melting<br />

point 1065 o C, i.e. slightly below the melting point<br />

of copper. Secondly, since the surface of pure AlN<br />

is not wettable by this eutectic, this surface must<br />

be suitably modified to ensure sufficiently strong<br />

bond. Conventionally, AlN is oxidized in a furnace<br />

to convert its surface into Al 2 O 3 type, e.g. [1,2],<br />

which is wettable by Cu/Cu 2 O eutectic. Recently,<br />

we undertook a new approach to AlN pretreatment<br />

prior to DBC using ion implantation technique to<br />

form an intermediate layer between the joined elements.<br />

In the present work, we summarize the<br />

results of systematic experiments in which with<br />

such ion elements as: O, Ti, Fe, Cr and Cu were<br />

implanted in four versions into the commercial<br />

AlN substrates. For each of them, the calculations<br />

of the Gibbs free energy ∆G o was performed to<br />

facilitate the prediction of the formation of a given<br />

compound. The results are as follows:<br />

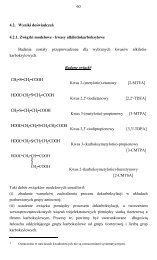

(i) Oxygen implantation<br />

+ 3/2 (O) → 1/2 + (N)<br />

∆G o 298K=-396.89 kJ/mol<br />

+ 3/2 (O) → 1/2 Al 2 O 3 + 1/2 (N 2 )<br />

∆G o 298K=-852.56 kJ/mol<br />

+ (O) → + (O)<br />

∆G o 298K=0 kJ/mol<br />

+ (O) → + 1/2 (O 2 )<br />

∆G o 298K=-262.45 kJ/mol<br />

(ii) Titanium implantation<br />

+ (Ti) → + <br />

∆G o 298K=-425.57 kJ/mol<br />

In addition, it is likely that the presence of titanium<br />

in AlN substrate can lead to creation of TiN.<br />

The value of ∆G o 298K<br />

computed for such reaction<br />

seems to confirm this possibility:<br />

+ (Ti) → + <br />

∆G o 298K=-445.91 kJ/mol<br />

(iii) O+Ti implantation<br />

Assuming that oxygen implantation may lead to<br />

Al 2 O 3 as in (i), one can expect the formation of<br />

TiO, which is well wettable by copper. Then, the<br />

calculation of Gibbs free energy gives:<br />

+ 3 → 3 + 2 <br />

∆G o 298K=-1232.66 kJ/mol<br />

From these calculations, it appears that the probability<br />

of formation of titanium lean oxides, which<br />

are not wettable, is 2 to 3 times smaller. Obviously,<br />

the formation of TiN is also possible as it was shown<br />

in (ii).<br />

(iv) Ti+O implantation<br />

In the fourth approach we intended to check<br />

whether the sequence of implantation of titanium<br />

and oxygen influences the quality of the joints. The<br />

reasoning behind this approach stems from considering<br />

case (ii), where titanium implantation<br />

leads to the formation of TiN and hence oxygen<br />

implantation as the second step will promote the<br />

formation of TiO according to the reactions:<br />

+ (O) → + (N)<br />

∆G o 298K=18.26 kJ/mol<br />

+ (O) → + (N 2 )<br />

∆G o 298K=-195.39 kJ/mol<br />

The metallic ions were implanted using an<br />

MEVVA type TITAN implanter with unseparated<br />

beam, described in detail elsewhere. Oxygen ions<br />

were implanted using a semi-industrial ion implanter<br />

without mass separation equipped with a gaseous<br />

ion source. The substrate temperature did not exceed<br />

200 o C. Ions were implanted at two accelera-