English - DFDS

English - DFDS

English - DFDS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>DFDS</strong> annual report 2009 Environmental report 43<br />

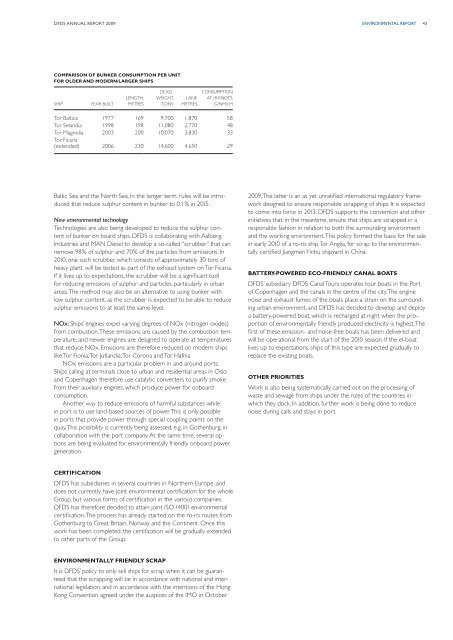

Comparison of bunker consumption per unit<br />

for older and modern/larger ships<br />

Ship<br />

Year built<br />

Length,<br />

metres<br />

Deadweight,<br />

tons<br />

Lane<br />

metres<br />

Consumption<br />

at 18 knots,<br />

g/nm/lm<br />

Tor Baltica 1977 169 9,700 1,870 58<br />

Tor Selandia 1998 198 11,080 2,770 48<br />

Tor Magnolia 2003 200 10,070 3,830 33<br />

Tor Ficaria<br />

(extended) 2006 230 14,600 4,650 29<br />

Baltic Sea and the North Sea. In the longer term, rules will be introduced<br />

that reduce sulphur content in bunker to 0.1 % in 2015.<br />

New environmental technology<br />

Technologies are also being developed to reduce the sulphur content<br />

of bunker on board ships. <strong>DFDS</strong> is collaborating with Aalborg<br />

Industries and MAN Diesel to develop a so-called “scrubber” that can<br />

remove 98 % of sulphur and 70 % of the particles from emissions. In<br />

2010, one such scrubber, which consists of approximately 30 tons of<br />

heavy plant, will be tested as part of the exhaust system on Tor Ficaria.<br />

If it lives up to expectations, the scrubber will be a significant tool<br />

for reducing emissions of sulphur and particles, particularly in urban<br />

areas. The method may also be an alternative to using bunker with<br />

low sulphur content, as the scrubber is expected to be able to reduce<br />

sulphur emissions to at least the same level.<br />

NOx: Ships’ engines expel varying degrees of NOx (nitrogen oxides)<br />

from combustion. These emissions are caused by the combustion temperature,<br />

and newer engines are designed to operate at temperatures<br />

that reduce NOx. Emissions are therefore reduced on modern ships<br />

like Tor Fionia, Tor Jutlandia, Tor Corona and Tor Hafnia.<br />

NOx emissions are a particular problem in and around ports.<br />

Ships calling at terminals close to urban and residential areas in Oslo<br />

and Copenhagen therefore use catalytic converters to purify smoke<br />

from their auxiliary engines, which produce power for onboard<br />

consumption.<br />

Another way to reduce emissions of harmful substances while<br />

in port is to use land-based sources of power. This is only possible<br />

in ports that provide power through special coupling points on the<br />

quay. This possibility is currently being assessed, e.g. in Gothenburg, in<br />

collaboration with the port company. At the same time, several options<br />

are being evaluated for environmentally friendly onboard power<br />

generation.<br />

2009. The latter is an as yet unratified international regulatory framework<br />

designed to ensure responsible scrapping of ships. It is expected<br />

to come into force in 2013. <strong>DFDS</strong> supports this convention and other<br />

initiatives that, in the meantime, ensure that ships are scrapped in a<br />

responsible fashion in relation to both the surrounding environment<br />

and the working environment. This policy formed the basis for the sale<br />

in early 2010 of a ro-ro ship, Tor Anglia, for scrap to the environmentally<br />

certified Jiangmen Yinhu shipyard in China.<br />

Battery-powered eco-friendly canal boats<br />

<strong>DFDS</strong>’ subsidiary <strong>DFDS</strong> Canal Tours operates tour boats in the Port<br />

of Copenhagen and the canals in the centre of the city. The engine<br />

noise and exhaust fumes of the boats place a strain on the surrounding<br />

urban environment, and <strong>DFDS</strong> has decided to develop and deploy<br />

a battery-powered boat, which is recharged at night when the proportion<br />

of environmentally friendly produced electricity is highest. The<br />

first of these emission- and noise-free boats has been delivered and<br />

will be operational from the start of the 2010 season. If the el-boat<br />

lives up to expectations, ships of this type are expected gradually to<br />

replace the existing boats.<br />

Other priorities<br />

Work is also being systematically carried out on the processing of<br />

waste and sewage from ships under the rules of the countries in<br />

which they dock. In addition, further work is being done to reduce<br />

noise during calls and stays in port.<br />

Certification<br />

<strong>DFDS</strong> has subsidiaries in several countries in Northern Europe, and<br />

does not currently have joint environmental certification for the whole<br />

Group, but various forms of certification in the various companies.<br />

<strong>DFDS</strong> has therefore decided to attain joint ISO 14001 environmental<br />

certification. The process has already started on the ro-ro routes from<br />

Gothenburg to Great Britain, Norway and the Continent. Once this<br />

work has been completed, the certification will be gradually extended<br />

to other parts of the Group.<br />

Environmentally friendly scrap<br />

It is <strong>DFDS</strong>’ policy to only sell ships for scrap when it can be guaranteed<br />

that the scrapping will be in accordance with national and international<br />

legislation, and in accordance with the intentions of the Hong<br />

Kong Convention agreed under the auspices of the IMO in October