Logano plus SB315, SB615, SB745 - Buderus

Logano plus SB315, SB615, SB745 - Buderus

Logano plus SB315, SB615, SB745 - Buderus

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

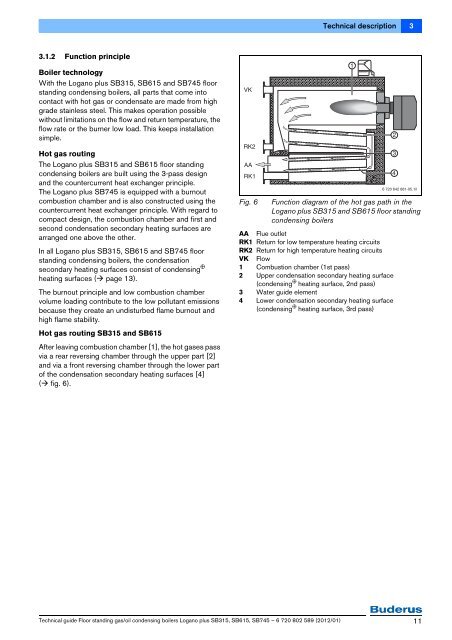

Technical description33.1.2 Function principleBoiler technologyWith the <strong>Logano</strong> <strong>plus</strong> <strong>SB315</strong>, <strong>SB615</strong> and <strong>SB745</strong> floorstanding condensing boilers, all parts that come intocontact with hot gas or condensate are made from highgrade stainless steel. This makes operation possiblewithout limitations on the flow and return temperature, theflow rate or the burner low load. This keeps installationsimple.Hot gas routingThe <strong>Logano</strong> <strong>plus</strong> <strong>SB315</strong> and <strong>SB615</strong> floor standingcondensing boilers are built using the 3-pass designand the countercurrent heat exchanger principle.The <strong>Logano</strong> <strong>plus</strong> <strong>SB745</strong> is equipped with a burnoutcombustion chamber and is also constructed using thecountercurrent heat exchanger principle. With regard tocompact design, the combustion chamber and first andsecond condensation secondary heating surfaces arearranged one above the other.In all <strong>Logano</strong> <strong>plus</strong> <strong>SB315</strong>, <strong>SB615</strong> and <strong>SB745</strong> floorstanding condensing boilers, the condensationsecondary heating surfaces consist of condensing pheating surfaces ( page 13).The burnout principle and low combustion chambervolume loading contribute to the low pollutant emissionsbecause they create an undisturbed flame burnout andhigh flame stability.Hot gas routing <strong>SB315</strong> and <strong>SB615</strong>After leaving combustion chamber [1], the hot gases passvia a rear reversing chamber through the upper part [2]and via a front reversing chamber through the lower partof the condensation secondary heating surfaces [4]( fig. 6).VKRK2AARK1Fig. 6Function diagram of the hot gas path in the<strong>Logano</strong> <strong>plus</strong> <strong>SB315</strong> and <strong>SB615</strong> floor standingcondensing boilersAA Flue outletRK1 Return for low temperature heating circuitsRK2 Return for high temperature heating circuitsVK Flow1 Combustion chamber (1st pass)2 Upper condensation secondary heating surface(condensing p heating surface, 2nd pass)3 Water guide element4 Lower condensation secondary heating surface(condensing p heating surface, 3rd pass)12346 720 642 881-05.1ilTechnical guide Floor standing gas/oil condensing boilers <strong>Logano</strong> <strong>plus</strong> <strong>SB315</strong>, <strong>SB615</strong>, <strong>SB745</strong> – 6 720 802 589 (2012/01) 11