Logano plus SB315, SB615, SB745 - Buderus

Logano plus SB315, SB615, SB745 - Buderus

Logano plus SB315, SB615, SB745 - Buderus

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

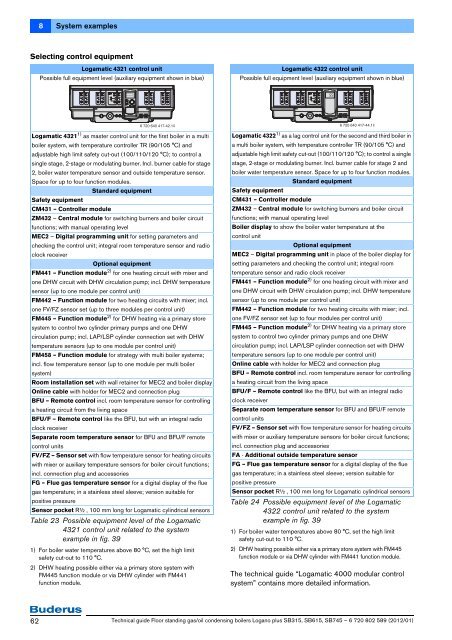

8 System examplesSelecting control equipmentLogamatic 4321 control unitPossible full equipment level (auxiliary equipment shown in blue)Logamatic 4322 control unitPossible full equipment level (auxiliary equipment shown in blue)6 720 640 417-42.1ilLogamatic 4321 1) as master control unit for the first boiler in a multiboiler system, with temperature controller TR (90/105 °C) andadjustable high limit safety cut-out (100/110/120 °C); to control asingle stage, 2-stage or modulating burner. Incl. burner cable for stage2, boiler water temperature sensor and outside temperature sensor.Space for up to four function modules.Standard equipmentSafety equipmentCM431 – Controller moduleZM432 – Central module for switching burners and boiler circuitfunctions; with manual operating levelMEC2 – Digital programming unit for setting parameters andchecking the control unit; integral room temperature sensor and radioclock receiverOptional equipmentFM441 – Function module 2) for one heating circuit with mixer andone DHW circuit with DHW circulation pump; incl. DHW temperaturesensor (up to one module per control unit)FM442 – Function module for two heating circuits with mixer; incl.one FV/FZ sensor set (up to three modules per control unit)FM445 – Function module 2) for DHW heating via a primary storesystem to control two cylinder primary pumps and one DHWcirculation pump; incl. LAP/LSP cylinder connection set with DHWtemperature sensors (up to one module per control unit)FM458 – Function module for strategy with multi boiler systems;incl. flow temperature sensor (up to one module per multi boilersystem)Room installation set with wall retainer for MEC2 and boiler displayOnline cable with holder for MEC2 and connection plugBFU – Remote control incl. room temperature sensor for controllinga heating circuit from the living spaceBFU/F – Remote control like the BFU, but with an integral radioclock receiverSeparate room temperature sensor for BFU and BFU/F remotecontrol unitsFV/FZ – Sensor set with flow temperature sensor for heating circuitswith mixer or auxiliary temperature sensors for boiler circuit functions;incl. connection plug and accessoriesFG – Flue gas temperature sensor for a digital display of the fluegas temperature; in a stainless steel sleeve; version suitable forpositive pressureSensor pocket R½ , 100 mm long for Logamatic cylindrical sensorsTable 23 Possible equipment level of the Logamatic4321 control unit related to the systemexample in fig. 391) For boiler water temperatures above 80 °C, set the high limitsafety cut-out to 110 °C.2) DHW heating possible either via a primary store system withFM445 function module or via DHW cylinder with FM441function module.6 720 640 417-44.1ilLogamatic 4322 1) as a lag control unit for the second and third boiler ina multi boiler system, with temperature controller TR (90/105 °C) andadjustable high limit safety cut-out (100/110/120 °C); to control a singlestage, 2-stage or modulating burner. Incl. burner cable for stage 2 andboiler water temperature sensor. Space for up to four function modules.Standard equipmentSafety equipmentCM431 – Controller moduleZM432 – Central module for switching burners and boiler circuitfunctions; with manual operating levelBoiler display to show the boiler water temperature at thecontrol unitOptional equipmentMEC2 – Digital programming unit in place of the boiler display forsetting parameters and checking the control unit; integral roomtemperature sensor and radio clock receiverFM441 – Function module 2) for one heating circuit with mixer andone DHW circuit with DHW circulation pump; incl. DHW temperaturesensor (up to one module per control unit)FM442 – Function module for two heating circuits with mixer; incl.one FV/FZ sensor set (up to four modules per control unit)FM445 – Function module 2) for DHW heating via a primary storesystem to control two cylinder primary pumps and one DHWcirculation pump; incl. LAP/LSP cylinder connection set with DHWtemperature sensors (up to one module per control unit)Online cable with holder for MEC2 and connection plugBFU – Remote control incl. room temperature sensor for controllinga heating circuit from the living spaceBFU/F – Remote control like the BFU, but with an integral radioclock receiverSeparate room temperature sensor for BFU and BFU/F remotecontrol unitsFV/FZ – Sensor set with flow temperature sensor for heating circuitswith mixer or auxiliary temperature sensors for boiler circuit functions;incl. connection plug and accessoriesFA - Additional outside temperature sensorFG – Flue gas temperature sensor for a digital display of the fluegas temperature; in a stainless steel sleeve; version suitable forpositive pressureSensor pocket R½ , 100 mm long for Logamatic cylindrical sensorsTable 24 Possible equipment level of the Logamatic4322 control unit related to the systemexample in fig. 391) For boiler water temperatures above 80 °C, set the high limitsafety cut-out to 110 °C.2) DHW heating possible either via a primary store system with FM445function module or via DHW cylinder with FM441 function module.The technical guide “Logamatic 4000 modular controlsystem” contains more detailed information.62Technical guide Floor standing gas/oil condensing boilers <strong>Logano</strong> <strong>plus</strong> <strong>SB315</strong>, <strong>SB615</strong>, <strong>SB745</strong> – 6 720 802 589 (2012/01)