Logano plus SB315, SB615, SB745 - Buderus

Logano plus SB315, SB615, SB745 - Buderus

Logano plus SB315, SB615, SB745 - Buderus

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

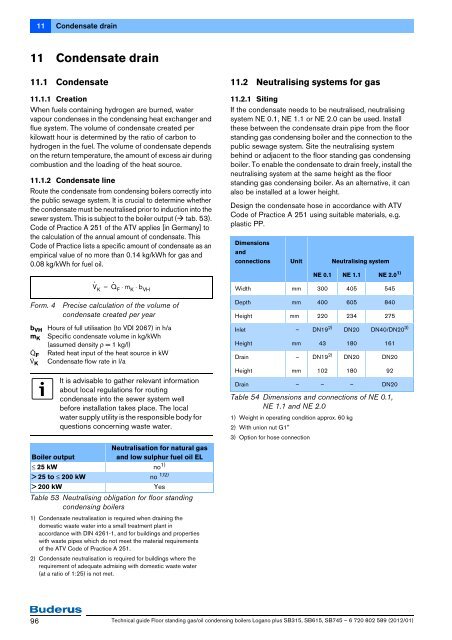

11 Condensate drain11 Condensate drain11.1 Condensate11.1.1 CreationWhen fuels containing hydrogen are burned, watervapour condenses in the condensing heat exchanger andflue system. The volume of condensate created perkilowatt hour is determined by the ratio of carbon tohydrogen in the fuel. The volume of condensate dependson the return temperature, the amount of excess air duringcombustion and the loading of the heat source.11.1.2 Condensate lineRoute the condensate from condensing boilers correctly intothe public sewage system. It is crucial to determine whetherthe condensate must be neutralised prior to induction into thesewer system. This is subject to the boiler output ( tab. 53).Code of Practice A 251 of the ATV applies [in Germany] tothe calculation of the annual amount of condensate. ThisCode of Practice lists a specific amount of condensate as anempirical value of no more than 0.14 kg/kWh for gas and0.08 kg/kWh for fuel oil.Form. 4b VHm KQ FV K. .V K= Q F⋅ m K⋅b VHPrecise calculation of the volume ofcondensate created per yearHours of full utilisation (to VDI 2067) in h/aSpecific condensate volume in kg/kWh(assumed density ρ =1kg/l)Rated heat input of the heat source in kWCondensate flow rate in l/aIt is advisable to gather relevant informationabout local regulations for routingcondensate into the sewer system wellbefore installation takes place. The localwater supply utility is the responsible body forquestions concerning waste water.Neutralisation for natural gasBoiler outputand low sulphur fuel oil EL≤ 25 kW no 1)> 25 to ≤ 200 kW no 1)2)> 200 kW YesTable 53 Neutralising obligation for floor standingcondensing boilers1) Condensate neutralisation is required when draining thedomestic waste water into a small treatment plant inaccordance with DIN 4261-1, and for buildings and propertieswith waste pipes which do not meet the material requirementsof the ATV Code of Practice A 251.2) Condensate neutralisation is required for buildings where therequirement of adequate admixing with domestic waste water(at a ratio of 1:25) is not met.11.2 Neutralising systems for gas11.2.1 SitingIf the condensate needs to be neutralised, neutralisingsystem NE 0.1, NE 1.1 or NE 2.0 can be used. Installthese between the condensate drain pipe from the floorstanding gas condensing boiler and the connection to thepublic sewage system. Site the neutralising systembehind or adjacent to the floor standing gas condensingboiler. To enable the condensate to drain freely, install theneutralising system at the same height as the floorstanding gas condensing boiler. As an alternative, it canalso be installed at a lower height.Design the condensate hose in accordance with ATVCode of Practice A 251 using suitable materials, e.g.plastic PP.Dimensionsandconnections Unit Neutralising systemNE 0.1 NE 1.1 NE 2.0 1)Width mm 300 405 545Depth mm 400 605 840Height mm 220 234 275InletHeightDrainHeight–mmDN19 2)Table 54 Dimensions and connections of NE 0.1,NE 1.1 and NE 2.01) Weight in operating condition approx. 60 kg2) With union nut G1"3) Option for hose connection–mm43DN19 2)102DN20180DN20180DN40/DN20 3)161DN20Drain – – – DN209296Technical guide Floor standing gas/oil condensing boilers <strong>Logano</strong> <strong>plus</strong> <strong>SB315</strong>, <strong>SB615</strong>, <strong>SB745</strong> – 6 720 802 589 (2012/01)