Logano plus SB315, SB615, SB745 - Buderus

Logano plus SB315, SB615, SB745 - Buderus

Logano plus SB315, SB615, SB745 - Buderus

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

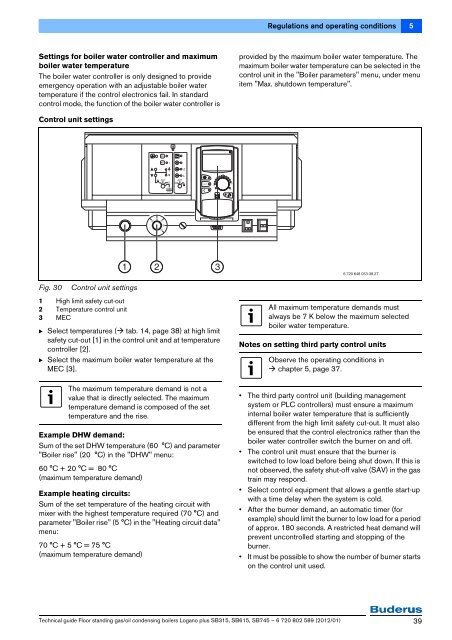

Regulations and operating conditions5Settings for boiler water controller and maximumboiler water temperatureThe boiler water controller is only designed to provideemergency operation with an adjustable boiler watertemperature if the control electronics fail. In standardcontrol mode, the function of the boiler water controller isprovided by the maximum boiler water temperature. Themaximum boiler water temperature can be selected in thecontrol unit in the "Boiler parameters" menu, under menuitem "Max. shutdown temperature".Control unit settings80Fig. 30Control unit settings1 High limit safety cut-out2 Temperature control unit3 MEC1 2 3B Select temperatures ( tab. 14, page 38) at high limitsafety cut-out [1] in the control unit and at temperaturecontroller [2].B Select the maximum boiler water temperature at theMEC [3].The maximum temperature demand is not avalue that is directly selected. The maximumtemperature demand is composed of the settemperature and the rise.Example DHW demand:Sum of the set DHW temperature (60 °C) and parameter"Boiler rise" (20 °C) in the "DHW" menu:60 °C + 20 °C = 80 °C(maximum temperature demand)Example heating circuits:Sum of the set temperature of the heating circuit withmixer with the highest temperature required (70 °C) andparameter "Boiler rise" (5 °C) in the "Heating circuit data"menu:70 °C + 5 °C = 75 °C(maximum temperature demand)6 720 648 053-38.2TAll maximum temperature demands mustalways be 7 K below the maximum selectedboiler water temperature.Notes on setting third party control unitsObserve the operating conditions in chapter 5, page 37.• The third party control unit (building managementsystem or PLC controllers) must ensure a maximuminternal boiler water temperature that is sufficientlydifferent from the high limit safety cut-out. It must alsobe ensured that the control electronics rather than theboiler water controller switch the burner on and off.• The control unit must ensure that the burner isswitched to low load before being shut down. If this isnot observed, the safety shut-off valve (SAV) in the gastrain may respond.• Select control equipment that allows a gentle start-upwith a time delay when the system is cold.• After the burner demand, an automatic timer (forexample) should limit the burner to low load for a periodof approx. 180 seconds. A restricted heat demand willprevent uncontrolled starting and stopping of theburner.• It must be possible to show the number of burner startson the control unit used.Technical guide Floor standing gas/oil condensing boilers <strong>Logano</strong> <strong>plus</strong> <strong>SB315</strong>, <strong>SB615</strong>, <strong>SB745</strong> – 6 720 802 589 (2012/01) 39