- Page 2 and 3:

FONTARGEN GmbHSiemensstraße 467304

- Page 4 and 5:

ContentsSummary in groups of FONTAR

- Page 7 and 8:

Brazing and soldering alloysa) Braz

- Page 9 and 10:

Brazing and soldering alloysd) Sold

- Page 11 and 12:

FONTARGEN A 101High strength brazin

- Page 13 and 14:

FONTARGEN A 210Brass hard solderDIN

- Page 15 and 16:

FONTARGEN A 210 MKBrazing rod with

- Page 17 and 18:

FONTARGEN A 211 RFBrass hard solder

- Page 19 and 20:

FONTARGEN A 2003Copper-phosphorus a

- Page 21 and 22:

FONTARGEN A 2005Copper-phosphorus-t

- Page 23 and 24:

FONTARGEN A 3002Silver containing c

- Page 25 and 26:

FONTARGEN A 3005 SSilver containing

- Page 27 and 28:

FONTARGEN A 3018Copper-phosphorus a

- Page 29 and 30:

FONTARGEN A 331Silver brazing alloy

- Page 31 and 32:

FONTARGEN A 311Silver brazing alloy

- Page 33 and 34:

FONTARGEN A 305Silver brazing alloy

- Page 35 and 36:

FONTARGEN A 306Silver brazing alloy

- Page 37 and 38:

FONTARGEN A 319Silver brazing alloy

- Page 39 and 40:

FONTARGEN A 320Silver brazing alloy

- Page 41 and 42:

FONTARGEN A 317Silver brazing alloy

- Page 43 and 44:

FONTARGEN A 324Silver brazing alloy

- Page 45 and 46:

FONTARGEN A 308 VSilver-Copper-Eute

- Page 47 and 48:

FONTARGEN A 341Palladium containing

- Page 49 and 50:

FONTARGEN A 345Palladium containing

- Page 51 and 52:

FONTARGEN A 407 LAluminium hard sol

- Page 53 and 54:

FONTARGEN AP 211 FMFlux containing

- Page 55 and 56:

FONTARGEN AP 2003Copper-phosphorus

- Page 58 and 59:

FONTARGEN AP 3018Copper-phosphorus

- Page 60 and 61:

FONTARGEN AP 306 FMCadmium bearing,

- Page 62 and 63:

FONTARGEN AP 320 FMCadminumfree, fl

- Page 64 and 65:

FONTARGEN AP 314 ILSilver brazing a

- Page 66 and 67:

FONTARGEN AP 317 FMFlux containing

- Page 68 and 69:

FONTARGEN AP 350 FMCadminum free, f

- Page 70 and 71:

FONTARGEN AP 46 QL/3Aluminium brazi

- Page 72 and 73:

FONTARGEN A 604Friction solderDIN E

- Page 74 and 75:

FONTARGEN A/AF 605Eutectic soft sol

- Page 76 and 77:

FONTARGEN A/AF 612Antimony-free sof

- Page 78 and 79:

FONTARGEN A 630Soft solderEN ISO 94

- Page 80 and 81:

FONTARGEN A 644Copper-bearing, lead

- Page 82 and 83:

FONTARGEN AP 604/12Tinning solderin

- Page 84 and 85:

FONTARGEN AP 638/26 NFlux containin

- Page 86 and 87:

FONTARGEN AP 644/21Lead free tin co

- Page 88 and 89:

FONTARGEN A 200 LCopper brazing all

- Page 90 and 91:

FONTARGEN A 200/2 LCopper-based hig

- Page 92 and 93:

FONTARGEN A 203/6 LCopper-based hig

- Page 94 and 95:

FONTARGEN A 205Copper-based high-te

- Page 96 and 97:

FONTARGEN AP 20 AL DBCopper high-te

- Page 98 and 99: FONTARGEN AP 21 AL CCopper high-tem

- Page 100 and 101: FONTARGEN AP 21 CLPCopper high-temp

- Page 102 and 103: FONTARGEN AP 21 DL / DSCopper- nick

- Page 104 and 105: FONTARGEN AP 21 GL / GSCopper- tin-

- Page 106 and 107: FONTARGEN AP 21 KLCopper- tin- braz

- Page 108 and 109: FONTARGEN AP 22 LLCopper- tin- braz

- Page 110 and 111: FONTARGEN HTL 1ANickel-based high-t

- Page 112 and 113: FONTARGEN HTL 2 AP (L)Nickel-based

- Page 114 and 115: FONTARGEN HTL 3Nickel-based high-te

- Page 116 and 117: FONTARGEN HTL 5 MNickel-based high-

- Page 118 and 119: FONTARGEN HTL 6 AP BNickel-based hi

- Page 120 and 121: FONTARGEN HTL 8Nickel-based high-te

- Page 122 and 123: FONTARGEN HTL 9 AP (L)Copper-based

- Page 124 and 125: FONTARGEN HTL 14Gold-based high-tem

- Page 126 and 127: FONTARGEN HTL 17Copper-based high-t

- Page 128 and 129: FONTARGEN HTL 270Nickel-based high-

- Page 130 and 131: Notes

- Page 133 and 134: Fluxesa) Brass and German silver fl

- Page 135 and 136: Silver solder fluxesin accordance w

- Page 137 and 138: Soft soldering fluxesin accordance

- Page 139 and 140: Safety precautionswhile working wit

- Page 141: Group 3MIG/MAGSolid and cored wires

- Page 144 and 145: MIG/MAG solid and cored wiredf) Cor

- Page 146 and 147: FONTARGEN A 100 AMWire electrode ma

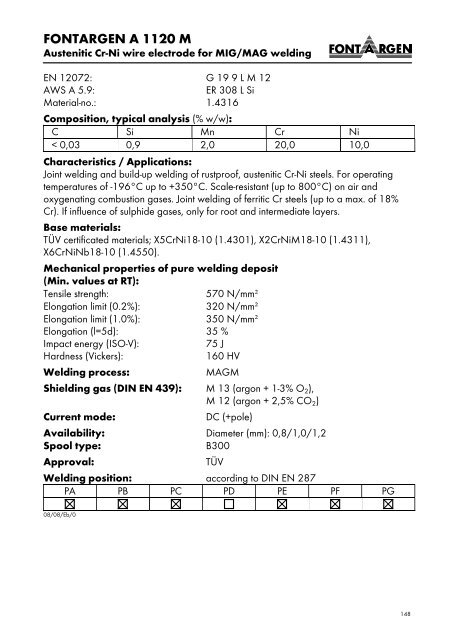

- Page 150 and 151: FONTARGEN A 1121 MCr-Ni-Mo wire ele

- Page 152 and 153: FONTARGEN A 200 MCopper wire electr

- Page 154 and 155: FONTARGEN A 202 MCopper-silicon wir

- Page 156 and 157: FONTARGEN A 207 MCu-Si-Mn wire elec

- Page 158 and 159: FONTARGEN A 203/12 MCopper-tin wire

- Page 160 and 161: FONTARGEN A 2115/8 MCopper-aluminiu

- Page 162 and 163: FONTARGEN A 512/30 MCopper-nickel w

- Page 164 and 165: FONTARGEN A 402 MAluminium-magnesiu

- Page 166 and 167: FONTARGEN A 404/4,5 MAluminium-magn

- Page 168 and 169: FONTARGEN A 405 MAluminium-silicon

- Page 170 and 171: FONTARGEN A 7101 MWire electrode of

- Page 172 and 173: FONTARGEN A 751 MFlexible wire for

- Page 174 and 175: FONTARFILL 11Metal powder flux core

- Page 176 and 177: FONTARFILL 712/600Self-shielding fl

- Page 178 and 179: FONTARFILL 7068Self-shielding corde

- Page 181 and 182: Filler rods for TIG welding and gas

- Page 183 and 184: FONTARGEN A 103 NWMolybdenum low-al

- Page 185 and 186: FONTARGEN A 1120 WCr-Ni-Mn welding

- Page 187 and 188: FONTARGEN A 521 WNickel-Chrome weld

- Page 189 and 190: FONTARGEN A 200 SWCopper-tin weldin

- Page 191 and 192: FONTARGEN A 207 WCopper-silicon-man

- Page 193 and 194: FONTARGEN A 203/12 WCopper-tin weld

- Page 195 and 196: FONTARGEN A 216 WCopper-aluminium n

- Page 197 and 198: FONTARGEN A 400 Ti WAluminium weldi

- Page 199 and 200:

FONTARGEN A 404 WAluminium-magnesiu

- Page 201 and 202:

FONTARGEN A 404/4,5 ZR WAluminium-m

- Page 203 and 204:

FONTARGEN A 407 WAluminium-silicon

- Page 205 and 206:

FONTARGEN A 850Titanium welding rod

- Page 207 and 208:

FONTARGEN A 721Welding rod for hard

- Page 209:

Group 5Stick electrodesa) Welding o

- Page 212 and 213:

FONTARGEN FE 1001DIN EN 499: E 38 2

- Page 214 and 215:

FONTARGEN FE 1010DIN EN 499: E 42 0

- Page 216 and 217:

FONTARGEN FE 1018DIN EN 499: E 42 0

- Page 218 and 219:

FONTARGEN E 1107Austenitic Cr-Ni-Mn

- Page 220 and 221:

FONTARGEN E 1125Cr-Ni-Mo stick elec

- Page 222 and 223:

FONTARGEN E 138 MoAustenitic stick

- Page 224 and 225:

FONTARGEN E 114Basic coating electr

- Page 226 and 227:

FONTARGEN E 711Hard-facing electrod

- Page 228 and 229:

FONTARGEN E 901Cutting electrode wi

- Page 230 and 231:

Notes

- Page 233 and 234:

Spraying powdera) Metal powder for

- Page 235 and 236:

FONTARGEN MP 3Metal powder for diff

- Page 237 and 238:

FONTARGEN MP 4Metal powder for diff

- Page 239 and 240:

FONTARGEN MP 5 FMetal powder for di

- Page 241 and 242:

FONTARGEN FM 2Metal powder for flam

- Page 243 and 244:

FONTARGEN FM 4Metal powder for flam

- Page 245:

Group 7Special productsa) FONTARFIX

- Page 248 and 249:

FONTARGEN FONTARFIXFONTARFIX is an

- Page 250 and 251:

FONTARGEN FONTEX NEPickling powder

- Page 252 and 253:

FONTARGEN FONTINOX FRSurface cleane

- Page 254 and 255:

FONTARGEN Neutralisation pasteThe n

- Page 256 and 257:

FONTARGEN cleaning and degreasing s

- Page 258 and 259:

Notes

- Page 261 and 262:

Welding of low- and high-alloyed st

- Page 263 and 264:

Welding of low- and high-alloyed st

- Page 265 and 266:

Welding of cold-tough steel and cas

- Page 267 and 268:

Welding of nickel and nickel alloys

- Page 269 and 270:

Welding of copper and copper alloys

- Page 271 and 272:

Welding of copper and copper alloys

- Page 273 and 274:

Welding of aluminium and aluminium

- Page 275 and 276:

Physical property values of some al

- Page 277 and 278:

Notes

- Page 279 and 280:

Notes

- Page 281:

All information concerning our prod