You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Application Limits<br />

Useful time for prepared product - Pot life<br />

Pre-dry time<br />

Opening the traffic<br />

Full curing<br />

The foregoing values represent the results of the laboratory tests conducted at 23 ± 2°C<br />

temperature and 50% ± 5 relative humidity conditions. The values provided as per the table<br />

may vary depending on the surface and ambient conditions.<br />

APPLICATION INSTRUCTIONS<br />

Mixing Ratio<br />

Component A (4.650 kg) and component B (0.350 kg) should be thoroughly mixed.<br />

Mixing Equipment<br />

• Low speed electrical mixer (400 cycles/min.)<br />

• Special tip stirring equipment<br />

Maximum 60 minutes<br />

Minimum 5 hours<br />

Minimum 24 hours<br />

Minimum 7 days<br />

Mixing Period<br />

The product should be mixed with a low speed mixer for 3 to 5 minutes until a homogenous<br />

mixture is obtained.<br />

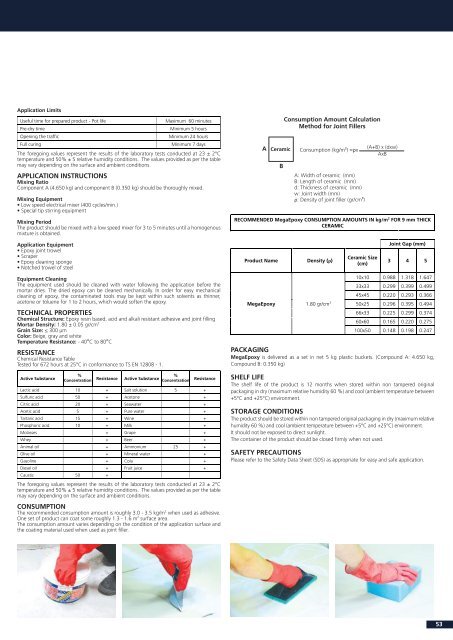

A<br />

Ceramic<br />

B<br />

Consumption Amount Calculation<br />

Method for Joint Fillers<br />

Consumption (kg/m2) =ρx<br />

A: Width of ceramic (mm)<br />

B: Length of ceramic (mm)<br />

d: Thickness of ceramic (mm)<br />

w: Joint width (mm)<br />

ρ: Density of joint filler (gr/cm3)<br />

(A+B) x (dxw)<br />

AxB<br />

RECOMMENDED MegaEpoxy CONSUMPTION AMOUNTS IN kg/m 2 FOR 9 mm THICK<br />

CERAMIC<br />

Application Equipment<br />

• Epoxy joint trowel<br />

• Scraper<br />

• Epoxy cleaning sponge<br />

• Notched trowel of steel<br />

Product Name<br />

Density (ρ)<br />

Ceramic Size<br />

(cm)<br />

Joint Gap (mm)<br />

3 4 5<br />

Equipment Cleaning<br />

The equipment used should be cleaned with water following the application before the<br />

mortar dries. The dried epoxy can be cleaned mechanically. In order for easy mechanical<br />

cleaning of epoxy, the contaminated tools may be kept within such solvents as thinner,<br />

acetone or toluene for 1 to 2 hours, which would soften the epoxy.<br />

TECHNICAL PROPERTIES<br />

Chemical Structure: Epoxy resin based, acid and alkali resistant adhesive and joint filling<br />

Mortar Density: 1.80 ± 0.05 gr/cm 3<br />

Grain Size: ≤ 300 µm<br />

Color: Beige, gray and white<br />

Temperature Resistance: - 40°C to 80°C<br />

RESISTANCE<br />

Chemical Resistance Table<br />

Tested for 672 hours at 25°C in conformance to TS EN 12808 - 1.<br />

Active Substance<br />

%<br />

Concentration Resistance Active Substance %<br />

Concentration Resistance<br />

Lactic acid 10 + Salt solution 5 +<br />

Sulfuric acid 50 + Acetone +<br />

Citric acid 20 + Seawater +<br />

Acetic acid 5 + Pure water +<br />

Tartaric acid 15 + Wine +<br />

Phosphoric acid 10 + Milk +<br />

Molasses + Grape +<br />

Whey + Beer +<br />

Animal oil + Ammonium 25 +<br />

Olive oil + Mineral water +<br />

Gasoline + Cola +<br />

Diesel oil + Fruit juice +<br />

Caustic 50 +<br />

The foregoing values represent the results of the laboratory tests conducted at 23 ± 2°C<br />

temperature and 50% ± 5 relative humidity conditions. The values provided as per the table<br />

may vary depending on the surface and ambient conditions.<br />

CONSUMPTION<br />

The recommended consumption amount is roughly 3.0 - 3.5 kg/m 2 when used as adhesive.<br />

One set of product can coat some roughly 1.3 - 1.6 m 2 surface area.<br />

The consumption amount varies depending on the condition of the application surface and<br />

the coating material used when used as joint filler.<br />

MegaEpoxy 1.80 gr/cm 3<br />

10x10 0.988 1.318 1.647<br />

33x33 0.299 0.399 0.499<br />

45x45 0.220 0.293 0.366<br />

50x25 0.296 0.395 0.494<br />

66x33 0.225 0.299 0.374<br />

60x60 0.165 0.220 0.275<br />

100x50 0.148 0.198 0.247<br />

PACKAGING<br />

MegaEpoxy is delivered as a set in net 5 kg plastic buckets. (Compound A: 4.650 kg,<br />

Compound B: 0.350 kg)<br />

SHELF LIFE<br />

The shelf life of the product is 12 months when stored within non tampered original<br />

packaging in dry (maximum relative humidity 60 %) and cool (ambient temperature between<br />

+5°C and +25°C) environment.<br />

STORAGE CONDITIONS<br />

The product should be stored within non tampered original packaging in dry (maximum relative<br />

humidity 60 %) and cool (ambient temperature between +5°C and +25°C) environment.<br />

It should not be exposed to direct sunlight.<br />

The container of the product should be closed firmly when not used.<br />

SAFETY PRECAUTIONS<br />

Please refer to the Safety Data Sheet (SDS) as appropriate for easy and safe application.<br />

53