The Delft Sand, Clay & Rock Cutting Model, 2019a

The Delft Sand, Clay & Rock Cutting Model, 2019a

The Delft Sand, Clay & Rock Cutting Model, 2019a

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>The</strong> <strong>Delft</strong> <strong>Sand</strong>, <strong>Clay</strong> & <strong>Rock</strong> <strong>Cutting</strong> <strong>Model</strong>.<br />

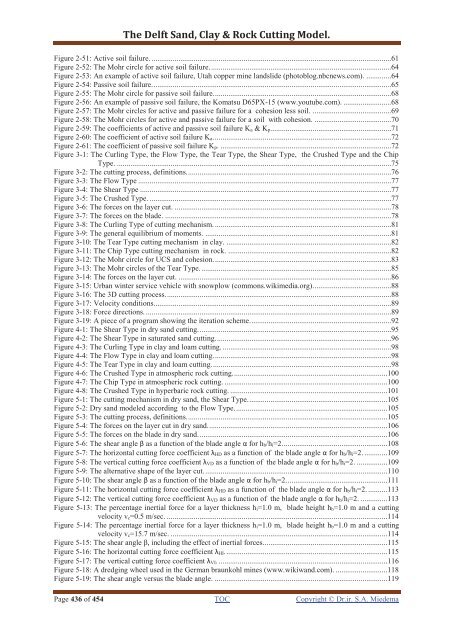

Figure 2-51: Active soil failure. .............................................................................................................................61<br />

Figure 2-52: <strong>The</strong> Mohr circle for active soil failure. ..............................................................................................64<br />

Figure 2-53: An example of active soil failure, Utah copper mine landslide (photoblog.nbcnews.com). .............64<br />

Figure 2-54: Passive soil failure. ............................................................................................................................65<br />

Figure 2-55: <strong>The</strong> Mohr circle for passive soil failure. ............................................................................................68<br />

Figure 2-56: An example of passive soil failure, the Komatsu D65PX-15 (www.youtube.com). .........................68<br />

Figure 2-57: <strong>The</strong> Mohr circles for active and passive failure for a cohesion less soil. .........................................69<br />

Figure 2-58: <strong>The</strong> Mohr circles for active and passive failure for a soil with cohesion. ........................................70<br />

Figure 2-59: <strong>The</strong> coefficients of active and passive soil failure K a & K p. ..............................................................71<br />

Figure 2-60: <strong>The</strong> coefficient of active soil failure K a. ............................................................................................72<br />

Figure 2-61: <strong>The</strong> coefficient of passive soil failure K p. .........................................................................................72<br />

Figure 3-1: <strong>The</strong> Curling Type, the Flow Type, the Tear Type, the Shear Type, the Crushed Type and the Chip<br />

Type. ...............................................................................................................................................75<br />

Figure 3-2: <strong>The</strong> cutting process, definitions. ..........................................................................................................76<br />

Figure 3-3: <strong>The</strong> Flow Type ....................................................................................................................................77<br />

Figure 3-4: <strong>The</strong> Shear Type ...................................................................................................................................77<br />

Figure 3-5: <strong>The</strong> Crushed Type. ..............................................................................................................................77<br />

Figure 3-6: <strong>The</strong> forces on the layer cut. .................................................................................................................78<br />

Figure 3-7: <strong>The</strong> forces on the blade. ......................................................................................................................78<br />

Figure 3-8: <strong>The</strong> Curling Type of cutting mechanism. ............................................................................................81<br />

Figure 3-9: <strong>The</strong> general equilibrium of moments. .................................................................................................81<br />

Figure 3-10: <strong>The</strong> Tear Type cutting mechanism in clay. ......................................................................................82<br />

Figure 3-11: <strong>The</strong> Chip Type cutting mechanism in rock. .....................................................................................82<br />

Figure 3-12: <strong>The</strong> Mohr circle for UCS and cohesion. ............................................................................................83<br />

Figure 3-13: <strong>The</strong> Mohr circles of the Tear Type. ...................................................................................................85<br />

Figure 3-14: <strong>The</strong> forces on the layer cut. ...............................................................................................................86<br />

Figure 3-15: Urban winter service vehicle with snowplow (commons.wikimedia.org). ........................................88<br />

Figure 3-16: <strong>The</strong> 3D cutting process. .....................................................................................................................88<br />

Figure 3-17: Velocity conditions............................................................................................................................89<br />

Figure 3-18: Force directions. ................................................................................................................................89<br />

Figure 3-19: A piece of a program showing the iteration scheme. .........................................................................92<br />

Figure 4-1: <strong>The</strong> Shear Type in dry sand cutting. ....................................................................................................95<br />

Figure 4-2: <strong>The</strong> Shear Type in saturated sand cutting. ...........................................................................................96<br />

Figure 4-3: <strong>The</strong> Curling Type in clay and loam cutting. ........................................................................................98<br />

Figure 4-4: <strong>The</strong> Flow Type in clay and loam cutting. ............................................................................................98<br />

Figure 4-5: <strong>The</strong> Tear Type in clay and loam cutting. .............................................................................................98<br />

Figure 4-6: <strong>The</strong> Crushed Type in atmospheric rock cutting. ................................................................................100<br />

Figure 4-7: <strong>The</strong> Chip Type in atmospheric rock cutting. .....................................................................................100<br />

Figure 4-8: <strong>The</strong> Crushed Type in hyperbaric rock cutting. ..................................................................................101<br />

Figure 5-1: <strong>The</strong> cutting mechanism in dry sand, the Shear Type. ........................................................................105<br />

Figure 5-2: Dry sand modeled according to the Flow Type. ...............................................................................105<br />

Figure 5-3: <strong>The</strong> cutting process, definitions. ........................................................................................................105<br />

Figure 5-4: <strong>The</strong> forces on the layer cut in dry sand. .............................................................................................106<br />

Figure 5-5: <strong>The</strong> forces on the blade in dry sand. ..................................................................................................106<br />

Figure 5-6: <strong>The</strong> shear angle β as a function of the blade angle α for h b/h i=2. ......................................................108<br />

Figure 5-7: <strong>The</strong> horizontal cutting force coefficient λ HD as a function of the blade angle α for h b/h i=2. ............109<br />

Figure 5-8: <strong>The</strong> vertical cutting force coefficient λ VD as a function of the blade angle α for h b/h i=2. ................109<br />

Figure 5-9: <strong>The</strong> alternative shape of the layer cut. ...............................................................................................110<br />

Figure 5-10: <strong>The</strong> shear angle β as a function of the blade angle α for h b/h i=2. ....................................................111<br />

Figure 5-11: <strong>The</strong> horizontal cutting force coefficient λ HD as a function of the blade angle α for h b/h i=2. ..........113<br />

Figure 5-12: <strong>The</strong> vertical cutting force coefficient λ VD as a function of the blade angle α for h b/h i=2. ..............113<br />

Figure 5-13: <strong>The</strong> percentage inertial force for a layer thickness h i=1.0 m, blade height h b=1.0 m and a cutting<br />

velocity v c=0.5 m/sec. ...................................................................................................................114<br />

Figure 5-14: <strong>The</strong> percentage inertial force for a layer thickness h i=1.0 m, blade height h b=1.0 m and a cutting<br />

velocity v c=15.7 m/sec. .................................................................................................................114<br />

Figure 5-15: <strong>The</strong> shear angle β, including the effect of inertial forces.................................................................115<br />

Figure 5-16: <strong>The</strong> horizontal cutting force coefficient λ HI. ....................................................................................115<br />

Figure 5-17: <strong>The</strong> vertical cutting force coefficient λ VI. ........................................................................................116<br />

Figure 5-18: A dredging wheel used in the German braunkohl mines (www.wikiwand.com). ...........................118<br />

Figure 5-19: <strong>The</strong> shear angle versus the blade angle. ..........................................................................................119<br />

Page 436 of 454 TOC Copyright © Dr.ir. S.A. Miedema