HANSA 05-2019

Nor-Shipping ’19 | Maritime Hub Norway | Finanzplatz Oslo | Tugs & Salvage | HullPIC | Offshore-Logistik | NordLB | Breakbulk Europe | Hansa Heavy Lift | HS Schiffahrt | MPP-Carrier

Nor-Shipping ’19 | Maritime Hub Norway | Finanzplatz Oslo | Tugs & Salvage | HullPIC | Offshore-Logistik | NordLB | Breakbulk Europe | Hansa Heavy Lift | HS Schiffahrt | MPP-Carrier

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Schiffstechnik | Ship Technology<br />

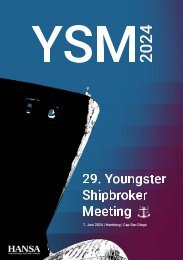

A colorful hybrid<br />

The charge is building up: The progress of the »Color Hybrid« ship construction in spring<br />

<strong>2019</strong> has been steady, and the plug-in hybrid vessel is getting prepared to enter service in<br />

June with a lot of innovative technology on board<br />

For a long time, Ulstein Verft’s yard<br />

number 311, the »Color Hybrid«, has<br />

been hiding in the dock hall. Now it has<br />

been painted and launched. The delivery<br />

is scheduled for May <strong>2019</strong> to enter service<br />

in June, so the waiting for the world’s<br />

largest plug-in hybrid vessel will be over<br />

soon. The environmentally sound ship<br />

will be servicing the 38nm route between<br />

Sandefjord – Strømstad (crossing time<br />

2,5 hours) from summer <strong>2019</strong>. Ulstein<br />

won the contract in competition with several<br />

other yards. In Februabry 2017, Color<br />

Line and Ulstein Verft signed the contract<br />

on construction of the 30,000 GT ship designed<br />

by Fosen Yard.<br />

The new RoPax cruiseferry uses new<br />

solutions to reduce noise and emissions.<br />

The vessel features a diesel-electric plugin<br />

hybrid concept with PTO/PTI allowing<br />

for hybrid propulsion using both direct-drive<br />

and electric. Siemens batteries<br />

installed in four battery rooms in the machinery<br />

area deliver a combined capacity<br />

of 4.7 MWh.<br />

At vessel speeds up to 12 kn, the<br />

5 MWh battery package weighing almost<br />

70 t is going to allow for 60 minutes<br />

of fully electric operation. In normal<br />

operation the vessel’s top speed is 17 kn.<br />

The battery system was delivered by Siemens,<br />

who manufactured the batteries at<br />

its new production facility in Trondheim.<br />

Siemens is well-known for being a key<br />

supplier for ferry operator Scandlines’<br />

hybrid ferry »Berlin« (196 m, 1,600 lane<br />

meters), which is in service in the Baltic<br />

since 2016 and uses batteries with a<br />

combined capacity of 4.5 MWh. The energy<br />

management system for this vessel<br />

and her sister ship »Copenhagen« already<br />

came from Siemens, while the batteries<br />

came from Corvus Energy.<br />

The batteries are recharged via a power<br />

cable with »green« electricity from<br />

shore facilities or, as a secondary alternative,<br />

recharged on board by the ship’s<br />

generators. With shore power provided<br />

in Sandefjord, all Norwegian ports<br />

on Color Line’s network will have shore<br />

power facilities. The ship will have full<br />

battery power into and out of the fjord to<br />

Sandefjord inner harbour. It will therefore<br />

not give emissions of harmful greenhouse<br />

gases or nitrogen and sulphur compounds<br />

in this area.<br />

The ship is equipped with four Rolls-<br />

Royce Bergen B33:45L in-line diesel engines<br />

of which two are B:33:45L6 (six cylinders,<br />

3,600 kW) and two are B33:45L8<br />

(eight cylinders, 4,800 kW). The four engines<br />

were delivered in March 2018, the<br />

contract came with an option to provide<br />

engines for a second vessel. The »Color<br />

Hybrid’s« engine and energy layout also<br />

features a waste-heat recovery system.<br />

Norwegian company Brunvoll supplied<br />

the propulsion package including<br />

controllable pitch propellers and tunnel<br />

thrusters, gearboxes, rudders and steering<br />

gear. Besides the two CP-propellers,<br />

Brunvoll delivered two fixed-pitch propeller<br />

tunnel thrusters and one rim-driven,<br />

permanent magnet tunnel thruster as<br />

well as control systems for propulsion,<br />

positioning and manoeuvring.<br />

A »local« project<br />

Steel cutting started in July 2017, in April<br />

2018 Crist shipyard in Gdynia, Poland,<br />

began to assemble the 14 blocks of the<br />

ship’s hull. After the hull was completed<br />

it was then towed to Ulsteinvik in November<br />

2018 for outfitting.<br />

According to Ulstein, »Color Hybrid«<br />

is a good example of the interaction in the<br />

© Color Line<br />

14<br />

<strong>HANSA</strong> International Maritime Journal <strong>05</strong> | <strong>2019</strong> NorShipping