- Page 1 and 2:

Rock Mechanics

- Page 3 and 4:

Rock Mechanics for underground mini

- Page 5 and 6:

Contents Preface to the third editi

- Page 7 and 8:

CONTENTS 9 Excavation design in blo

- Page 9 and 10:

CONTENTS ix Appendix A Basic constr

- Page 11 and 12:

PREFACE TO THE THIRD EDITION Mining

- Page 13 and 14:

PREFACE TO THE SECOND EDITION In th

- Page 15 and 16:

PREFACE TO THE FIRST EDITION design

- Page 17 and 18:

ACKNOWLEDGEMENTS Safety in Mines Re

- Page 19 and 20:

Figure 1.1 (a) Pre-mining condition

- Page 21 and 22:

ROCK MECHANICS AND MINING ENGINEERI

- Page 23 and 24:

ROCK MECHANICS AND MINING ENGINEERI

- Page 25 and 26:

Figure 1.4 Principal features of a

- Page 27 and 28:

10 Figure 1.5 Definition of activit

- Page 29 and 30:

ROCK MECHANICS AND MINING ENGINEERI

- Page 31 and 32:

Figure 1.7 Components and logic of

- Page 33 and 34:

ROCK MECHANICS AND MINING ENGINEERI

- Page 35 and 36:

Figure 2.1 (a) A finite body subjec

- Page 37 and 38:

Figure 2.2 Free-body diagram for es

- Page 39 and 40:

STRESS AND INFINITESIMAL STRAIN As

- Page 41 and 42:

STRESS AND INFINITESIMAL STRAIN In

- Page 43 and 44:

Figure 2.3 Free-body diagram for de

- Page 45 and 46:

Figure 2.5 Problem geometry for det

- Page 47 and 48:

Figure 2.7 Rigid-body rotation of a

- Page 49 and 50:

STRESS AND INFINITESIMAL STRAIN the

- Page 51 and 52:

STRESS AND INFINITESIMAL STRAIN str

- Page 53 and 54:

⎡ ⎢ ⎣ xx yy zz xy yz zx STRES

- Page 55 and 56:

Figure 2.11 Cylindrical polar coord

- Page 57 and 58:

STRESS AND INFINITESIMAL STRAIN fre

- Page 59 and 60:

Figure 2.13 Construction of a Mohr

- Page 61 and 62:

STRESS AND INFINITESIMAL STRAIN fun

- Page 63 and 64:

3 Rock Figure 3.1 Sidewall failure

- Page 65 and 66:

Figure 3.2 Jointing in a folded str

- Page 67 and 68:

Figure 3.5 Diagrammatic longitudina

- Page 69 and 70:

Figure 3.7 Discontinuity spacing hi

- Page 71 and 72:

Figure 3.9 Illustration of persiste

- Page 73 and 74:

Figure 3.11 Typical roughness profi

- Page 75 and 76:

ROCK MASS STRUCTURE AND CHARACTERIS

- Page 77 and 78:

ROCK MASS STRUCTURE AND CHARACTERIS

- Page 79 and 80:

ROCK MASS STRUCTURE AND CHARACTERIS

- Page 81 and 82:

Figure 3.17 Sample number vs. preci

- Page 83 and 84:

Figure 3.19 Diagrammatic illustrati

- Page 85 and 86:

ROCK MASS STRUCTURE AND CHARACTERIS

- Page 87 and 88:

Figure 3.20 Computerised depiction

- Page 89 and 90:

Figure 3.23 Stereographic projectio

- Page 91 and 92:

Figure 3.26 Polar stereographic net

- Page 93 and 94:

Figure 3.28 Contours of pole concen

- Page 95 and 96: ROCK MASS STRUCTURE AND CHARACTERIS

- Page 97 and 98: ROCK MASS STRUCTURE AND CHARACTERIS

- Page 99 and 100: Figure 3.30 Geological Strength Ind

- Page 101 and 102: ROCK MASS STRUCTURE AND CHARACTERIS

- Page 103 and 104: Figure 4.1 Idealised illustration o

- Page 105 and 106: ROCK STRENGTH AND DEFORMABILITY wit

- Page 107 and 108: Figure 4.4 Influence of end restrai

- Page 109 and 110: ROCK STRENGTH AND DEFORMABILITY whe

- Page 111 and 112: Figure 4.8 Principle of closed-loop

- Page 113 and 114: Figure 4.12 Two classes of stress-

- Page 115 and 116: Figure 4.14 Point load test apparat

- Page 117 and 118: Figure 4.15 Biaxial compression tes

- Page 119 and 120: Figure 4.18 Results of triaxial com

- Page 121 and 122: ROCK STRENGTH AND DEFORMABILITY was

- Page 123 and 124: Figure 4.23 Coulomb strength envelo

- Page 125 and 126: Figure 4.25 Extension of a preexist

- Page 127 and 128: Figure 4.29 The three basic modes o

- Page 129 and 130: Figure 4.30 Normalised peak strengt

- Page 131 and 132: ROCK STRENGTH AND DEFORMABILITY Tab

- Page 133 and 134: Figure 4.32 The normality condition

- Page 135 and 136: Figure 4.33 Variation of peak princ

- Page 137 and 138: Figure 4.35 Direct shear test confi

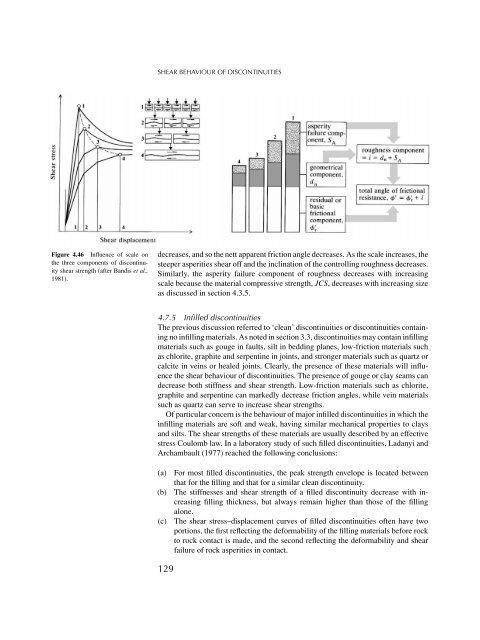

- Page 139 and 140: Figure 4.37 Shear stress-shear disp

- Page 141 and 142: Figure 4.40 Peak and residual effec

- Page 143 and 144: Figure 4.43 Effect of shearing dire

- Page 145: Figure 4.45 Relations between norma

- Page 149 and 150: ROCK STRENGTH AND DEFORMABILITY whe

- Page 151 and 152: Figure 4.49 Composite peak strength

- Page 153 and 154: Figure 4.50 Hoek-Brown peak strengt

- Page 155 and 156: Figure 4.52 Determination of the Yo

- Page 157 and 158: ROCK STRENGTH AND DEFORMABILITY 4 A

- Page 159 and 160: 5 Pre-mining Figure 5.1 Method of s

- Page 161 and 162: Figure 5.2 The effect of irregular

- Page 163 and 164: PRE-MINING STATE OF STRESS surround

- Page 165 and 166: PRE-MINING STATE OF STRESS induced

- Page 167 and 168: Figure 5.5 (a) Definition of hole l

- Page 169 and 170: Figure 5.6 (a) Core drilling a slot

- Page 171 and 172: Figure 5.7 Principles of stress mea

- Page 173 and 174: PRE-MINING STATE OF STRESS strength

- Page 175 and 176: PRE-MINING STATE OF STRESS A second

- Page 177 and 178: PRE-MINING STATE OF STRESS by the e

- Page 179 and 180: PRE-MINING STATE OF STRESS extend i

- Page 181 and 182: PRE-MINING STATE OF STRESS (d) Dete

- Page 183 and 184: METHODS OF STRESS ANALYSIS quantita

- Page 185 and 186: METHODS OF STRESS ANALYSIS It is in

- Page 187 and 188: Figure 6.2 A thick-walled cylinder

- Page 189 and 190: METHODS OF STRESS ANALYSIS For the

- Page 191 and 192: Figure 6.3 Problem geometry, coordi

- Page 193 and 194: Figure 6.4 Problem geometry, coordi

- Page 195 and 196: METHODS OF STRESS ANALYSIS When the

- Page 197 and 198:

Figure 6.5 Superposition scheme dem

- Page 199 and 200:

METHODS OF STRESS ANALYSIS The disc

- Page 201 and 202:

Figure 6.7 Development of a finite

- Page 203 and 204:

METHODS OF STRESS ANALYSIS Solution

- Page 205 and 206:

Figure 6.8 A simple finite element

- Page 207 and 208:

Figure 6.9 A schematic representati

- Page 209 and 210:

METHODS OF STRESS ANALYSIS block ce

- Page 211 and 212:

METHODS OF STRESS ANALYSIS where ˚

- Page 213 and 214:

METHODS OF STRESS ANALYSIS The prin

- Page 215 and 216:

EXCAVATION DESIGN IN MASSIVE ELASTI

- Page 217 and 218:

Figure 7.2 A logical framework for

- Page 219 and 220:

Figure 7.3 (a) Axisymmetric stress

- Page 221 and 222:

Figure 7.6 A plane of weakness, ori

- Page 223 and 224:

Figure 7.8 A flat-lying plane of we

- Page 225 and 226:

Figure 7.10 Shear stress/normal str

- Page 227 and 228:

Figure 7.12 Ovaloidal opening in a

- Page 229 and 230:

Figure 7.15 States of stress at sel

- Page 231 and 232:

Figure 7.16 Prediction of the exten

- Page 233 and 234:

Figure 7.18 Contour plots of princi

- Page 235 and 236:

Figure 7.19 Problem geometry for de

- Page 237 and 238:

EXCAVATION DESIGN IN MASSIVE ELASTI

- Page 239 and 240:

EXCAVATION DESIGN IN MASSIVE ELASTI

- Page 241 and 242:

8 Excavation Figure 8.1 An excavati

- Page 243 and 244:

EXCAVATION DESIGN IN STRATIFIED ROC

- Page 245 and 246:

Figure 8.4 Experimental apparatus f

- Page 247 and 248:

Figure 8.7 Free body diagrams and n

- Page 249 and 250:

Figure 8.8 Assumed distributions of

- Page 251 and 252:

Figure 8.9 Flow chart for the deter

- Page 253 and 254:

Figure 8.10 Normalised arch thickne

- Page 255 and 256:

EXCAVATION DESIGN IN STRATIFIED ROC

- Page 257 and 258:

Figure 8.11 Normalised deflection a

- Page 259 and 260:

9 Excavation Figure 9.1 Generation

- Page 261 and 262:

Figure 9.3 (a) A finite, non-tapere

- Page 263 and 264:

(a) (b) Figure 9.4 (a) Vertical cro

- Page 265 and 266:

(a) (b) (c) EP EP Reference circle

- Page 267 and 268:

Figure 9.10 JP 100 is the only JP w

- Page 269 and 270:

Figure 9.12 Traces of the views of

- Page 271 and 272:

EXCAVATION DESIGN IN BLOCKY ROCK In

- Page 273 and 274:

Figure 9.14 Free-body diagrams of a

- Page 275 and 276:

EXCAVATION DESIGN IN BLOCKY ROCK di

- Page 277 and 278:

Figure 9.16 Symmetrical wedge in th

- Page 279 and 280:

Figure 9.17 (a) Geometry for determ

- Page 281 and 282:

Figure 9.18 Problem geometry demons

- Page 283 and 284:

Figure 9.20 Cut-and-fill stope mine

- Page 285 and 286:

Figure 9.22 Chart to determine fact

- Page 287 and 288:

EXCAVATION DESIGN IN BLOCKY ROCK Th

- Page 289 and 290:

Figure 10.1 (a) Pre-mining state of

- Page 291 and 292:

Figure 10.3 (a) Dynamic loading of

- Page 293 and 294:

Figure 10.5 (a) Pre-mining and (b)

- Page 295 and 296:

Figure 10.6 Problem definition and

- Page 297 and 298:

ENERGY, MINE STABILITY, MINE SEISMI

- Page 299 and 300:

Figure 10.9 Force and stress compon

- Page 301 and 302:

ENERGY, MINE STABILITY, MINE SEISMI

- Page 303 and 304:

ENERGY, MINE STABILITY, MINE SEISMI

- Page 305 and 306:

ENERGY, MINE STABILITY, MINE SEISMI

- Page 307 and 308:

Figure 10.12 Distribution of radial

- Page 309 and 310:

Figure 10.15 Problem geometry for d

- Page 311 and 312:

Figure 10.17 (a) Schematic represen

- Page 313 and 314:

ENERGY, MINE STABILITY, MINE SEISMI

- Page 315 and 316:

Figure 10.20 Elastic/post-peak stif

- Page 317 and 318:

ENERGY, MINE STABILITY, MINE SEISMI

- Page 319 and 320:

Figure 10.24 Relation between frequ

- Page 321 and 322:

ENERGY, MINE STABILITY, MINE SEISMI

- Page 323 and 324:

ENERGY, MINE STABILITY, MINE SEISMI

- Page 325 and 326:

Figure 10.28 Six possible ways that

- Page 327 and 328:

Figure 10.29 First motions for P an

- Page 329 and 330:

11Rock support and reinforcement 11

- Page 331 and 332:

Figure 11.1 (a) Hypothetical exampl

- Page 333 and 334:

Figure 11.4 Non-linear support reac

- Page 335 and 336:

Figure 11.5 Idealised elastic-britt

- Page 337 and 338:

Figure 11.6 Calculated required sup

- Page 339 and 340:

ROCK SUPPORT AND REINFORCEMENT The

- Page 341 and 342:

Figure 11.9 Ground reaction curves

- Page 343 and 344:

Figure 11.12 Use of grouted reinfor

- Page 345 and 346:

ROCK SUPPORT AND REINFORCEMENT If,

- Page 347 and 348:

Figure 11.16 Local reinforcement ac

- Page 349 and 350:

Figure 11.18 Typical working sketch

- Page 351 and 352:

Figure 11.19 Permanent support and

- Page 353 and 354:

Figure 11.22 Basis of natural coord

- Page 355 and 356:

Figure 11.24 Distributions of (a) s

- Page 357 and 358:

Figure 11.26 Resin grouted rockbolt

- Page 359 and 360:

Figure 11.28 Alternative methods of

- Page 361 and 362:

ROCK SUPPORT AND REINFORCEMENT Tabl

- Page 363 and 364:

Figure 11.31 Toussaint-Heintzmann y

- Page 365 and 366:

MINING METHODS AND METHOD SELECTION

- Page 367 and 368:

Figure 12.2 Elements of a supported

- Page 369 and 370:

MINING METHODS AND METHOD SELECTION

- Page 371 and 372:

MINING METHODS AND METHOD SELECTION

- Page 373 and 374:

MINING METHODS AND METHOD SELECTION

- Page 375 and 376:

Figure 12.6 Schematic layout for bi

- Page 377 and 378:

Figure 12.8 Layout for shrink stopi

- Page 379 and 380:

Figure 12.9 Schematic layout for VC

- Page 381 and 382:

Figure 12.11 Key elements of longwa

- Page 383 and 384:

Figure 12.13 Mining layout for tran

- Page 385 and 386:

MINING METHODS AND METHOD SELECTION

- Page 387 and 388:

13 Figure 13.1 Schematic illustrati

- Page 389 and 390:

Figure 13.3 Layout of barrier pilla

- Page 391 and 392:

Figure 13.5 Principal modes of defo

- Page 393 and 394:

Figure 13.8 Geometry for tributary

- Page 395 and 396:

PILLAR SUPPORTED MINING METHODS str

- Page 397 and 398:

Figure 13.10 Distribution of vertic

- Page 399 and 400:

Figure 13.12 Pillar behaviour domai

- Page 401 and 402:

PILLAR SUPPORTED MINING METHODS Lun

- Page 403 and 404:

Figure 13.15 Options in the design

- Page 405 and 406:

Figure 13.17 Relation between yield

- Page 407 and 408:

Figure 13.19 Model of yield of coun

- Page 409 and 410:

Figure 13.20 North-south vertical c

- Page 411 and 412:

Figure 13.23 Stope-and-pillar layou

- Page 413 and 414:

Figure 13.25 Calibrated stability c

- Page 415 and 416:

PILLAR SUPPORTED MINING METHODS wor

- Page 417 and 418:

Figure 13.28 Pillar performance, de

- Page 419 and 420:

Figure 13.29 (a) Stope and pillar l

- Page 421 and 422:

Figure 13.31 (a) Plane strain analy

- Page 423 and 424:

PILLAR SUPPORTED MINING METHODS Pan

- Page 425 and 426:

14 Artificially supported mining me

- Page 427 and 428:

ARTIFICIALLY SUPPORTED MINING METHO

- Page 429 and 430:

ARTIFICIALLY SUPPORTED MINING METHO

- Page 431 and 432:

Figure 14.2 Simplified view of stru

- Page 433 and 434:

ARTIFICIALLY SUPPORTED MINING METHO

- Page 435 and 436:

Figure 14.5 Confined block model fo

- Page 437 and 438:

Figure 14.7 Crown and sidewall stre

- Page 439 and 440:

ARTIFICIALLY SUPPORTED MINING METHO

- Page 441 and 442:

ARTIFICIALLY SUPPORTED MINING METHO

- Page 443 and 444:

Figure 14.10 Sublevel open stoping

- Page 445 and 446:

Figure 14.12 Some applications of c

- Page 447 and 448:

15 Longwall and caving mining metho

- Page 449 and 450:

Figure 15.2 Shear stress drop in th

- Page 451 and 452:

LONGWALL AND CAVING MINING METHODS

- Page 453 and 454:

LONGWALL AND CAVING MINING METHODS

- Page 455 and 456:

Figure 15.6 Hydraulic prop reaction

- Page 457 and 458:

Figure 15.7 Development and extract

- Page 459 and 460:

Figure 15.8 Vertical stress redistr

- Page 461 and 462:

Figure 15.11 Distribution of observ

- Page 463 and 464:

Figure 15.13 Plan view of microseis

- Page 465 and 466:

Figure 15.16 Ground-support interac

- Page 467 and 468:

Figure 15.18 Roadway support and re

- Page 469 and 470:

LONGWALL AND CAVING MINING METHODS

- Page 471 and 472:

LONGWALL AND CAVING MINING METHODS

- Page 473 and 474:

LONGWALL AND CAVING MINING METHODS

- Page 475 and 476:

Figure 15.25 Comparison of isolated

- Page 477 and 478:

Figure 15.26 Geometry of a sublevel

- Page 479 and 480:

Figure 15.28 Theoretical determinat

- Page 481 and 482:

Figure 15.31 Deterioration of a cro

- Page 483 and 484:

Figure 15.32 Distinct element simul

- Page 485 and 486:

LONGWALL AND CAVING MINING METHODS

- Page 487 and 488:

Figure 15.34 Extended Mathews stabi

- Page 489 and 490:

Figure 15.36 Comparison of postand

- Page 491 and 492:

LONGWALL AND CAVING MINING METHODS

- Page 493 and 494:

Figure 15.39 Idealised plan illustr

- Page 495 and 496:

Figure 15.41 Idealised vertical sec

- Page 497 and 498:

Figure 15.42 Vertical slice through

- Page 499 and 500:

LONGWALL AND CAVING MINING METHODS

- Page 501 and 502:

16 Figure 16.1 Trough subsidence ov

- Page 503 and 504:

MINING-INDUCED SURFACE SUBSIDENCE c

- Page 505 and 506:

Figure 16.4 North-south section, At

- Page 507 and 508:

Figure 16.6 (a) Rectangular block g

- Page 509 and 510:

MINING-INDUCED SURFACE SUBSIDENCE f

- Page 511 and 512:

Figure 16.8 Relation between stope

- Page 513 and 514:

MINING-INDUCED SURFACE SUBSIDENCE M

- Page 515 and 516:

MINING-INDUCED SURFACE SUBSIDENCE

- Page 517 and 518:

Figure 16.14 Chart developed to est

- Page 519 and 520:

Figure 16.16 Progressive hangingwal

- Page 521 and 522:

Figure 16.19 Idealised model used i

- Page 523 and 524:

Figure 16.21 Longitudinal section,

- Page 525 and 526:

MINING-INDUCED SURFACE SUBSIDENCE t

- Page 527 and 528:

MINING-INDUCED SURFACE SUBSIDENCE w

- Page 529 and 530:

MINING-INDUCED SURFACE SUBSIDENCE F

- Page 531 and 532:

Figure 16.25 Subsidence troughs pre

- Page 533 and 534:

Figure 16.28 Predicted and measured

- Page 535 and 536:

17 Blasting mechanics 17.1 Blasting

- Page 537 and 538:

Figure 17.1 An empirical matching o

- Page 539 and 540:

Figure 17.2 A finite difference mod

- Page 541 and 542:

Figure 17.4 Reflection of a cylindr

- Page 543 and 544:

BLASTING MECHANICS means that no ci

- Page 545 and 546:

Figure 17.8 Layout of blast holes i

- Page 547 and 548:

Figure 17.9 Influence of field stat

- Page 549 and 550:

Figure 17.11 Generation of surface

- Page 551 and 552:

BLASTING MECHANICS The components o

- Page 553 and 554:

BLASTING MECHANICS amplitudes of th

- Page 555 and 556:

BLASTING MECHANICS 17.9 Evaluation

- Page 557 and 558:

Figure 17.15 (a) Schematic cross se

- Page 559 and 560:

BLASTING MECHANICS in Figure 17.17,

- Page 561 and 562:

MONITORING ROCK MASS PERFORMANCE (a

- Page 563 and 564:

MONITORING ROCK MASS PERFORMANCE su

- Page 565 and 566:

MONITORING ROCK MASS PERFORMANCE Ta

- Page 567 and 568:

Figure 18.2 The Distometer ISETH, a

- Page 569 and 570:

Figure 18.5 Self-inductance multipl

- Page 571 and 572:

MONITORING ROCK MASS PERFORMANCE is

- Page 573 and 574:

Figure 18.9 Biaxial vibrating wire

- Page 575 and 576:

MONITORING ROCK MASS PERFORMANCE me

- Page 577 and 578:

Figure 18.12 Cross section at 6650N

- Page 579 and 580:

Figure 18.13 Examples of convergenc

- Page 581 and 582:

Figure 18.15 Longitudinal section l

- Page 583 and 584:

Figure 18.16 (Cont.) MONITORING ROC

- Page 585 and 586:

Appendix A Basic constructions usin

- Page 587 and 588:

Figure A.3 Determining the angle be

- Page 589 and 590:

APPENDIX A USE OF HEMISPHERICAL PRO

- Page 591 and 592:

APPENDIX B STRESSES AND DISPLACEMEN

- Page 593 and 594:

Figure A.6 Axisymmetric tunnel prob

- Page 595 and 596:

Figure A.9 Bolt load-extension curv

- Page 597 and 598:

APPENDIX D LIMITING EQUILIBRIUM ANA

- Page 599 and 600:

APPENDIX D LIMITING EQUILIBRIUM ANA

- Page 601 and 602:

APPENDIX D LIMITING EQUILIBRIUM ANA

- Page 603 and 604:

ANSWERS TO PROBLEMS 2 (a) 0.087 - 0

- Page 605 and 606:

ANSWERS TO PROBLEMS 3 wp = 38.6 m,

- Page 607 and 608:

REFERENCES Symp. & 17th Tunn. Assn

- Page 609 and 610:

REFERENCES Brady, B. H. G. and Bray

- Page 611 and 612:

REFERENCES Collier, P. A. (1993) De

- Page 613 and 614:

REFERENCES Drescher, A. and Vardoul

- Page 615 and 616:

REFERENCES Gustafsson, P. (1998) Wa

- Page 617 and 618:

REFERENCES Hood, M. and Brown, E. T

- Page 619 and 620:

REFERENCES Kaiser, P. K. and Tannan

- Page 621 and 622:

REFERENCES Lorig, L. J. and Brady,

- Page 623 and 624:

REFERENCES Ortlepp, W. D. (1994) Gr

- Page 625 and 626:

REFERENCES Rojas, E., Molina, R. an

- Page 627 and 628:

REFERENCES Spottiswoode, S. M. and

- Page 629 and 630:

REFERENCES Villaescusa, E., Windsor

- Page 631 and 632:

Index Page numbers appearing in bol

- Page 633 and 634:

INDEX Coulomb (cont.) parameters 96

- Page 635 and 636:

INDEX Excavation (cont.) support ra

- Page 637 and 638:

INDEX Jaeger’s plane of weakness

- Page 639 and 640:

INDEX Panel caving 470-2, 473, 474,

- Page 641 and 642:

INDEX Seismic (cont.) moment 306, 3

- Page 643 and 644:

INDEX Strength (cont.) residual 86,

- Page 645:

INDEX United States (USA) 395, 396,