- Page 1 and 2:

ILLINOIS SITE REMEDIATION PROGRAM C

- Page 3 and 4:

TABLE OF CONTENTS EXECUTIVE SUMMARY

- Page 5 and 6:

APPENDICES Appendix A Historical Do

- Page 7 and 8:

The far northeast Former Clark Stat

- Page 9 and 10:

‣ Tier 2 soil component of the Cl

- Page 11 and 12:

Section 4 - Documentation of Field

- Page 13 and 14:

Physical Setting Sources: • Berg,

- Page 15 and 16:

The Will Silty Clay Loam is a poorl

- Page 17 and 18:

Groundwater Classification: The sat

- Page 19 and 20:

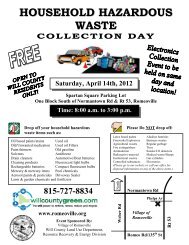

y Dalhart Avenue to the west, Norma

- Page 21 and 22:

The soil gas samples were submitted

- Page 23 and 24:

3.3 INVESTIGATION MONITORING AND EQ

- Page 25 and 26:

casing volumes and allowed to recha

- Page 27 and 28:

Summary results of analyses are pre

- Page 29 and 30:

4.3 REC 1 - FORMER DRY CLEANING OPE

- Page 31 and 32:

5.0 ENDANGERMENT ASSESSMENT The Sit

- Page 33 and 34:

5.3 SITE RECOGNIZED ENVIRONMENTAL C

- Page 35 and 36:

• There is no evidence of hazardo

- Page 37 and 38:

As summarized in (Tables 1.1, 2.1 t

- Page 39 and 40:

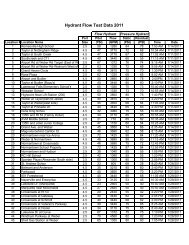

‣ The Village of Romeoville maint

- Page 41 and 42:

A Tier 1 RO evaluation of Site data

- Page 43 and 44:

FIIGURES

- Page 45 and 46:

± Various Retail & Commercial Busi

- Page 47 and 48:

FIGgwcontour07292.dgn 5/14/2010 12:

- Page 49 and 50:

FIGRECs07292.dgn 5/16/2010 1:07:17

- Page 51 and 52:

FIGbor_exceed07292.dgn 5/19/2010 4:

- Page 53 and 54:

TABLES

- Page 55 and 56:

Table 1.1 Summary of Soil and Groun

- Page 57 and 58:

TABLE 2.1 - SOIL ANALYTICAL RESULTS

- Page 59 and 60:

TABLE 2.2 - SOIL ANALYTICAL RESULTS

- Page 61 and 62:

TABLE 2.4 - SOIL ANALYTICAL RESULTS

- Page 63 and 64:

Volatile Organic Compounds (Method

- Page 65 and 66:

TABLE 3.2 - GROUNDWATER ANALYTICAL

- Page 67 and 68:

Chemical Name and Soil Remediation

- Page 144 and 145:

February 13, 2008 Ms. Dawn Caldwell

- Page 146 and 147:

SIGNATURES OF ENVIRONMENTAL PROFESS

- Page 148 and 149:

LIST OF APPENDICES Appendix I Quali

- Page 150 and 151:

material risk of harm to public hea

- Page 152 and 153:

terms with Village of Romeoville. T

- Page 154 and 155:

The following published documents w

- Page 156 and 157:

An ALTA/ACSM Land Title Survey was

- Page 158 and 159:

Hydrogeology: Based on regional top

- Page 160 and 161:

The EDR database report identified

- Page 162 and 163:

One site was identified as part of

- Page 164 and 165:

Multiple historical sources were re

- Page 166 and 167:

Independence Boulevard followed by

- Page 168 and 169:

All tenants Mexican Restaurant Laun

- Page 170 and 171:

Parking lot, northeast of building

- Page 172 and 173:

8.0 FINDINGS, OPINIONS & CONCLUSION

- Page 174 and 175:

± Approximate Site Boundary V3 Com

- Page 176 and 177:

± Spartans' Square Shopping Center

- Page 178 and 179:

Ms. Dawn Caldwell Village of Romeov

- Page 180 and 181:

Ms. Dawn Caldwell Village of Romeov

- Page 182 and 183:

FIIGURES

- Page 184 and 185:

± Approximate Site Boundary Variou

- Page 186 and 187:

TABLES

- Page 188 and 189:

TABLE 2 - GROUNDWATER ANALYTICAL RE

- Page 190 and 191:

10173 V3 Boring Log Report Boring N

- Page 192 and 193:

10193 V3 Boring Log Report Boring N

- Page 194 and 195:

10209 V3 Boring Log Report Boring N

- Page 196 and 197:

10225 V3 Boring Log Report Boring N

- Page 198 and 199:

10247 V3 Boring Log Report Boring N

- Page 200 and 201:

CHAIN-OF-CUSTODY PROTOCOL Laborator

- Page 202 and 203:

DECONTAMINATION ACTIVITIES PROTOCOL

- Page 204 and 205:

• Depth at which saturated condit

- Page 236 and 237:

BEACON Report No. 2096 PASSIVE SOIL

- Page 238 and 239:

BEACON Report Number: 2096 Passive

- Page 240 and 241:

BEACON ENVIRONMENTAL SERVICES, INC.

- Page 242 and 243:

Table 1 Beacon Environmental Servic

- Page 244 and 245:

Table 1 Beacon Environmental Servic

- Page 246 and 247:

Table 1 Beacon Environmental Servic

- Page 248 and 249:

MW-9 Asphalt Parking Lot Sanitary S

- Page 250 and 251:

MW-9 Asphalt Parking Lot Sanitary S

- Page 252 and 253:

Attachments

- Page 254 and 255:

BEACON PSG SAMPLER DEPLOYMENT THROU

- Page 258 and 259:

Attachment 3 LABORATORY PROCEDURES

- Page 262:

APPENDIIX B WELL SURVEY DOCUMENTATI

- Page 273 and 274:

Well ID Well Description Status Dep

- Page 275:

minimum protection zones are regula

- Page 291 and 292:

Well Survey Correspondence Spatans'

- Page 293 and 294:

10233 V3 Boring Log Report Spartans

- Page 295 and 296:

10258 V3 Boring Log Report Spartans

- Page 297 and 298:

10277 V3 Boring Log Report Spartans

- Page 299 and 300:

10184 V3 Boring Log Report Spartans

- Page 301 and 302:

10200 V3 Boring Log Report Spartans

- Page 303 and 304:

10216 V3 Boring Log Report Spartans

- Page 305 and 306:

10234 V3 Boring Log Report Spartans

- Page 307 and 308:

10252 V3 Boring Log Report Spartans

- Page 309 and 310:

10271 V3 Boring Log Report Spartans

- Page 311 and 312:

10288 V3 Boring Log Report Spartans

- Page 313 and 314:

10304 V3 Boring Log Report Spartans

- Page 315 and 316:

10321 V3 Boring Log Report Spartans

- Page 317 and 318:

10337 V3 Boring Log Report Spartans

- Page 319 and 320:

10353 V3 Boring Log Report Spartans

- Page 321 and 322:

10233 V3 Boring Log Report Spartans

- Page 323 and 324:

10255 V3 Boring Log Report Spartans

- Page 325 and 326:

10275 V3 Boring Log Report Spartans

- Page 327 and 328:

10294 V3 Boring Log Report Spartans

- Page 329 and 330:

10313 V3 Boring Log Report Spartans

- Page 331 and 332:

10331 V3 Boring Log Report Spartans

- Page 333 and 334:

APPENDIIX D PHOTOGRAPHIC DOCUMENTAT

- Page 335 and 336:

PHOTO 4 Date:11/18/2008 Installatio

- Page 358 and 359:

Prairie Analytical Systems, Inc. CL

- Page 360 and 361:

Prairie Analytical Systems, Inc. Da

- Page 362 and 363:

Prairie Analytical Systems, Inc. Da

- Page 364 and 365:

Prairie Analytical Systems, Inc. Da

- Page 366 and 367:

Prairie Analytical Systems, Inc. Da

- Page 368 and 369:

Prairie Analytical Systems, Inc. Qu

- Page 370 and 371:

CLIENT: Illinois Environmental Prot

- Page 372 and 373:

CLIENT: Illinois Environmental Prot

- Page 374 and 375:

CLIENT: Illinois Environmental Prot

- Page 376 and 377:

CLIENT: Illinois Environmental Prot

- Page 378 and 379:

CLIENT: Illinois Environmental Prot

- Page 380 and 381:

CLIENT: Illinois Environmental Prot

- Page 382:

CLIENT: Illinois Environmental Prot

- Page 441 and 442:

Illinois Environmental Protection A

- Page 443 and 444:

Illinois Environmental Protection A

- Page 445 and 446:

Illinois Environmental Protection A

- Page 447 and 448:

Illinois Environmental Protection A

- Page 449 and 450:

Illinois Environmental Protection A

- Page 451 and 452:

Illinois Environmental Protection A

- Page 453 and 454:

Illinois Environmental Protection A

- Page 455 and 456:

Illinois Environmental Protection A

- Page 457 and 458:

Illinois Environmental Protection A

- Page 459 and 460:

Illinois Environmental Protection A

- Page 461 and 462:

Illinois Environmental Protection A

- Page 463 and 464:

Illinois Environmental Protection A

- Page 465 and 466:

Illinois Environmental Protection A

- Page 467 and 468:

Illinois Environmental Protection A

- Page 469 and 470:

Illinois Environmental Protection A

- Page 471 and 472:

Illinois Environmental Protection A

- Page 473 and 474:

Illinois Environmental Protection A

- Page 475 and 476:

Illinois Environmental Protection A

- Page 477 and 478:

Illinois Environmental Protection A

- Page 479 and 480:

Illinois Environmental Protection A

- Page 481 and 482:

Illinois Environmental Protection A

- Page 483 and 484:

Illinois Environmental Protection A

- Page 485 and 486:

Illinois Environmental Protection A

- Page 487 and 488:

Illinois Environmental Protection A

- Page 489 and 490:

Illinois Environmental Protection A

- Page 491 and 492:

Illinois Environmental Protection A

- Page 493 and 494:

Illinois Environmental Protection A

- Page 495 and 496:

Illinois Environmental Protection A

- Page 497 and 498:

Illinois Environmental Protection A

- Page 499 and 500:

Illinois Environmental Protection A

- Page 501 and 502:

Illinois Environmental Protection A

- Page 503 and 504:

Illinois Environmental Protection A

- Page 505 and 506:

Illinois Environmental Protection A

- Page 507 and 508:

Illinois Environmental Protection A

- Page 509 and 510:

Illinois Environmental Protection A

- Page 511 and 512:

Illinois Environmental Protection A

- Page 513 and 514:

Illinois Environmental Protection A

- Page 515 and 516:

Illinois Environmental Protection A

- Page 517 and 518:

Illinois Environmental Protection A

- Page 519 and 520:

Illinois Environmental Protection A

- Page 521 and 522:

Illinois Environmental Protection A

- Page 523 and 524:

Illinois Environmental Protection A

- Page 525 and 526:

Illinois Environmental Protection A

- Page 527 and 528:

Illinois Environmental Protection A

- Page 529 and 530:

Illinois Environmental Protection A

- Page 531 and 532:

Illinois Environmental Protection A

- Page 533 and 534:

Illinois Environmental Protection A

- Page 535 and 536:

Illinois Environmental Protection A

- Page 537 and 538:

Illinois Environmental Protection A

- Page 539 and 540:

Illinois Environmental Protection A

- Page 541 and 542:

Illinois Environmental Protection A

- Page 543 and 544:

Illinois Environmental Protection A

- Page 545 and 546:

Illinois Environmental Protection A

- Page 547 and 548:

Illinois Environmental Protection A

- Page 549 and 550:

Illinois Environmental Protection A

- Page 551 and 552:

Illinois Environmental Protection A

- Page 553 and 554:

Illinois Environmental Protection A

- Page 555 and 556:

Illinois Environmental Protection A

- Page 557 and 558:

Illinois Environmental Protection A

- Page 559 and 560:

Illinois Environmental Protection A

- Page 561 and 562:

Illinois Environmental Protection A

- Page 563 and 564:

Illinois Environmental Protection A

- Page 565 and 566:

Illinois Environmental Protection A

- Page 567 and 568:

Illinois Environmental Protection A

- Page 569 and 570:

Illinois Environmental Protection A

- Page 571 and 572:

Illinois Environmental Protection A

- Page 573 and 574:

Illinois Environmental Protection A

- Page 575 and 576:

Illinois Environmental Protection A

- Page 577 and 578:

Illinois Environmental Protection A

- Page 579 and 580:

Illinois Environmental Protection A

- Page 581 and 582:

Illinois Environmental Protection A

- Page 583 and 584:

Illinois Environmental Protection A

- Page 585 and 586:

Illinois Environmental Protection A

- Page 587 and 588:

Illinois Environmental Protection A

- Page 589 and 590:

Illinois Environmental Protection A

- Page 591 and 592:

Illinois Environmental Protection A

- Page 593 and 594:

Illinois Environmental Protection A

- Page 595 and 596:

Illinois Environmental Protection A

- Page 597 and 598:

Illinois Environmental Protection A

- Page 599 and 600:

Illinois Environmental Protection A

- Page 601 and 602:

Illinois Environmental Protection A

- Page 603 and 604:

Illinois Environmental Protection A

- Page 605 and 606:

Illinois Environmental Protection A

- Page 607 and 608:

Illinois Environmental Protection A

- Page 609 and 610:

Illinois Environmental Protection A

- Page 611 and 612:

Illinois Environmental Protection A

- Page 613 and 614:

Illinois Environmental Protection A

- Page 615 and 616:

Illinois Environmental Protection A

- Page 617 and 618:

Illinois Environmental Protection A

- Page 619 and 620:

Illinois Environmental Protection A

- Page 621 and 622:

Illinois Environmental Protection A

- Page 623 and 624:

Illinois Environmental Protection A

- Page 625 and 626: Illinois Environmental Protection A

- Page 627 and 628: Illinois Environmental Protection A

- Page 629 and 630: Illinois Environmental Protection A

- Page 631 and 632: Illinois Environmental Protection A

- Page 633 and 634: Illinois Environmental Protection A

- Page 635 and 636: Illinois Environmental Protection A

- Page 637 and 638: Illinois Environmental Protection A

- Page 639 and 640: Illinois Environmental Protection A

- Page 641 and 642: Illinois Environmental Protection A

- Page 643 and 644: Illinois Environmental Protection A

- Page 645 and 646: Illinois Environmental Protection A

- Page 647 and 648: Illinois Environmental Protection A

- Page 649 and 650: Illinois Environmental Protection A

- Page 651 and 652: Illinois Environmental Protection A

- Page 653 and 654: Illinois Environmental Protection A

- Page 655 and 656: Illinois Environmental Protection A

- Page 657 and 658: Illinois Environmental Protection A

- Page 659 and 660: Illinois Environmental Protection A

- Page 661 and 662: Illinois Environmental Protection A

- Page 663 and 664: Illinois Environmental Protection A

- Page 665 and 666: Illinois Environmental Protection A

- Page 667 and 668: Illinois Environmental Protection A

- Page 669 and 670: CHAIN-OF-CUSTODY PROTOCOL Laborator

- Page 671 and 672: DECONTAMINATION ACTIVITIES PROTOCOL

- Page 673 and 674: • Drilling method • Depth at wh

- Page 675: to collect the soil sample from the

- Page 679: Page 2 of 2 Purging will be perform