FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

-2 3 4 5 6 7 8 9 10 11 12<br />

BEND RADIUS (mm)<br />

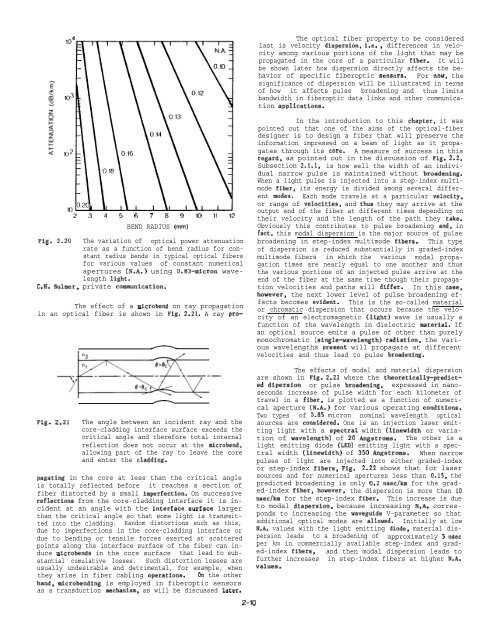

Fig. 2.20 The variation of optical power attenuation<br />

rate as a function of bend radius for constant<br />

radius bends in typical optical fibers<br />

for various values of constant numerical<br />

apertures (N.A.) using 0.83-micron wavelength<br />

light.<br />

C.H. Bulmer, private communication.<br />

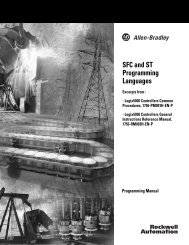

Fig. 2.21<br />

The effect of a microbend on ray propagation<br />

in an optical fiber is shown in Fig. 2.21. A ray pro-<br />

+==2si-<br />

The angle between an incident ray and the<br />

core-cladding interface surface exceeds the<br />

critical angle and therefore total internal<br />

reflection does not occur at the microbend,<br />

allowing part of the ray to leave the core<br />

and enter the cladding.<br />

pagating in the core at less than the critical angle<br />

is totally reflected before it reaches a section of<br />

fiber distorted by a small imperfection. On successive<br />

reflections from the core-cladding interface it is incident<br />

at an angle with the interface surface larger<br />

than the critical angle so that some light is transmitted<br />

into the cladding. Random distortions such as this,<br />

due to imperfections in the core-cladding interface or<br />

due to bending or tensile forces exerted at scattered<br />

points along the interface surface of the fiber can induce<br />

microbends in the core surface that lead to substantial<br />

cumulative losses. Such distortion losses are<br />

usually undesirable and detrimental, for example, when<br />

they arise in fiber cabling operations. on the other<br />

hand, microbending is employed in fiberoptic sensors<br />

as a transduction mechanism, as will be discussed later.<br />

2-1o<br />

The optical fiber property to be considered<br />

last is velocity dispersion, i.e. , differences in velocity<br />

among various portions of the light that may be<br />

propagated in the core of a particular fiber. It will<br />

be shown later how dispersion directly affects the behavior<br />

of specific fiberoptic sensors. For now, the<br />

significance of dispersion will be illustrated in terms<br />

of how it affects pulse broadening and thus limits<br />

bandwidth in fiberoptic data links and other communication<br />

applications.<br />

In the introduction to this chapter, it was<br />

pointed out that one of the aims of the optical-fiber<br />

designer is to design a fiber that will preserve the<br />

information impressed on a beam of light as it propagates<br />

through its core. A measure of success in this<br />

regard, as pointed out in the discussion of Fig. 2.2,<br />

Subsection 2.1.1, is how well the width of an individual<br />

narrow pulse is maintained without broadening.<br />

When a light pulse is injected into a step-index multimode<br />

fiber, its energy is divided among several different<br />

modes. Each mode travels at a particular velocity,<br />

or range of velocities, and thua they may arrive at the<br />

output end of the fiber at different times depending on<br />

their velocity and the length of the path they take.<br />

Obviously this contributes to pulse broadening and, in<br />

fact, this modal dispersion is the major source of pulse<br />

broadening in step-index multimode fibers. This type<br />

of dispersion is reduced substantially in graded-index<br />

multimode fibers in which the various modal propagation<br />

times are nearly equal to one another and thus<br />

the various portions of an injected pulse arrive at the<br />

end of the fiber at the same time though their propagation<br />

velocities and paths will differ. In this case,<br />

however, the next lower level of pulse broadening effects<br />

becomes evident. This is the so-called material<br />

or chromatic dispersion that occurs because the velocity<br />

of an electromagnetic (light) wave is usually a<br />

function of the wavelength in dielectric material. If<br />

an optical source emits a pulse of other than purely<br />

monochromatic (single-wavelength) radiation, the various<br />

wavelengths preaent will propagate at different<br />

velocities and thus lead to pulse broadening.<br />

The effects of modal and material dispersion<br />

are shown in Fig. 2.22 where the theoretically-predicted<br />

dipersion or pulse broadening, expressed in nanoseconds<br />

increase of pulse width for each kilometer of<br />

travel in a fiber, is plotted as a function of numerical<br />

aperture (N.A.) for various operating conditions.<br />

Two types of 0.85 micron nominal wavelength optical<br />

sources are considered. One is an injection laser emitting<br />

light with a apectral width (linewidth or variation<br />

of wavelength) of 20 Angstroms. The other is a<br />

light emitting diode (LED) emitting light with a spectral<br />

width (linewidth) of 350 Angstroms. When narrow<br />

pulses of light are injected into either graded-index<br />

or step-index fibers, Fig. 2.22 shows that for laser<br />

sources and for numerical apertures less than 0.15, the<br />

predicted broadening is only 0.2 nsec/km for the graded-index<br />

fiber, however, the dispersion is more than 10<br />

nsecfkm for the step-index fiber. This increase is due<br />

to modal diaperaion, because increasing N.A. corresponds<br />

to increasing the waveguide V-parameter so that<br />

additional optical modes are allowed. Initially at low<br />

N.A. values with the light emitting diode, material dispersion<br />

leads to a broadening of approximately 5 nsec<br />

per km in commercially available step-index and graded-index<br />

fibers,<br />

further increases<br />

values.<br />

and then modal dispersion leads to<br />

in step-index fibers at higher N.A.