FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

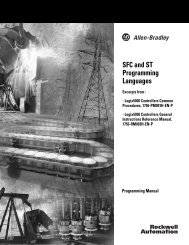

technique is also shown in Fig. 3.6. The fiber is<br />

lightly scored and then pulled. Care must be taken so<br />

as not to bend the fiber. If the fiber bends a lip<br />

tends to form when it breaks and a smooth endface does<br />

A)STRIPJACKET<br />

B)SCORE<br />

~FILE<br />

t<br />

FIBER<br />

6 ?<br />

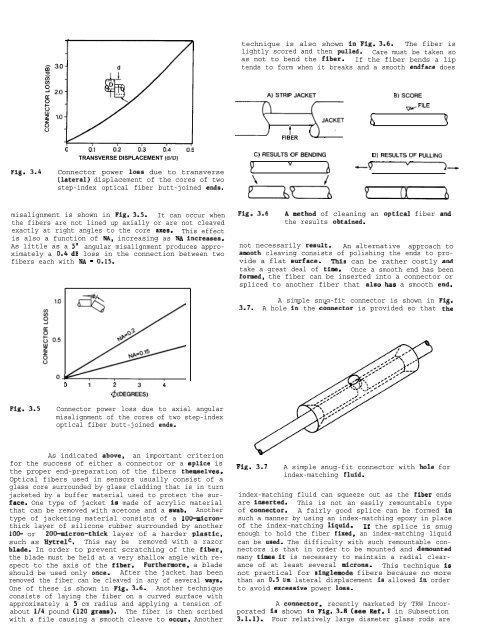

Fig. 3.4<br />

o 0.1 0.2 0.3 0.4 0:5<br />

TRANSVERSE DISPLACEMENT (d/D)<br />

Connector power loss due to transverse<br />

(lateral) displacement of the cores of two<br />

step-index optical fiber butt-joined enda.<br />

P<br />

C) RESULTS OFFENDING<br />

v<br />

&d<br />

h<br />

D) RESULTS OF PULLING<br />

—~.<br />

misalignment is shown in Fig. 3.5. It can occur when<br />

the fibers are not lined up axially or are not cleaved<br />

exactly at right angles to the core axes. This effect<br />

is also a function of NA, increasing as NA increases.<br />

As little as a 5° angular misalignment produces approximately<br />

a 0.4 dB loss in the connection between two<br />

fibers each with NA = 0.15.<br />

Fig. 3.6<br />

A method of cleaning an optical fiber and<br />

the results obtained.<br />

not necessarily result. An alternative approach to<br />

amooth cleaving consists of polishing the ends to provide<br />

a flat surface. This can be rather costly and”<br />

take a great deal of time. Once a smooth end has been<br />

formed, the fiber can be inserted into a connector or<br />

spliced to another fiber that alao haa a smooth end.<br />

A simple snug-fit connector is shown in Flz.<br />

3.7. A hole in- the c&nector is provided so that tie<br />

o 1“ 4<br />

~(DEGR&<br />

Fig. 3.5<br />

Connector power loss due to axial angular<br />

misalignment of the cores of two step-index<br />

optical fiber butt-joined ends.<br />

As indicated above, an important criterion<br />

for the success of either a connector or a splice is<br />

the proper end-preparation of the fibers themselves.<br />

Optical fibers used in sensors usually consist of a<br />

glass core surrounded by glass cladding that is in turn<br />

jacketed by a buffer material used to protect the surface.<br />

One type of jacket is made of acrylic material<br />

that can be removed with acetone and a swab. Another<br />

type of jacketing material consists of a IOO-micronthick<br />

layer of silicone rubber surrounded by another<br />

100- or 200-micron-thick layer of a harder plastic,<br />

such as Hytrelc. This may be removed with a razor<br />

blade. In order to prevent scratching of the fiber,<br />

the blade must be held at a very shallow angle with respect<br />

to the axis of the fiber. Furthermore, a blade<br />

should be used only once. After the jacket has been<br />

removed the fiber can be cleaved in any of several ways.<br />

One of these is shown in Fig. 3.6. Another technique<br />

consists of laying the fiber on a curved surface with<br />

approximately a 5 cm radius and applying a tension of<br />

about 1/4 pound (120 grams). The fiber is then scribed<br />

with a file causing a smooth cleave to occur. Another<br />

Fig. 3.7 A simple snug-fit connector with hole for<br />

index-matching fluid.<br />

index-matching fluid can squeeze out as the fiber ends<br />

are inserted. This is not an easily remountable type<br />

of connector. A fairly good splice can be formed in<br />

such a manner by using an index-matching epoxy in place<br />

of the index-matching liquid. If the splice is snug<br />

enough to hold the fiber fixed, an index-matching liquid<br />

can be used. The difficulty with such remountable connectors<br />

is that in order to be mounted and demounted<br />

many times it is necessary to maintain a radial clearance<br />

of at least several microns. This technique is<br />

not practical for singlemode fibers because no more<br />

than an 0.5 urn lateral displacement is allowed In order<br />

to avoid excesaive power losa.<br />

A connector, recently marketed by TRW Incorporated<br />

is shown in Fig. 3.8 (see Ref. 1 in Subsection<br />

3.1.1). Four relatively large diameter glass rods are