FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

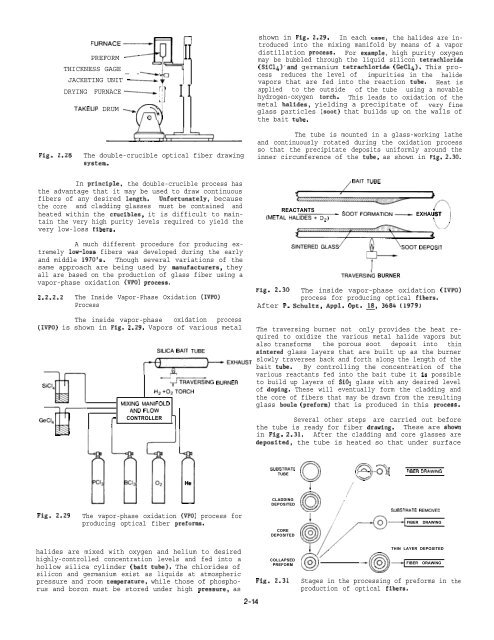

Fig. 2.28<br />

FURNACE—<br />

PREFORM —<br />

n<br />

II<br />

THICKNESS GAGE — - - -<br />

JACKETING UNIT z+<br />

P<br />

DRYING FURNACE —-----r!l II<br />

+<br />

TAKEUP DRUM -<br />

6)<br />

~> ‘<br />

The double-crucible optical fiber drawing<br />

system.<br />

In principle, the double-crucible process has<br />

the advantage that it may be used to draw continuous<br />

fibers of any desired length. Unfortunately, because<br />

the core and cladding glasses must be contained and<br />

heated within the crucibles, it is difficult to maintain<br />

the very high purity levels required to yield the<br />

very low-loss fibers.<br />

A much different procedure for producing extremely<br />

low-losa fibers was developed during the early<br />

and middle 1970’a. Though several variations of the<br />

same approach are being used by manufacturer, they<br />

all are based on the production of glass fiber using a<br />

vapor-phase oxidation (VPO) process.<br />

2.2.2.2 The Inside Vapor-Phase Oxidation (IVPO)<br />

Process<br />

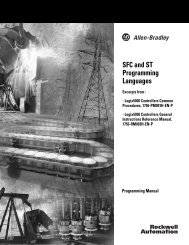

The inside vapor-phase oxidation process<br />

(IVPO) is shown in Fig. 2.29. Vapors of various metal<br />

SiCl 4<br />

J.<br />

GeC14<br />

Q<br />

r<br />

MIXING MANIFOLD<br />

AND FLOW<br />

CONTROLLER<br />

SILICA BAIT TUBE<br />

‘+== BURNER<br />

H2+02TORCH<br />

1<br />

shown in Fig. 2.29. In each case, the halides are introduced<br />

into the mixing manifold by means of a vapor<br />

distillation process. For example, high purity oxygen<br />

may be bubbled through the liquid silicon tetrachloride<br />

(SiC14)”and germanium tetrachloride (GeC14). This process<br />

reduces the level of impurities in the halide<br />

vapors that are fed into the reaction tube. Heat is<br />

applied to the outside of the tube using a movable<br />

hydrogen-oxygen torch. This leads to oxidation of the<br />

metal halides, yielding a precipitate of very fine<br />

glass particles (soot) that builds up on the walls of<br />

the bait tube.<br />

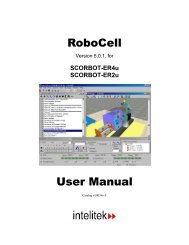

The tube is mounted in a glass-working lathe<br />

and continuously rotated during the oxidation process<br />

so that the precipitate deposits uniformly around the<br />

inner circumference of the tube, as shown in Fig. 2.30.<br />

BAIT TUBE<br />

/<br />

REACTANTS<br />

_ SOOT FORMATION_<br />

(METAL HALIDES+ 02)<br />

SINTERED GLASS<br />

TRAVERSINiG BURNER<br />

EXHAUST<br />

:)<br />

u’<br />

SOOT DEPOSIT<br />

Fig. 2.30 The inside vapor-phase oxidation (IVPO)<br />

process for producing optical fibers.<br />

After P. Schultz, Appl. Opt. Q, 3684 (1979)<br />

The traversing burner not only provides the heat required<br />

to oxidize the various metal halide vapors but<br />

also transforms the porous soot deposit into thin<br />

sintered glass layers that are built up as the burner<br />

slowly traverses back and forth along the length of the<br />

bait tube. By controlling the concentration of the<br />

various reactants fed into the bait tube it ia possible<br />

to build up layers of Si02 glass with any desired level<br />

of doping. These will eventually form the cladding and<br />

the core of fibers that may be drawn from the resulting<br />

glass boule (preform) that is produced in this process.<br />

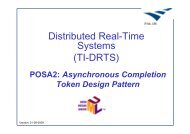

Several other steps are carried out before<br />

the tube is ready for fiber drawing. These are show<br />

in Fig. 2.31. After the cladding and core glasses are<br />

depoaited, the tube is heated so that under surface<br />

Fig. 2.29<br />

i)He<br />

The vapor-phase oxidation (VPO) process for<br />

producing optical fiber preforms.<br />

halides are mixed with oxygen and helium to desired<br />

highly-controlled concentration levels and fed into a<br />

hollow silica cylinder (bait tube). The chlorides of<br />

silicon and germanium exist as liquids at atmospheric<br />

pressure and room temperature, while those of phosphorus<br />

and boron must be stored under high pressure, as<br />

2-14<br />

SUSSTRATE<br />

TUBE<br />

CLADDING<br />

DEPOSITED<br />

CORE<br />

DEPOSITED<br />

COLLAPSED<br />

PREFORM<br />

Fig. 2.31<br />

c1 Q+ ,- d<br />

I<br />

/<br />

FIBER DRAWING<br />

‘1 ~ÿÿÿÿÿÿÿÿÿÿÿ<br />

@ /; SUBSTRATE REMOVED<br />

DRAWING<br />

gjjj/p”FIBER<br />

1// THIN LAYER DEPOSITED<br />

‘, //<br />

—u<br />

(3”<br />

oc’? FIBER ORAWING<br />

Stages in the processing of preforms in<br />

production of optical fibers.<br />

the