FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

left. The ends of the two fibers are brought together<br />

wittmut necessarily eliminating lateral displacement.<br />

Upon heating, the fiber melts and surface tensions tend<br />

to align the fibers as shown. The graph on the right<br />

side of Fig. 3.12 shows connector loss as a function<br />

of lateral displacement both before and after heating.<br />

The results prior to fusing is a theoretical curve with<br />

experimental reaults superimposed. As can be seen a<br />

significant reduction in loss is realized as a reault<br />

of fusion splicing.<br />

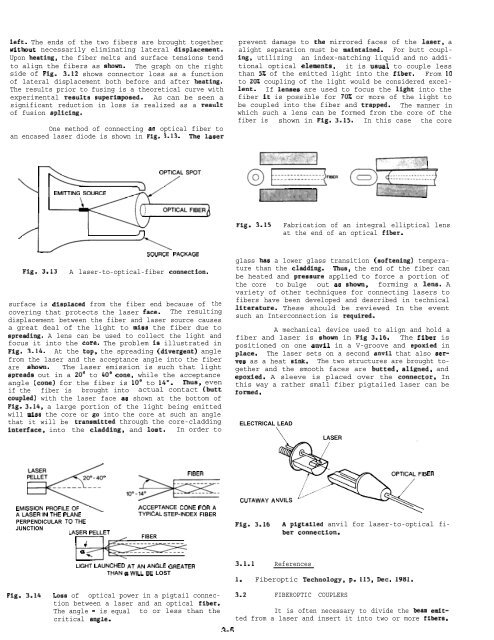

One method of connecting an optical fiber to<br />

an encased laser diode is shown in Fig. 3.13. The laser<br />

prevent damage to the mirrored faces of the laser, a<br />

alight separation must be maintained. For butt coupling,<br />

utilizing an index-matching liquid and no additional<br />

optical elementa, it is us~i to couple less<br />

than 5% of the emitted light into the fiber. From 10<br />

to 20% coupling of the light would be considered excellent.<br />

If lenaes are used to focus the light into the<br />

fiber it is possible for 70% or more of the light to<br />

be coupled into the fiber and trapped. The manner in<br />

which such a lens can be formed from the core of the<br />

fiber is shown in Fig. 3.15. In this case the core<br />

OPTICAL SPOT<br />

EMITTING SOURCE<br />

/ /1 I n<br />

Fig. 3.15<br />

Fabrication of an integral elliptical lens<br />

at the end of an optical fiber.<br />

Fig. 3.13<br />

SOURCE PACKAGE<br />

A laser-to-optical-fiber connection.<br />

surface is displaced from the fiber end because of the<br />

covering that protects the laser face. The resulting<br />

displacement between the fiber and laser source causes<br />

a great deal of the light to miss the fiber due to<br />

spreading. A lens can be used to collect the light and<br />

focus it into the core. The problem is illustrated in<br />

Fig. 3.14. At the top, the spreading (divergent) angle<br />

from the laser and the acceptance angle into the fiber<br />

are ahown. The laser emission is such that light<br />

apreads out in a 20° to 40° cone, while the acceptance<br />

angle (cone) for the fiber is 10° to 14”. Thus, even<br />

if the fiber is brought into actual contact (butt<br />

coupled) with the laser face aa shown at the bottom of<br />

Fig. 3.14, a large portion of the light being emitted<br />

will mlaa the core or go into the core at such an angle<br />

that it will be trans~tted through the core-cladding<br />

interface, into the cladding, and lost. In order to<br />

glass haa a lower glass transition (softening) temperature<br />

than the cladding. Thus, the end of the fiber can<br />

be heated and preasure applied to force a portion of<br />

the core to bulge out aa shown, forming a lens. A<br />

variety of other techniques for connecting lasers to<br />

fibers have been developed and described in technical<br />

literature. These should be reviewed In the event<br />

such an Interconnection is required.<br />

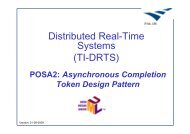

A mechanical device used to align and hold a<br />

fiber and laser is ahown in Fig 3.16. The fiber is<br />

positioned on one anvil in a V-groove and epoxied in<br />

place. The laser sets on a second anvil that also aerves<br />

as a heat aink. The two structures are brought together<br />

and the smooth faces are butted, aligned, and<br />

epoxied. A sleeve is placed over the connector. In<br />

this way a rather small fiber pigtailed laser can be<br />

formed.<br />

ELECTRICAL LEAD<br />

LASER<br />

@ ,oo--<br />

ER<br />

EMISSION PROFILEOF<br />

ALASERIN THE PLANE<br />

PERPENDICULAR TOTHE<br />

JUNCTION<br />

LASER PELLET<br />

+<br />

a.<br />

E:<br />

ACCEPTANCE CONE FORA<br />

TYPICAL STEP-INDEX FIBER<br />

FIBER<br />

LIGHT LAUNCHED ATAN ANGLE GREATER<br />

THANaWILLBE LOST<br />

CUTAWAYA<br />

Fig. 3.16<br />

3.1.1 References<br />

A pigtailed anvil for laser-to-optical<br />

ber connection.<br />

1. Fiberoptic Technology, p. 115, Dec. 1981.<br />

fi-<br />

Fig. 3.14<br />

Loas of optical power in a pigtail connection<br />

between a laser and an optical fiber.<br />

The angle = is equal to or less than the<br />

critical angle.<br />

2-5<br />

3.2 <strong>FIBEROPTIC</strong> COUPLERS<br />

It is often necessary to divide the beam emitted<br />

from a laser and insert it into two or more fibera.