FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

FIBEROPTIC SENSOR TECHNOLOGY HANDBOOK

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

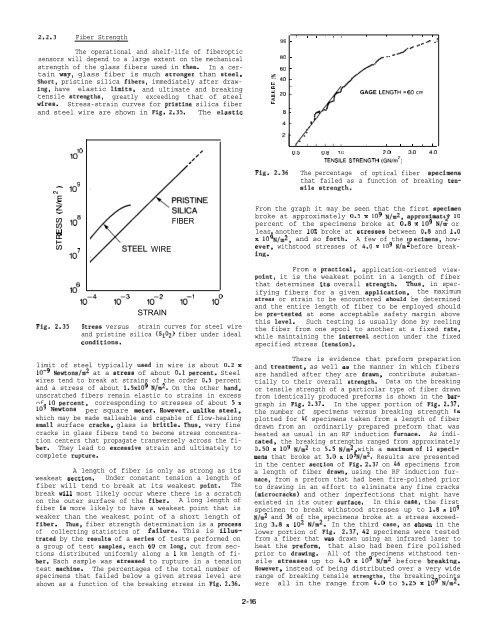

2.2.3 Fiber Strength<br />

The operational and shelf-life of fiberoptic<br />

sensors will depend to a large extent on the mechanical<br />

strength of the glass fibers used in them. In a certain<br />

way, glass fiber is much atronger than steel.<br />

Short, pristine silica fibers, immediately after drawing,<br />

have elastic limits, and ultimate and breaking<br />

tensile strengths, greatly exceeding that of steel<br />

wires. Stress-strain curves for priatine silica fiber<br />

and steel wire are shown in Fig. 2.35. The elaatic<br />

1 I I 1 ! , ( ! , , ,<br />

99 - *# .:<br />

80 -<br />

60 -<br />

./”<br />

./”””<br />

~ 40 - /<br />

u<br />

m<br />

3<br />

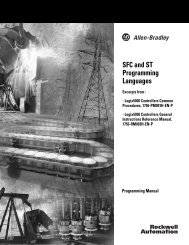

~ 20 GAGE LENGTH= 60cm<br />

if<br />

8 -<br />

4<br />

10’0<br />

- 109<br />

“E<br />

~<br />

$ 108<br />

w<br />

u<br />

G<br />

107<br />

106<br />

WIRE<br />

FIBER<br />

10–4 10–3 10–2 10–’ 10°<br />

STRAIN<br />

Fig. 2.35 Stresa versus strain curves for steel wire<br />

and pristine silica (Si02) fiber under ideal<br />

conditions.<br />

limit of steel typically uaed in wire is about 0.2 x<br />

10-9 Newtons/m2 at a atress of about 0.1 percent. Steel<br />

wires tend to break at strains of the order 0.5 percent<br />

and a stress of about 1.5x109 N/m2. On the other hand,<br />

unscratched fibers remain elastic to strains in excess<br />

of 10 percent, corresponding to stresses of about 5 x<br />

109 Newtona per square meter. However, unlike steel,<br />

which may be made malleable and capable of flow-healing<br />

small surface cracks, glass is brittle. Thus, very fine<br />

cracks in glass fibers tend to become stress concentration<br />

centers that propagate transversely across the fiber.<br />

They lead to exceasive strain and ultimately to<br />

complete rupture.<br />

A length of fiber is only as strong as its<br />

weakest section. Under constant tension a length of<br />

fiber will tend to break at its weakest point. The<br />

break will most likely occur where there is a scratch<br />

on the outer surface of the fiber. A long length of<br />

fiber ia more likely to have a weakest point that is<br />

weaker than the weakest point of a short length of<br />

fiber. Thus, fiber strength determination is a procesa<br />

of collecting statistics of failure. This is illustrated<br />

by the reaults of a seriea of tests performed on<br />

a group of test samples, each 60 cm long, cut from sections<br />

distributed uniformly along a 1 km length of fiber.<br />

Each sample was streased to rupture in a tension<br />

test machine. The percentages of the total number of<br />

specimens that failed below a given stress level are<br />

shown as a function of the breaking stress in Fig. 2.36.<br />

Fig.<br />

1 , I I , [<br />

0.5 0.8 10 2.0 3.0 4.0<br />

TENSILE STRENGTH (GN/m2)<br />

2.36 The percentage of optical fiber specimena<br />

that failed as a function of breaking tenaile<br />

strength.<br />

From the graph it may be seen that the first apecimen<br />

broke at approximately 0.5 x 109 N/m2, approximate 10<br />

percent of the specimens broke at 0.8 x 109 N/m J or<br />

leas another 10% broke at atresses between 0.8 and 1.0<br />

x 10 4N/m2, and so forth. A few of the s eclmens, however,<br />

withstood stresses of 4.0 x 109 N/m % before breaking.<br />

From a practical, application-oriented viewpoint,<br />

it is the weakest point in a length of fiber<br />

that determines ita overall strength. Thus, in specifying<br />

fibers for a given application, the maximum<br />

streas or strain to be encountered ahould be determined<br />

and the entire length of fiber to be employed should<br />

be pre-tested at some acceptable safety margin above<br />

this level. Such testing is usually done by reeling<br />

the fiber from one spool to another at a fixed rate,<br />

while maintaining the interreel section under the fixed<br />

specified stress (tension).<br />

There is evidence that preform preparation<br />

and treatment, as well aa the manner in which fibers<br />

are handled after they are drawn, contribute substantially<br />

to their overall atrength. Data on the breaking<br />

or tensile strength of a particular type of fiber drawn<br />

from identically produced preforms is shown in the bargraph<br />

in Fig. 2.37. In the upper portion of Fig. 2.37,<br />

the number of specimens versus breaking strength ia<br />

plotted for 40 specimens taken from a length of fiber<br />

drawn from an ordinarily prepared preform that was<br />

heated as usual in an RF induction furnace. As indicated,<br />

the breaking strengths ranged from approximately<br />

0.50 x 109 N/m2 to 5.5 N/m2 with a maximumof 12 specimena<br />

that broke at 3.0 x 10 4N/m2. Results are presented<br />

in the center aection of Fig. 2.37 on 46 specimens from<br />

a length of fiber drawn, using the RF induction furnace,<br />

from a preform that had been fire-polished prior<br />

to drawing in an effort to eliminate any fine cracks<br />

(microcracks) and other imperfections that might have<br />

existed in its outer surface. In this caae, the first<br />

specimen to break withstood stresses up to 1.8 x 109<br />

N/m2 and 36 of the specimens broke at a stress exceeding<br />

3.8 x 102 N/m2. In the third case, as ahown in the<br />

lower portion of Fig. 2.37, 42 specimens were tested<br />

from a fiber that waa drawn using an infrared laser to<br />

heat the preform, that also had been fire polished<br />

prior to drawing. All of the specimens withstood tensile<br />

atresses up to 4.0 x 109 N/m2 before breaking.<br />

However, instead of being distributed over a very wide<br />

range of breaking tensile strengths, the breaking points<br />

were all in the range from 4.0 to 5.25 x 109 N/m2.<br />

2-16