You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Back-To-Back Versus Face-To-Face Mountings<br />

Mountings having bearings applied in any of the face-to-face (DF)<br />

arrangements are objectionable because they provide the least<br />

rigidity. Furthermore, when the operating speeds are comparatively<br />

high, such mountings may buildup bearing preload excessively<br />

because of the temperature gradient between the housings,<br />

bearings and shafts. As this gradient increases, the bearing preload<br />

builds up, starting a detrimental cycle that may lead to premature<br />

spindle damage.<br />

In spindle mountings, the shaft temperature usually changes at<br />

a faster rate than the housing, creating temperature differentials<br />

between the two members. These are due to their difference in mass<br />

and their respective abilities to act as heat sinks. Thus, the shaft<br />

and the inner-ring spacer expand at a faster rate than the housing<br />

and the outer-ring spacer. As the shaft expands longitudinally and<br />

the inner-ring spacer lengthens, an axial load builds up on each<br />

bearing and continues to increase until the equilibrium temperature<br />

is reached. This occurs when the temperature at the housing levels<br />

off and the heat transferred from the bearings balances the heat<br />

generated within the system. There<strong>for</strong>e, if the housing attains an<br />

excessively high temperature, the initial bearing temperature is<br />

built up considerably.<br />

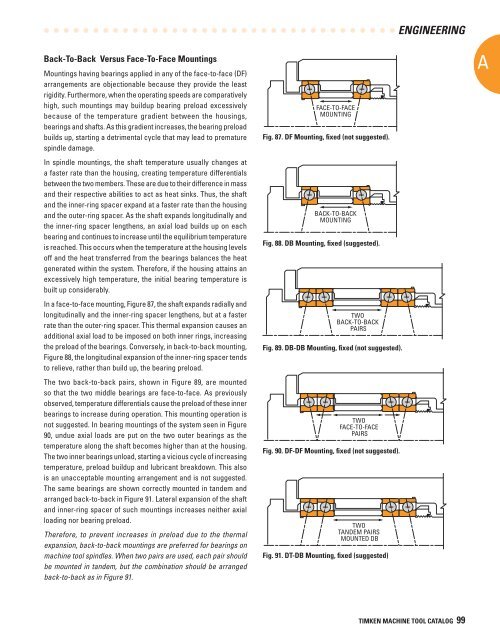

In a face-to-face mounting, Figure 87, the shaft expands radially and<br />

longitudinally and the inner-ring spacer lengthens, but at a faster<br />

rate than the outer-ring spacer. This thermal expansion causes an<br />

additional axial load to be imposed on both inner rings, increasing<br />

the preload of the bearings. Conversely, in back-to-back mounting,<br />

Figure 88, the longitudinal expansion of the inner-ring spacer tends<br />

to relieve, rather than build up, the bearing preload.<br />

The two back-to-back pairs, shown in Figure 89, are mounted<br />

so that the two middle bearings are face-to-face. As previously<br />

observed, temperature differentials cause the preload of these inner<br />

bearings to increase during operation. This mounting operation is<br />

not suggested. In bearing mountings of the system seen in Figure<br />

90, undue axial loads are put on the two outer bearings as the<br />

temperature along the shaft becomes higher than at the housing.<br />

The two inner bearings unload, starting a vicious cycle of increasing<br />

temperature, preload buildup and lubricant breakdown. This also<br />

is an unacceptable mounting arrangement and is not suggested.<br />

The same bearings are shown correctly mounted in tandem and<br />

arranged back-to-back in Figure 91. Lateral expansion of the shaft<br />

and inner-ring spacer of such mountings increases neither axial<br />

loading nor bearing preload.<br />

There<strong>for</strong>e, to prevent increases in preload due to the thermal<br />

expansion, back-to-back mountings are preferred <strong>for</strong> bearings on<br />

machine tool spindles. When two pairs are used, each pair should<br />

be mounted in tandem, but the combination should be arranged<br />

back-to-back as in Figure 91.<br />

FACE-TO-FACE<br />

MOUNTING<br />

Fig. 87. DF Mounting, fixed (not suggested).<br />

BACK-TO-BACK<br />

MOUNTING<br />

Fig. 88. DB Mounting, fixed (suggested).<br />

TWO<br />

BACK-TO-BACK<br />

PAIRS<br />

Fig. 89. DB-DB Mounting, fixed (not suggested).<br />

TWO<br />

FACE-TO-FACE<br />

PAIRS<br />

Fig. 90. DF-DF Mounting, fixed (not suggested).<br />

TWO<br />

TANDEM PAIRS<br />

MOUNTED DB<br />

Fig. 91. DT-DB Mounting, fixed (suggested)<br />

ENGINEERING<br />

A<br />

TIMKEN MACHINE TOOL CATALOG 99