You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Simple Mounting<br />

The evolution of two single-row bearing arrangements <strong>for</strong> spindles,<br />

discussed below, is directly related to the speed requirements and,<br />

consequently, the lubrication modes (see page 56).<br />

TS and TSF Arrangement<br />

The spindle is supported by one bearing at the nose position and a<br />

second one at the tail position. This layout offers the advantage of being<br />

a simple isostatic design that allows easy machining of adjacent parts.<br />

The mounting and setting procedures can be achieved without any<br />

specific tooling.<br />

Static stiffness calculations of the spindle-bearing system allow<br />

the optimum bearing spread to be determined precisely <strong>for</strong> each<br />

mounting, as a function of the overhung value of the spindle nose.<br />

A good approximation, however, is to consider that the distance<br />

between bearing centers should be of two and a half to three times<br />

ENGINEERING<br />

the spindle nose diameter. This represents an optimum value not<br />

only <strong>for</strong> stiffness, but also <strong>for</strong> thermal equilibrium.<br />

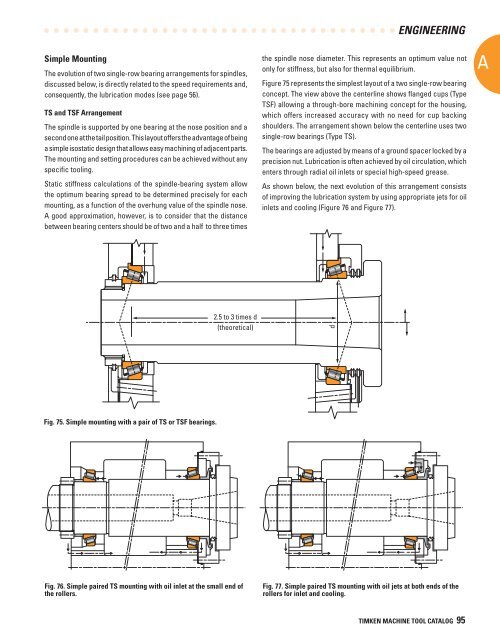

Figure 75 represents the simplest layout of a two single-row bearing<br />

concept. The view above the centerline shows flanged cups (Type<br />

TSF) allowing a through-bore machining concept <strong>for</strong> the housing,<br />

which offers increased accuracy with no need <strong>for</strong> cup backing<br />

shoulders. The arrangement shown below the centerline uses two<br />

single-row bearings (Type TS).<br />

The bearings are adjusted by means of a ground spacer locked by a<br />

precision nut. Lubrication is often achieved by oil circulation, which<br />

enters through radial oil inlets or special high-speed grease.<br />

As shown below, the next evolution of this arrangement consists<br />

of improving the lubrication system by using appropriate jets <strong>for</strong> oil<br />

inlets and cooling (Figure 76 and Figure 77).<br />

A<br />

2.5 to 3 times d<br />

(theoretical)<br />

d<br />

Fig. 75. Simple mounting with a pair of TS or TSF bearings.<br />

Fig. 76. Simple paired TS mounting with oil inlet at the small end of<br />

the rollers.<br />

Fig. 77. Simple paired TS mounting with oil jets at both ends of the<br />

rollers <strong>for</strong> inlet and cooling.<br />

TIMKEN MACHINE TOOL CATALOG 95