You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A<br />

ENGINEERING<br />

DUPLEX BALL BEARINGS<br />

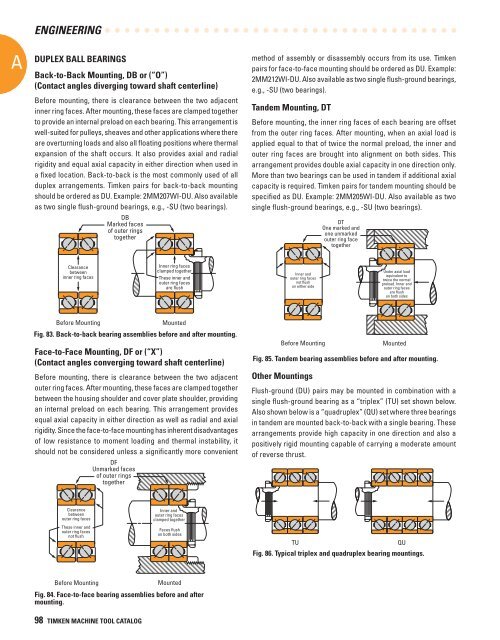

Back-to-Back Mounting, DB or (“O”)<br />

(Contact angles diverging toward shaft centerline)<br />

Be<strong>for</strong>e mounting, there is clearance between the two adjacent<br />

inner ring faces. After mounting, these faces are clamped together<br />

to provide an internal preload on each bearing. This arrangement is<br />

well-suited <strong>for</strong> pulleys, sheaves and other applications where there<br />

are overturning loads and also all floating positions where thermal<br />

expansion of the shaft occurs. It also provides axial and radial<br />

rigidity and equal axial capacity in either direction when used in<br />

a fixed location. Back-to-back is the most commonly used of all<br />

duplex arrangements. <strong>Timken</strong> pairs <strong>for</strong> back-to-back mounting<br />

should be ordered as DU. Example: 2MM207WI-DU. Also available<br />

as two single flush-ground bearings, e.g., -SU (two bearings).<br />

DB<br />

Marked faces<br />

of outer rings<br />

together<br />

method of assembly or disassembly occurs from its use. <strong>Timken</strong><br />

pairs <strong>for</strong> face-to-face mounting should be ordered as DU. Example:<br />

2MM212WI-DU. Also available as two single flush-ground bearings,<br />

e.g., -SU (two bearings).<br />

Tandem Mounting, DT<br />

Be<strong>for</strong>e mounting, the inner ring faces of each bearing are offset<br />

from the outer ring faces. After mounting, when an axial load is<br />

applied equal to that of twice the normal preload, the inner and<br />

outer ring faces are brought into alignment on both sides. This<br />

arrangement provides double axial capacity in one direction only.<br />

More than two bearings can be used in tandem if additional axial<br />

capacity is required. <strong>Timken</strong> pairs <strong>for</strong> tandem mounting should be<br />

specified as DU. Example: 2MM205WI-DU. Also available as two<br />

single flush-ground bearings, e.g., -SU (two bearings).<br />

DT<br />

One marked and<br />

one unmarked<br />

outer ring face<br />

together<br />

Clearance<br />

between<br />

inner ring faces<br />

Inner ring faces<br />

clamped together<br />

These inner and<br />

outer ring faces<br />

are flush<br />

Inner and<br />

outer ring faces<br />

not flush<br />

on either side<br />

Under axial load<br />

equivalent to<br />

twice the normal<br />

preload. Inner and<br />

outer ring faces<br />

are flush<br />

on both sides<br />

Be<strong>for</strong>e Mounting<br />

Mounted<br />

Fig. 83. Back-to-back bearing assemblies be<strong>for</strong>e and after mounting.<br />

Face-to-Face Mounting, DF or (“X”)<br />

(Contact angles converging toward shaft centerline)<br />

Be<strong>for</strong>e mounting, there is clearance between the two adjacent<br />

outer ring faces. After mounting, these faces are clamped together<br />

between the housing shoulder and cover plate shoulder, providing<br />

an internal preload on each bearing. This arrangement provides<br />

equal axial capacity in either direction as well as radial and axial<br />

rigidity. Since the face-to-face mounting has inherent disadvantages<br />

of low resistance to moment loading and thermal instability, it<br />

should not be considered unless a significantly more convenient<br />

DF<br />

Unmarked faces<br />

of outer rings<br />

together<br />

Be<strong>for</strong>e Mounting<br />

Mounted<br />

Fig. 85. Tandem bearing assemblies be<strong>for</strong>e and after mounting.<br />

Other Mountings<br />

Flush-ground (DU) pairs may be mounted in combination with a<br />

single flush-ground bearing as a “triplex” (TU) set shown below.<br />

Also shown below is a “quadruplex” (QU) set where three bearings<br />

in tandem are mounted back-to-back with a single bearing. These<br />

arrangements provide high capacity in one direction and also a<br />

positively rigid mounting capable of carrying a moderate amount<br />

of reverse thrust.<br />

Clearance<br />

between<br />

outer ring faces<br />

These inner and<br />

outer ring faces<br />

not flush<br />

Inner and<br />

outer ring faces<br />

clamped together<br />

Faces flush<br />

on both sides<br />

TU<br />

QU<br />

Fig. 86. Typical triplex and quadruplex bearing mountings.<br />

Be<strong>for</strong>e Mounting<br />

Mounted<br />

Fig. 84. Face-to-face bearing assemblies be<strong>for</strong>e and after<br />

mounting.<br />

98 TIMKEN MACHINE TOOL CATALOG