You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BALL BEARINGS<br />

Shaft Fits<br />

The main purpose of the shaft fit is to assure a proper attachment<br />

of the inner ring to the shaft. Under normal conditions of shaft<br />

rotation, a loosely fitted inner ring will creep on the shaft, leading<br />

to wear and fretting. This condition will be further aggravated by<br />

increase of load or speed. To prevent creeping or slipping, the<br />

inner ring should be mounted firmly in place and held securely<br />

against the shaft shoulder. However, it is important that the shaft<br />

fit should not result in any undue tightening of the bearing. An<br />

excessive interference fit of the bearing bore with the shaft could<br />

result in a proportionate expansion of the bearing inner ring which<br />

could disturb the internal fit of the bearing and lead to heating and<br />

increased power consumption.<br />

As a general rule, it is suggested that the shaft size and tolerance <strong>for</strong><br />

seating super precision ball bearings (ABEC 7/ISO P4 and ABEC 9/<br />

ISO P2) be the same as the bearing bore. In the case of<br />

preloaded bearings, the suggested shaft fit is line-to-line, since<br />

an excessively tight fit expands the bearing inner ring and<br />

increases the bearing preload, which can lead to overheating.<br />

For example, a duplex pair of 2MM9111WI DUL bearings with<br />

16 kg (35 lbs.) built-in preload, when mounted on a shaft that<br />

provides an interference fit of 0.010 mm (0.0004 in.), will increase<br />

the preload to approximately 86 kg (180 lbs.), which could result in<br />

elevated operating temperatures.<br />

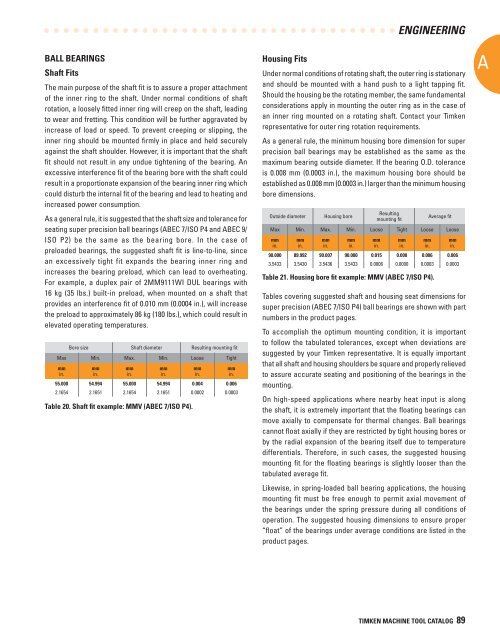

Bore size Shaft diameter Resulting mounting fit<br />

Max Min. Max. Min. Loose Tight<br />

mm<br />

in.<br />

mm<br />

in.<br />

mm<br />

in.<br />

55.000 54.994 55.000 54.994 0.004 0.006<br />

2.1654 2.1651 2.1654 2.1651 0.0002 0.0003<br />

mm<br />

in.<br />

Table 20. Shaft fit example: MMV (ABEC 7/ISO P4).<br />

mm<br />

in.<br />

mm<br />

in.<br />

Housing Fits<br />

ENGINEERING<br />

Under normal conditions of rotating shaft, the outer ring is stationary<br />

and should be mounted with a hand push to a light tapping fit.<br />

Should the housing be the rotating member, the same fundamental<br />

considerations apply in mounting the outer ring as in the case of<br />

an inner ring mounted on a rotating shaft. Contact your <strong>Timken</strong><br />

representative <strong>for</strong> outer ring rotation requirements.<br />

As a general rule, the minimum housing bore dimension <strong>for</strong> super<br />

precision ball bearings may be established as the same as the<br />

maximum bearing outside diameter. If the bearing O.D. tolerance<br />

is 0.008 mm (0.0003 in.), the maximum housing bore should be<br />

established as 0.008 mm (0.0003 in.) larger than the minimum housing<br />

bore dimensions.<br />

Resulting<br />

Outside diameter Housing bore<br />

Average fit<br />

mounting fit<br />

Max Min. Max. Min. Loose Tight Loose Loose<br />

mm<br />

in.<br />

mm<br />

in.<br />

mm<br />

in.<br />

mm<br />

in.<br />

90.000 89.992 90.007 90.000 0.015 0.000 0.006 0.006<br />

3.5433 3.5430 3.5436 3.5433 0.0006 0.0000 0.0003 0.0003<br />

Table 21. Housing bore fit example: MMV (ABEC 7/ISO P4).<br />

Tables covering suggested shaft and housing seat dimensions <strong>for</strong><br />

super precision (ABEC 7/ISO P4) ball bearings are shown with part<br />

numbers in the product pages.<br />

To accomplish the optimum mounting condition, it is important<br />

to follow the tabulated tolerances, except when deviations are<br />

suggested by your <strong>Timken</strong> representative. It is equally important<br />

that all shaft and housing shoulders be square and properly relieved<br />

to assure accurate seating and positioning of the bearings in the<br />

mounting.<br />

On high-speed applications where nearby heat input is along<br />

the shaft, it is extremely important that the floating bearings can<br />

move axially to compensate <strong>for</strong> thermal changes. Ball bearings<br />

cannot float axially if they are restricted by tight housing bores or<br />

by the radial expansion of the bearing itself due to temperature<br />

differentials. There<strong>for</strong>e, in such cases, the suggested housing<br />

mounting fit <strong>for</strong> the floating bearings is slightly looser than the<br />

tabulated average fit.<br />

Likewise, in spring-loaded ball bearing applications, the housing<br />

mounting fit must be free enough to permit axial movement of<br />

the bearings under the spring pressure during all conditions of<br />

operation. The suggested housing dimensions to ensure proper<br />

“float” of the bearings under average conditions are listed in the<br />

product pages.<br />

mm<br />

in.<br />

mm<br />

in.<br />

mm<br />

in.<br />

mm<br />

in.<br />

A<br />

TIMKEN MACHINE TOOL CATALOG 89