You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Lubrication Guidelines <strong>for</strong> Higher Speed <strong>Bearings</strong><br />

A precision tapered roller bearing can meet almost any level of<br />

speed required by the machine tool industry with the TSMA and<br />

Hydra-Rib high-speed bearing designs, providing circulating oil<br />

lubrication can be accommodated.<br />

Both the lubricant and lubrication system have an effect on heatgeneration<br />

and heat-dissipation rates and thus are important to the<br />

speed capabilities of a bearing.<br />

The choice of lubrication will depend on:<br />

• Maximum speed requirement.<br />

• Heat dissipation rate of the system.<br />

• Spindle layout.<br />

• Orientation of the spindle.<br />

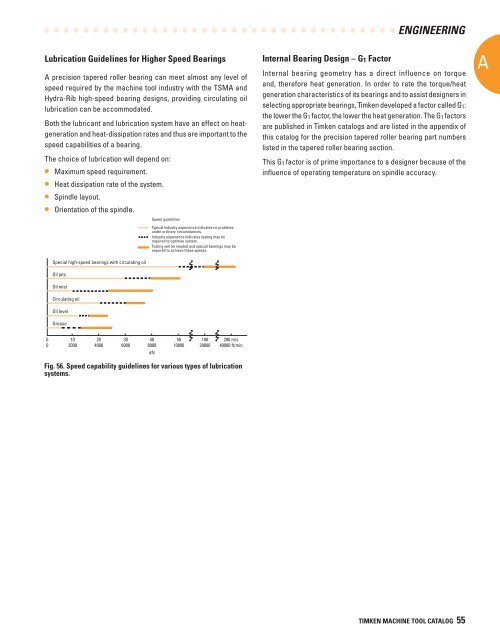

Special high-speed bearings with circulating oil<br />

Oil jets<br />

Oil mist<br />

Circulating oil<br />

Oil level<br />

Grease<br />

Speed guidelines<br />

Typical industry experience indicates no problems<br />

under ordinary circumstances.<br />

Industry experience indicates testing may be<br />

required to optimize system.<br />

Testing will be needed and special bearings may be<br />

required to achieve these speeds.<br />

Internal Bearing Design – G 1 Factor<br />

ENGINEERING<br />

Internal bearing geometry has a direct influence on torque<br />

and, there<strong>for</strong>e heat generation. In order to rate the torque/heat<br />

generation characteristics of its bearings and to assist designers in<br />

selecting appropriate bearings, <strong>Timken</strong> developed a factor called G 1:<br />

the lower the G 1 factor, the lower the heat generation. The G 1 factors<br />

are published in <strong>Timken</strong> catalogs and are listed in the appendix of<br />

this catalog <strong>for</strong> the precision tapered roller bearing part numbers<br />

listed in the tapered roller bearing section.<br />

This G 1 factor is of prime importance to a designer because of the<br />

influence of operating temperature on spindle accuracy.<br />

A<br />

0 10 20 30 40 50 100 200 m/s<br />

0 2000 4000 6000 8000 10000 20000 40000 ft/min<br />

dN<br />

Fig. 56. Speed capability guidelines <strong>for</strong> various types of lubrication<br />

systems.<br />

TIMKEN MACHINE TOOL CATALOG 55