You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A<br />

ENGINEERING<br />

SELECTING THE APPROPRIATE MACHINE<br />

TOOL BEARING<br />

PRECISION TAPERED ROLLER BEARINGS<br />

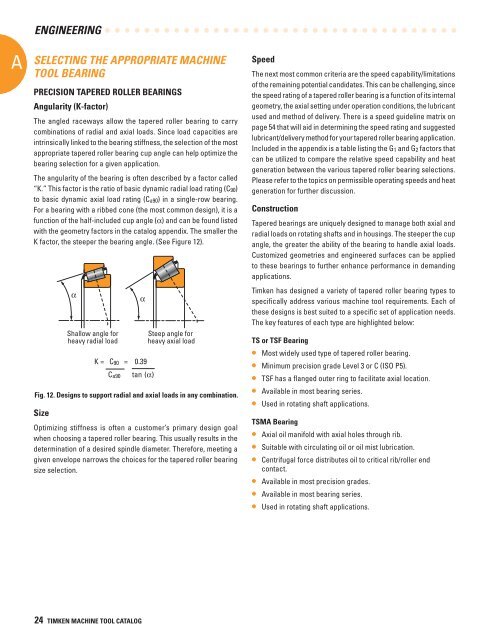

Angularity (K-factor)<br />

The angled raceways allow the tapered roller bearing to carry<br />

combinations of radial and axial loads. Since load capacities are<br />

intrinsically linked to the bearing stiffness, the selection of the most<br />

appropriate tapered roller bearing cup angle can help optimize the<br />

bearing selection <strong>for</strong> a given application.<br />

The angularity of the bearing is often described by a factor called<br />

“K.” This factor is the ratio of basic dynamic radial load rating (C 90)<br />

to basic dynamic axial load rating (C a90) in a single-row bearing.<br />

For a bearing with a ribbed cone (the most common design), it is a<br />

function of the half-included cup angle (α) and can be found listed<br />

with the geometry factors in the catalog appendix. The smaller the<br />

K factor, the steeper the bearing angle. (See Figure 12).<br />

Size<br />

<br />

Shallow angle <strong>for</strong><br />

heavy radial load<br />

K = C 90 = 0.39<br />

tan (α)<br />

C a90<br />

Fig. 12. Designs to support radial and axial loads in any combination.<br />

Optimizing stiffness is often a customer’s primary design goal<br />

when choosing a tapered roller bearing. This usually results in the<br />

determination of a desired spindle diameter. There<strong>for</strong>e, meeting a<br />

given envelope narrows the choices <strong>for</strong> the tapered roller bearing<br />

size selection.<br />

<br />

Steep angle <strong>for</strong><br />

heavy axial load<br />

Speed<br />

The next most common criteria are the speed capability/limitations<br />

of the remaining potential candidates. This can be challenging, since<br />

the speed rating of a tapered roller bearing is a function of its internal<br />

geometry, the axial setting under operation conditions, the lubricant<br />

used and method of delivery. There is a speed guideline matrix on<br />

page 54 that will aid in determining the speed rating and suggested<br />

lubricant/delivery method <strong>for</strong> your tapered roller bearing application.<br />

Included in the appendix is a table listing the G 1 and G 2 factors that<br />

can be utilized to compare the relative speed capability and heat<br />

generation between the various tapered roller bearing selections.<br />

Please refer to the topics on permissible operating speeds and heat<br />

generation <strong>for</strong> further discussion.<br />

Construction<br />

Tapered bearings are uniquely designed to manage both axial and<br />

radial loads on rotating shafts and in housings. The steeper the cup<br />

angle, the greater the ability of the bearing to handle axial loads.<br />

Customized geometries and engineered surfaces can be applied<br />

to these bearings to further enhance per<strong>for</strong>mance in demanding<br />

applications.<br />

<strong>Timken</strong> has designed a variety of tapered roller bearing types to<br />

specifically address various machine tool requirements. Each of<br />

these designs is best suited to a specific set of application needs.<br />

The key features of each type are highlighted below:<br />

TS or TSF Bearing<br />

• Most widely used type of tapered roller bearing.<br />

• Minimum precision grade Level 3 or C (ISO P5).<br />

• TSF has a flanged outer ring to facilitate axial location.<br />

• Available in most bearing series.<br />

• Used in rotating shaft applications.<br />

TSMA Bearing<br />

• Axial oil manifold with axial holes through rib.<br />

• Suitable with circulating oil or oil mist lubrication.<br />

• Centrifugal <strong>for</strong>ce distributes oil to critical rib/roller end<br />

contact.<br />

• Available in most precision grades.<br />

• Available in most bearing series.<br />

• Used in rotating shaft applications.<br />

24 TIMKEN MACHINE TOOL CATALOG