Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A<br />

ENGINEERING<br />

TIMKEN ® SUPER PRECISION BEARINGS<br />

Manufacturers require machine tools that are extremely accurate,<br />

reliable and capable of high levels of productivity. A major<br />

contribution to the per<strong>for</strong>mance of any machine tool is supplied by<br />

the rolling bearings used to support the spindles, rotating tables,<br />

ball screws and other critical precision positions. A manufactured<br />

bearing’s precision level has a major influence on the ability to<br />

per<strong>for</strong>m in high-speed applications commonly seen in factory<br />

machining environments.<br />

WHICH TYPE OF TIMKEN BEARING IS MOST<br />

APPROPRIATE FOR YOUR MACHINE TOOL<br />

APPLICATION?<br />

To achieve the highest possible per<strong>for</strong>mance precision level, the<br />

majority of machine tool-related bearing applications must address<br />

four primary requirements: speed, stiffness, accuracy and load<br />

capacity.<br />

Speed<br />

Today’s industrial machining environments stress maximum<br />

production rates. To reach these high metal-removal goals,<br />

machines are operating at maximum speeds with working spindles<br />

tuned to provide premium running accuracy.<br />

Achievable spindle rotating speeds require management of heat<br />

generation within the bearing assembly. The bearing’s ability to not<br />

only minimize heat buildup, but also expel excess heat, is a crucial<br />

consideration in the bearing selection process. Because of the<br />

differences in rolling element contact geometry, ball bearings are<br />

superior in minimizing heat generation, especially where higher<br />

speeds are desired.<br />

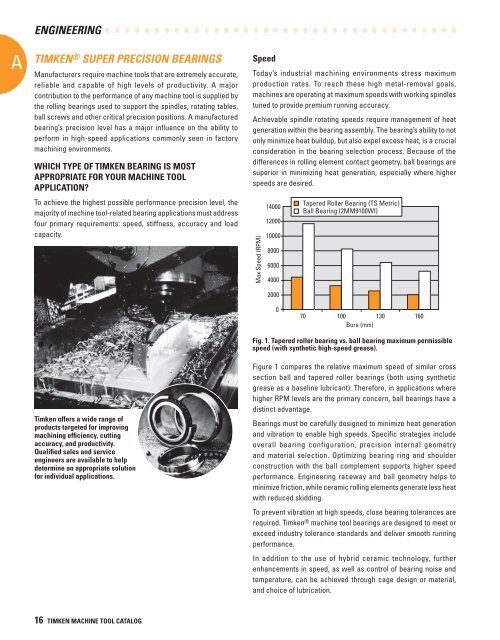

Max Speed (RPM)<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

4000<br />

2000<br />

Tapered Roller Bearing (TS Metric)<br />

Ball Bearing (2MM9100WI)<br />

0<br />

70 100 130 160<br />

Bore (mm)<br />

Fig. 1. Tapered roller bearing vs. ball bearing maximum permissible<br />

speed (with synthetic high-speed grease).<br />

<strong>Timken</strong> offers a wide range of<br />

products targeted <strong>for</strong> improving<br />

machining efficiency, cutting<br />

accuracy, and productivity.<br />

Qualified sales and service<br />

engineers are available to help<br />

determine an appropriate solution<br />

<strong>for</strong> individual applications.<br />

Figure 1 compares the relative maximum speed of similar cross<br />

section ball and tapered roller bearings (both using synthetic<br />

grease as a baseline lubricant). There<strong>for</strong>e, in applications where<br />

higher RPM levels are the primary concern, ball bearings have a<br />

distinct advantage.<br />

<strong>Bearings</strong> must be carefully designed to minimize heat generation<br />

and vibration to enable high speeds. Specific strategies include<br />

overall bearing configuration, precision internal geometry<br />

and material selection. Optimizing bearing ring and shoulder<br />

construction with the ball complement supports higher speed<br />

per<strong>for</strong>mance. Engineering raceway and ball geometry helps to<br />

minimize friction, while ceramic rolling elements generate less heat<br />

with reduced skidding.<br />

To prevent vibration at high speeds, close bearing tolerances are<br />

required. <strong>Timken</strong> ® machine tool bearings are designed to meet or<br />

exceed industry tolerance standards and deliver smooth running<br />

per<strong>for</strong>mance.<br />

In addition to the use of hybrid ceramic technology, further<br />

enhancements in speed, as well as control of bearing noise and<br />

temperature, can be achieved through cage design or material,<br />

and choice of lubrication.<br />

16 TIMKEN MACHINE TOOL CATALOG