Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

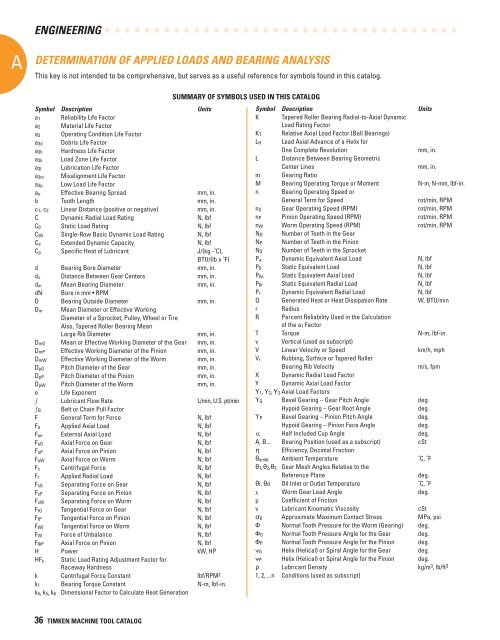

ENGINEERING<br />

A<br />

DETERMINATION OF APPLIED LOADS AND BEARING ANALYSIS<br />

This key is not intended to be comprehensive, but serves as a useful reference <strong>for</strong> symbols found in this catalog.<br />

Symbol Description Units<br />

a 1 Reliability Life Factor<br />

a 2 Material Life Factor<br />

a 3 Operating Condition Life Factor<br />

a 3d Debris Life Factor<br />

a 3h Hardness Life Factor<br />

a 3k Load Zone Life Factor<br />

a 3l Lubrication Life Factor<br />

a 3m Misalignment Life Factor<br />

a 3p Low Load Life Factor<br />

a e Effective Bearing Spread mm, in.<br />

b Tooth Length mm, in.<br />

c 1, c 2 Linear Distance (positive or negative) mm, in.<br />

C Dynamic Radial Load Rating N, lbf<br />

C 0 Static Load Rating N, lbf<br />

C 90 Single-Row Basic Dynamic Load Rating N, lbf<br />

C e Extended Dynamic Capacity N, lbf<br />

C p Specific Heat of Lubricant J/(kg -˚C),<br />

BTU/(lb x ˚F)<br />

d Bearing Bore Diameter mm, in.<br />

d c Distance Between Gear Centers mm, in.<br />

d m Mean Bearing Diameter mm, in.<br />

dN Bore in mm • RPM<br />

D Bearing Outside Diameter mm, in.<br />

D m Mean Diameter or Effective Working<br />

Diameter of a Sprocket, Pulley, Wheel or Tire<br />

Also, Tapered Roller Bearing Mean<br />

Large Rib Diameter<br />

mm, in.<br />

D mG Mean or Effective Working Diameter of the Gear mm, in.<br />

D mP Effective Working Diameter of the Pinion mm, in.<br />

D mW Effective Working Diameter of the Worm mm, in.<br />

D pG Pitch Diameter of the Gear mm, in.<br />

D pP Pitch Diameter of the Pinion mm, in.<br />

D pW Pitch Diameter of the Worm mm, in.<br />

e Life Exponent<br />

Lubricant Flow Rate<br />

L/min, U.S. pt/min<br />

B Belt or Chain Pull Factor<br />

F General Term <strong>for</strong> Force N, lbf<br />

F a Applied Axial Load N, lbf<br />

F ae External Axial Load N, lbf<br />

F aG Axial Force on Gear N, lbf<br />

F aP Axial Force on Pinion N, lbf<br />

F aW Axial Force on Worm N, lbf<br />

F c Centrifugal Force N, lbf<br />

F r Applied Radial Load N, lbf<br />

F sG Separating Force on Gear N, lbf<br />

F sP Separating Force on Pinion N, lbf<br />

F sW Separating Force on Worm N, lbf<br />

F tG Tangential Force on Gear N, lbf<br />

F tP Tangential Force on Pinion N, lbf<br />

F tW Tangential Force on Worm N, lbf<br />

F W Force of Unbalance N, lbf<br />

F P Axial Force on Pinion N, lbf<br />

H Power kW, HP<br />

HF s Static Load Rating Adjustment Factor <strong>for</strong><br />

Raceway Hardness<br />

k Centrifugal Force Constant lbf/RPM 2<br />

k 1 Bearing Torque Constant N-m, lbf-in.<br />

k 4, k 5, k 6 Dimensional Factor to Calculate Heat Generation<br />

SUMMARY OF SYMBOLS USED IN THIS CATALOG<br />

Symbol Description Units<br />

K Tapered Roller Bearing Radial-to-Axial Dynamic<br />

Load Rating Factor<br />

K T Relative Axial Load Factor (Ball <strong>Bearings</strong>)<br />

L H Lead Axial Advance of a Helix <strong>for</strong><br />

One Complete Revolution<br />

mm, in.<br />

L Distance Between Bearing Geometric<br />

Center Lines<br />

mm, in.<br />

m Gearing Ratio<br />

M Bearing Operating Torque or Moment N-m, N-mm, lbf-in.<br />

n Bearing Operating Speed or<br />

General Term <strong>for</strong> Speed<br />

rot/min, RPM<br />

n G Gear Operating Speed (RPM) rot/min, RPM<br />

n P Pinion Operating Speed (RPM) rot/min, RPM<br />

n W Worm Operating Speed (RPM) rot/min, RPM<br />

N G Number of Teeth in the Gear<br />

N P Number of Teeth in the Pinion<br />

N S Number of Teeth in the Sprocket<br />

P a Dynamic Equivalent Axial Load N, lbf<br />

P 0 Static Equivalent Load N, lbf<br />

P 0a Static Equivalent Axial Load N, lbf<br />

P 0r Static Equivalent Radial Load N, lbf<br />

P r Dynamic Equivalent Radial Load N, lbf<br />

Q Generated Heat or Heat Dissipation Rate W, BTU/min<br />

r Radius<br />

R Percent Reliability Used in the Calculation<br />

of the a 1 Factor<br />

T Torque N-m, lbf-in.<br />

v Vertical (used as subscript)<br />

V Linear Velocity or Speed km/h, mph<br />

V r Rubbing, Surface or Tapered Roller<br />

Bearing Rib Velocity<br />

m/s, fpm<br />

X Dynamic Radial Load Factor<br />

Y Dynamic Axial Load Factor<br />

Y 1, Y 2, Y 3 Axial Load Factors<br />

G Bevel Gearing – Gear Pitch Angle deg.<br />

Hypoid Gearing – Gear Root Angle<br />

deg.<br />

P Bevel Gearing – Pinion Pitch Angle deg.<br />

Hypoid Gearing – Pinion Face Angle<br />

deg.<br />

Half Included Cup Angle<br />

deg.<br />

A, B... Bearing Position (used as a subscript) cSt<br />

Efficiency, Decimal Fraction<br />

ambt Ambient Temperature ˚C, ˚F<br />

1, 2, 3 Gear Mesh Angles Relative to the<br />

Reference Plane<br />

deg.<br />

i, o Oil Inlet or Outlet Temperature ˚C, ˚F<br />

Worm Gear Lead Angle deg.<br />

μ Coefficient of Friction<br />

v Lubricant Kinematic Viscosity cSt<br />

0 Approximate Maximum Contact Stress MPa, psi<br />

Normal Tooth Pressure <strong>for</strong> the Worm (Gearing) deg.<br />

G Normal Tooth Pressure Angle <strong>for</strong> the Gear deg.<br />

P Normal Tooth Pressure Angle <strong>for</strong> the Pinion deg.<br />

G Helix (Helical) or Spiral Angle <strong>for</strong> the Gear deg.<br />

P Helix (Helical) or Spiral Angle <strong>for</strong> the Pinion deg.<br />

Lubricant Density kg/m 3 , lb/ft 3<br />

1, 2, ...n Conditions (used as subscript)<br />

36 TIMKEN MACHINE TOOL CATALOG