Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A<br />

ENGINEERING<br />

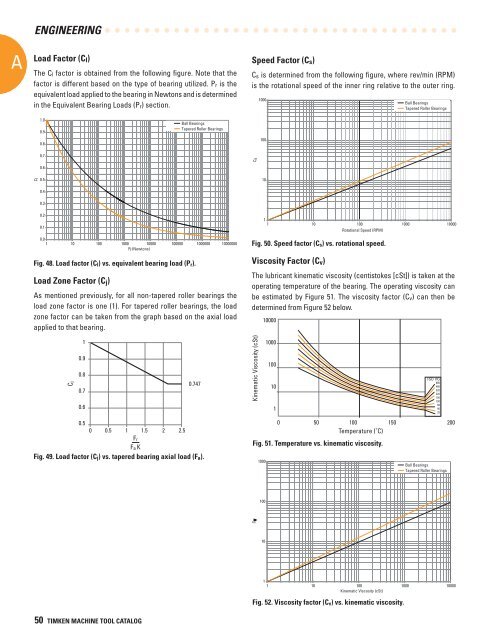

Load Factor (C l )<br />

The C l factor is obtained from the following figure. Note that the<br />

factor is different based on the type of bearing utilized. P r is the<br />

equivalent load applied to the bearing in Newtons and is determined<br />

in the Equivalent Bearing Loads (P r) section.<br />

Speed Factor (C s )<br />

C s is determined from the following figure, where rev/min (RPM)<br />

is the rotational speed of the inner ring relative to the outer ring.<br />

1000<br />

Ball <strong>Bearings</strong><br />

Tapered Roller <strong>Bearings</strong><br />

1.0<br />

0.9<br />

0.8<br />

Ball <strong>Bearings</strong><br />

Tapered Roller <strong>Bearings</strong><br />

100<br />

0.7<br />

Cs<br />

0.6<br />

Cl<br />

0.5<br />

10<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

1 10 100 1000 10000 100000 1000000 10000000<br />

Pr (Newtons)<br />

Fig. 48. Load factor (C l) vs. equivalent bearing load (P r).<br />

Load Zone Factor (C j )<br />

As mentioned previously, <strong>for</strong> all non-tapered roller bearings the<br />

load zone factor is one (1). For tapered roller bearings, the load<br />

zone factor can be taken from the graph based on the axial load<br />

applied to that bearing.<br />

1<br />

1 10 100 1000 10000<br />

Rotational Speed (RPM)<br />

Fig. 50. Speed factor (C s) vs. rotational speed.<br />

Viscosity Factor (C v )<br />

The lubricant kinematic viscosity (centistokes [cSt]) is taken at the<br />

operating temperature of the bearing. The operating viscosity can<br />

be estimated by Figure 51. The viscosity factor (C v) can then be<br />

determined from Figure 52 below.<br />

10000<br />

Cj<br />

1<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.747<br />

Kinematic Viscosity (cSt)<br />

1000<br />

100<br />

10<br />

1<br />

ISO VG<br />

680<br />

460<br />

320<br />

220<br />

150<br />

100<br />

68<br />

46<br />

32<br />

0.5<br />

0 0.5 1 1.5 2 2.5<br />

F r<br />

F a K<br />

Fig. 49. Load factor (C j) vs. tapered bearing axial load (F a).<br />

0 50 100 150 200<br />

Temperature (˚C)<br />

Fig. 51. Temperature vs. kinematic viscosity.<br />

1000<br />

Ball <strong>Bearings</strong><br />

Tapered Roller <strong>Bearings</strong><br />

100<br />

Cv<br />

10<br />

1<br />

1 10 100 1000 10000<br />

Kinematic Viscosity (cSt)<br />

Fig. 52. Viscosity factor (C v) vs. kinematic viscosity.<br />

50 TIMKEN MACHINE TOOL CATALOG