- Page 1 and 2:

Timken ® Super Precision Bearings

- Page 3 and 4:

TIMKEN MACHINE TOOL CATALOG TIMKEN.

- Page 5 and 6:

TIMKEN MACHINE TOOL CATALOG BRANDS

- Page 7 and 8:

TIMKEN MACHINE TOOL CATALOG The Qui

- Page 9 and 10:

TIMKEN MACHINE TOOL CATALOG 2 2 2 L

- Page 11 and 12:

TIMKEN MACHINE TOOL CATALOG Inasmuc

- Page 13 and 14:

A ENGINEERING A 12 TIMKEN MACHINE T

- Page 15 and 16:

ENGINEERING A Typical consideration

- Page 17 and 18:

A ENGINEERING TIMKEN ® SUPER PRECI

- Page 19 and 20:

A ENGINEERING Stiffness (relative t

- Page 21 and 22:

A ENGINEERING Load Capacity Some ma

- Page 23 and 24:

A ENGINEERING Precision Tapered Rol

- Page 25 and 26:

A ENGINEERING SELECTING THE APPROPR

- Page 27 and 28:

A ENGINEERING SUPER PRECISION BALL

- Page 29 and 30:

A ENGINEERING High Contact Angle (2

- Page 31 and 32:

A ENGINEERING Timken super precisio

- Page 33 and 34:

A ENGINEERING The overhung distance

- Page 35 and 36:

A ENGINEERING The unique design of

- Page 37 and 38:

ENGINEERING A DETERMINATION OF APPL

- Page 39 and 40:

ENGINEERING A Straight Bevel Gear T

- Page 41 and 42:

A ENGINEERING Worm Gear Tangential

- Page 43 and 44:

A ENGINEERING BEARING REACTIONS Cal

- Page 45 and 46:

ENGINEERING A FrA Bearing A Fae Bea

- Page 47 and 48:

A ENGINEERING ALTERNATE APPROACH FO

- Page 49 and 50:

A ENGINEERING Reliability Life Fact

- Page 51 and 52: A ENGINEERING Load Factor (C l ) Th

- Page 53 and 54: A ENGINEERING SYSTEM LIFE AND WEIGH

- Page 55 and 56: A ENGINEERING SPEED GUIDELINES FOR

- Page 57 and 58: ENGINEERING A LUBRICATION TAPERED R

- Page 59 and 60: A ENGINEERING BALL BEARINGS Even th

- Page 61 and 62: A ENGINEERING OIL Although several

- Page 63 and 64: A ENGINEERING BALL BEARINGS WITH GR

- Page 65 and 66: ENGINEERING A HEAT GENERATION AND D

- Page 67 and 68: A ENGINEERING BALL BEARINGS Heat Ge

- Page 69 and 70: ENGINEERING A TOLERANCES - continue

- Page 71 and 72: ENGINEERING A METRIC SYSTEM BEARING

- Page 73 and 74: ENGINEERING A TOLERANCES - continue

- Page 75 and 76: ENGINEERING A TOLERANCES - continue

- Page 77 and 78: ENGINEERING A TOLERANCES - continue

- Page 79 and 80: ENGINEERING A TOLERANCES - continue

- Page 81 and 82: A ENGINEERING FITTING PRACTICES GEN

- Page 83 and 84: ENGINEERING A PRECISION CLASS TAPER

- Page 85 and 86: ENGINEERING A PRECISION CLASS TAPER

- Page 87 and 88: ENGINEERING A PRECISION CLASS TAPER

- Page 89 and 90: A ENGINEERING SHAFT AND HOUSING CON

- Page 91 and 92: ENGINEERING A SHAFT AND HOUSING TOL

- Page 93 and 94: A ENGINEERING MOUNTING DESIGNS Obta

- Page 95 and 96: A ENGINEERING TAPERED ROLLER BEARIN

- Page 97 and 98: ENGINEERING A Fig. 78. Two designs

- Page 99 and 100: A ENGINEERING DUPLEX BALL BEARINGS

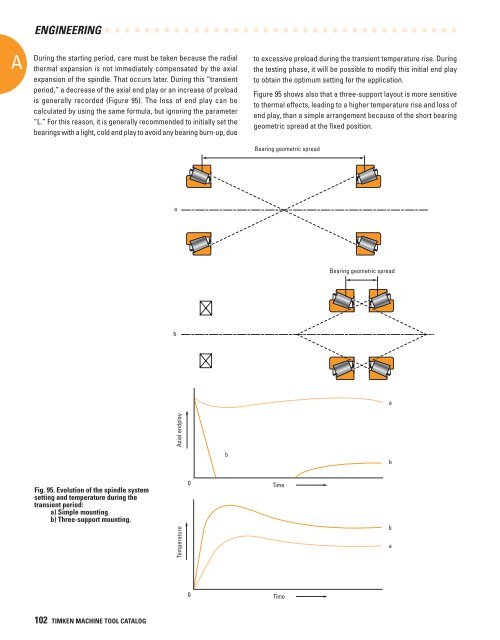

- Page 101: A ENGINEERING Spring-Loaded Mountin

- Page 105 and 106: ENGINEERING A NOTES 104 TIMKEN MACH

- Page 107 and 108: B Precision Tapered Roller Bearings

- Page 109 and 110: SUPER PRECISION B ASSEMBLY CODES

- Page 111 and 112: SUPER PRECISION B INTRODUCTION Timk

- Page 113 and 114: SUPER PRECISION TS STYLE PRECISION

- Page 115 and 116: SUPER PRECISION TS STYLE PRECISION

- Page 117 and 118: SUPER PRECISION B TSF STYLE PRECISI

- Page 119 and 120: SUPER PRECISION B TSF STYLE PRECISI

- Page 121 and 122: SUPER PRECISION TXR STYLE METRIC PR

- Page 123 and 124: SUPER PRECISION TSHR STYLE HYDRA-RI

- Page 125 and 126: SUPER PRECISION TSHR STYLE - contin

- Page 127 and 128: SUPER PRECISION TAPERED ROLLER BEAR

- Page 129 and 130: SUPER PRECISION 2 C A BALL BEARINGS

- Page 131 and 132: SUPER PRECISION C Super Precision B

- Page 133 and 134: C Super Precision Ball Bearings Bal

- Page 135 and 136: SUPER PRECISION 2 C A INTRODUCTION

- Page 137 and 138: SUPER PRECISION 2 C MICRON BORE AND

- Page 139 and 140: SUPER PRECISION 2 C A Ultra-Precisi

- Page 141 and 142: SUPER PRECISION 2 Single-Bar Machin

- Page 143 and 144: SUPER PRECISION 2 ULTRA-LIGHT ISO 1

- Page 145 and 146: SUPER PRECISION ULTRA-LIGHT ISO 19

- Page 147 and 148: SUPER PRECISION 2 C A ULTRA-LIGHT 2

- Page 149 and 150: SUPER PRECISION 2 ULTRA-LIGHT 2MM93

- Page 151 and 152: SUPER PRECISION ULTRA-LIGHT ISO 19

- Page 153 and 154:

SUPER PRECISION ULTRA-LIGHT ISO 19

- Page 155 and 156:

SUPER PRECISION 2 C A ULTRA-LIGHT 2

- Page 157 and 158:

SUPER PRECISION 2 ULTRA-LIGHT 2MMV9

- Page 159 and 160:

SUPER PRECISION EXTRA-LIGHT ISO 10

- Page 161 and 162:

SUPER PRECISION EXTRA-LIGHT ISO 10

- Page 163 and 164:

SUPER PRECISION 2 C A EXTRA-LIGHT 2

- Page 165 and 166:

SUPER PRECISION 2 EXTRA-LIGHT 2MM91

- Page 167 and 168:

SUPER PRECISION EXTRA-LIGHT ISO 10

- Page 169 and 170:

SUPER PRECISION EXTRA-LIGHT ISO 10

- Page 171 and 172:

SUPER PRECISION 2 C A EXTRA-LIGHT 2

- Page 173 and 174:

SUPER PRECISION EXTRA-LIGHT 2MMV910

- Page 175 and 176:

SUPER PRECISION EXTRA-LIGHT ISO 10

- Page 177 and 178:

SUPER PRECISION 2 EXTRA-LIGHT ISO 1

- Page 179 and 180:

SUPER PRECISION 2 C A EXTRA-LIGHT 2

- Page 181 and 182:

SUPER PRECISION 2 EXTRA-LIGHT 2MMV9

- Page 183 and 184:

SUPER PRECISION 2 ULTRA-LIGHT ISO 1

- Page 185 and 186:

SUPER PRECISION LIGHT ISO 02 SERIES

- Page 187 and 188:

SUPER PRECISION LIGHT ISO 02 SERIES

- Page 189 and 190:

SUPER PRECISION 2 C A LIGHT 2MM200W

- Page 191 and 192:

SUPER PRECISION LIGHT 2MM200WI ISO

- Page 193 and 194:

SUPER PRECISION LIGHT ISO 02 SERIES

- Page 195 and 196:

SUPER PRECISION MEDIUM ISO 03 SERIE

- Page 197 and 198:

2 C A SUPER PRECISION MEDIUM 2(3)MM

- Page 199 and 200:

SUPER PRECISION MEDIUM ISO 03 SERIE

- Page 201 and 202:

SUPER PRECISION 2 C BALL SCREW SUPP

- Page 203 and 204:

SUPER PRECISION 2 C BALL SCREW SUPP

- Page 205 and 206:

SUPER PRECISION 2 C BALL SCREW SUPP

- Page 207 and 208:

SUPER PRECISION 2 C BALL SCREW SUPP

- Page 209 and 210:

SUPER PRECISION 2 C BALL SCREW SUPP

- Page 211 and 212:

SUPER PRECISION 2 C BALL SCREW SUPP

- Page 213 and 214:

SUPER PRECISION 2 C BALL SCREW SUPP

- Page 215 and 216:

SUPER PRECISION 2 EX-CELL-O SPINDLE

- Page 217 and 218:

SUPER PRECISION BALL BEARING BORE D

- Page 219 and 220:

SUPER PRECISION D FREQUENCY COEFFIC

- Page 221 and 222:

SUPER PRECISION TSF Metric Style FT

- Page 223 and 224:

SUPER PRECISION FREQUENCY COEFFICIE

- Page 225 and 226:

SUPER PRECISION 2MMV9300HX Series F

- Page 227 and 228:

SUPER PRECISION 2MM9100WI Series FT

- Page 229 and 230:

SUPER PRECISION 2MMV9100HX Series F

- Page 231 and 232:

SUPER PRECISION 2MMV99100WN Series

- Page 233 and 234:

SUPER PRECISION 2MM200WI Series FTF

- Page 235 and 236:

SUPER PRECISION 2MM300WI Series FTF

- Page 237 and 238:

SUPER PRECISION FREQUENCY COEFFICIE

- Page 239 and 240:

SUPER PRECISION INCH SYSTEM Class D

- Page 241 and 242:

SUPER PRECISION GEOMETRY FACTORS -

- Page 243 and 244:

SUPER PRECISION BEARING LOCKNUTS To

- Page 245 and 246:

SUPER PRECISION LUBRICATION SPECIFI

- Page 247 and 248:

SUPER PRECISION D A CONVERSION TABL

- Page 249 and 250:

SUPER PRECISION Application Informa

- Page 251 and 252:

SUPER PRECISION INDEX ITEM PRODUCT

- Page 253 and 254:

SUPER PRECISION NOTES D A 252 TIMKE

- Page 255 and 256:

SUPER PRECISION NOTES D A 254 TIMKE

- Page 257 and 258:

SUPER PRECISION NOTES D A 256 TIMKE

- Page 259:

SUPER PRECISION NOTES D A 258 TIMKE