You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BALL BEARINGS<br />

Preloading of precision ball bearings to a predetermined axial load<br />

<strong>for</strong> “universal” mounting is accomplished by grinding a certain<br />

amount of stock off faces of the inner and outer rings so that be<strong>for</strong>e<br />

mounting the bearing, faces on the abutting side are offset an<br />

amount equal to the deflection under “preload.” When mounted,<br />

these faces are clamped together, the opposite bearing faces<br />

become flush and the bearing parts are subjected to compressive<br />

<strong>for</strong>ces, bringing the balls into contact with their respective raceways<br />

to take up the initial clearances of the bearings. Thus, the preload<br />

built into the bearings is automatically obtained. The condition of a<br />

preloaded ball bearing is similar to that of one in operation under<br />

axial load. This initial axial load serves to decrease the axial and<br />

radial deflections when subsequent operational loads are imposed<br />

on the bearing assembly.<br />

<strong>Bearings</strong> are preloaded no more than necessary. Excessive preload<br />

adds little to the rigidity of the spindle, but appreciably reduces the<br />

range of operating speeds by causing bearings to run hot at higher<br />

speeds. To meet conditions of speed, mounting arrangement and<br />

maximum rigidity consistent with low operating temperatures,<br />

<strong>Timken</strong> precision ball bearings are designed and produced with<br />

preloads varying from light to heavy and, in some instances, with<br />

negative preload.<br />

In many cases, the amount of bearing preload is a trade-off between<br />

having the desired degree of rigidity and reducing any adverse effect<br />

preloading has on the equipment. If the operating speed is high, a<br />

heavy preload can lead to excessively high operating temperatures,<br />

resulting in shortened bearing life. For these reasons, three classes<br />

of ball bearing preloads are most commonly used – light, medium and<br />

heavy. In certain applications, such as high-speed motorized router<br />

spindles, specially preloaded, super precision ball bearings are<br />

required. Such bearings are “zero” preloaded – that is, the faces of<br />

the inner and outer rings are ground flush under negligible load.<br />

The light, medium and heavy standard preload values <strong>for</strong> <strong>Timken</strong><br />

super precision angular contact ball bearings and <strong>for</strong> both high<br />

and low contact angles are located with the dimension tables in<br />

Section C.<br />

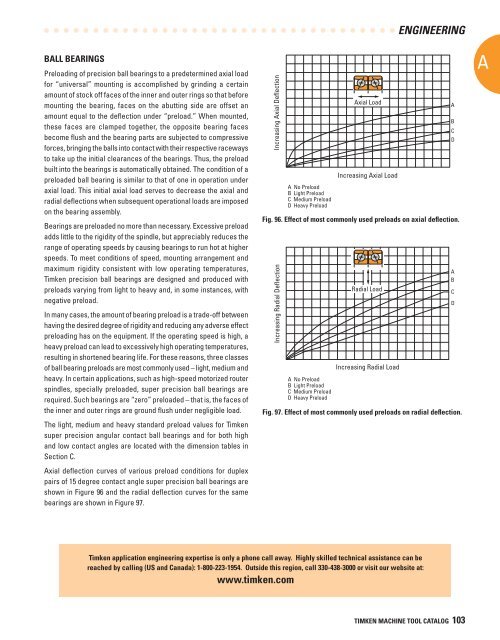

Axial deflection curves of various preload conditions <strong>for</strong> duplex<br />

pairs of 15 degree contact angle super precision ball bearings are<br />

shown in Figure 96 and the radial deflection curves <strong>for</strong> the same<br />

bearings are shown in Figure 97.<br />

Increasing Axial Deflection<br />

Increasing Radial Deflection<br />

A No Preload<br />

B Light Preload<br />

C Medium Preload<br />

D Heavy Preload<br />

Axial Load<br />

Increasing Axial Load<br />

ENGINEERING<br />

Fig. 96. Effect of most commonly used preloads on axial deflection.<br />

Radial Load<br />

Increasing Radial Load<br />

A No Preload<br />

B Light Preload<br />

C Medium Preload<br />

D Heavy Preload<br />

Fig. 97. Effect of most commonly used preloads on radial deflection.<br />

A<br />

B<br />

C<br />

D<br />

A<br />

B<br />

C<br />

D<br />

A<br />

<strong>Timken</strong> application engineering expertise is only a phone call away. Highly skilled technical assistance can be<br />

reached by calling (US and Canada): 1-800-223-1954. Outside this region, call 330-438-3000 or visit our website at:<br />

www.timken.com<br />

TIMKEN MACHINE TOOL CATALOG 103