You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ENGINEERING<br />

Grease Lubrication Factor (C gr )<br />

For grease lubrication, the EHL lubrication film becomes depleted of<br />

oil over time and is reduced in thickness. Consequently, a reduction<br />

factor (C gr) should be used to adjust <strong>for</strong> this effect.<br />

C gr = 0.79<br />

Misalignment Life Factor (a 3m )<br />

The life of the bearing depends on the magnitude of the angle of<br />

misalignment, on the internal bearing geometry, and on the applied<br />

loads.<br />

Accurate alignment of the shaft relative to the housing is critical <strong>for</strong><br />

best per<strong>for</strong>mance. The life prediction using the method defined in<br />

this publication is relatively accurate up to the limits listed within,<br />

based on bearing type. The base condition, <strong>for</strong> which the load rating<br />

of the roller bearing is defined, is 0.0005 radians misalignment.<br />

Per<strong>for</strong>mance of all <strong>Timken</strong> bearings under various levels of<br />

misalignment and radial and axial load can be predicted using<br />

sophisticated computer programs. Using these programs,<br />

<strong>Timken</strong> engineers can design special bearing-contact profiles<br />

to accommodate the conditions of radial load, axial load and/or<br />

bearing misalignment in your application. Consult your <strong>Timken</strong><br />

representative <strong>for</strong> more in<strong>for</strong>mation.<br />

a3p<br />

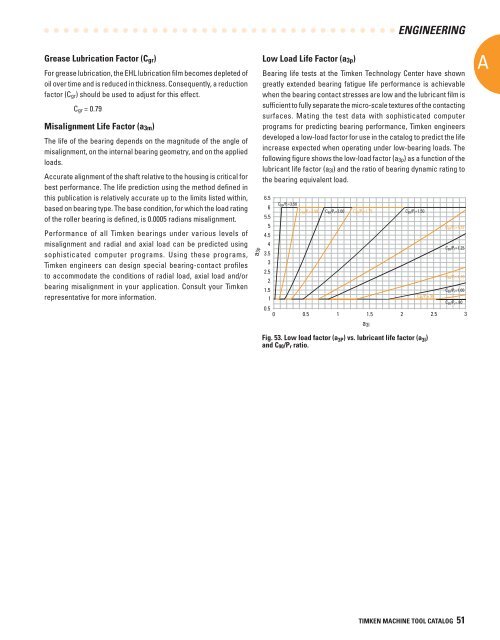

Low Load Life Factor (a 3p )<br />

Bearing life tests at the <strong>Timken</strong> Technology Center have shown<br />

greatly extended bearing fatigue life per<strong>for</strong>mance is achievable<br />

when the bearing contact stresses are low and the lubricant film is<br />

sufficient to fully separate the micro-scale textures of the contacting<br />

surfaces. Mating the test data with sophisticated computer<br />

programs <strong>for</strong> predicting bearing per<strong>for</strong>mance, <strong>Timken</strong> engineers<br />

developed a low-load factor <strong>for</strong> use in the catalog to predict the life<br />

increase expected when operating under low-bearing loads. The<br />

following figure shows the low-load factor (a 3p) as a function of the<br />

lubricant life factor (a 3l) and the ratio of bearing dynamic rating to<br />

the bearing equivalent load.<br />

6.5<br />

C 90 /P r =3.50<br />

6<br />

C 90 /P r =2.50 C 90 /P r =2.00 C90/P r =1.75 C 90 /P r =1.50<br />

5.5<br />

5<br />

C90/P r =1.33<br />

4.5<br />

4<br />

C90/P r =1.25<br />

3.5<br />

3<br />

2.5<br />

C 90 /P r =1.10<br />

2<br />

1.5<br />

C 90 /P r =1.00<br />

C<br />

1<br />

90 /P r =.90<br />

C 90 /P r =.80<br />

0.5<br />

0 0.5 1 1.5 2 2.5 3<br />

a 3l<br />

A<br />

Fig. 53. Low load factor (a 3P ) vs. lubricant life factor (a 3l )<br />

and C 90/P r ratio.<br />

TIMKEN MACHINE TOOL CATALOG 51