Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ENGINEERING<br />

A<br />

HEAT GENERATION AND DISSIPATION<br />

TAPERED ROLLER BEARINGS<br />

Heat Generation<br />

Under normal operating conditions, most of the torque and heat<br />

generated by the bearing is due to the elastohydrodynamic losses<br />

at the contact area between rollers and races.<br />

The following equation is used to calculate the heat generated by<br />

the bearing:<br />

Q gen = k 4n M<br />

M = k 1G 1 (nμ) 0.62 (P eq) 0.3<br />

Where:<br />

Q gen = generated heat (W or Btu/min)<br />

M = running torque N.m or lbf-in.<br />

n = rotational speed (RPM)<br />

G 1 = geometry factor from bearing data tables<br />

μ = viscosity at operating temperature (cP)<br />

P eq = dynamic equivalent load (N or lbf)<br />

k 1 = bearing torque constant<br />

= 2.56 x 10 -6 <strong>for</strong> M in N-m<br />

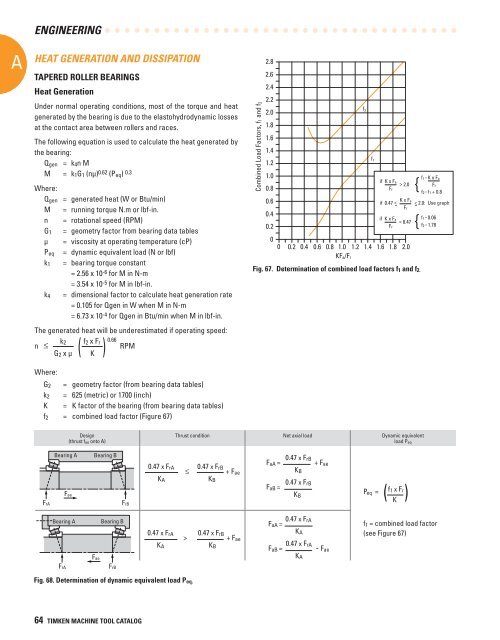

Fig. 67. Determination of combined load factors f 1 and f 2.<br />

= 3.54 x 10 -5 <strong>for</strong> M in lbf-in.<br />

k 4 = dimensional factor to calculate heat generation rate<br />

= 0.105 <strong>for</strong> Qgen in W when M in N-m<br />

= 6.73 x 10 -4 <strong>for</strong> Qgen in Btu/min when M in lbf-in.<br />

The generated heat will be underestimated if operating speed:<br />

n<br />

k 2<br />

( f2 x ) Fr 0.66 RPM<br />

G 2 x μ K<br />

Where:<br />

G 2 = geometry factor (from bearing data tables)<br />

k 2 = 625 (metric) or 1700 (inch)<br />

K = K factor of the bearing (from bearing data tables)<br />

f 2 = combined load factor (Figure 67)<br />

Design<br />

(thrust f ae onto A)<br />

Thrust condition Net axial load Dynamic equivalent<br />

load P eq<br />

Bearing A Bearing B<br />

F aA = 0.47 x FrB + F<br />

0.47 x F ae<br />

rA 0.47 x F rB<br />

≤<br />

+ Fae<br />

K B<br />

K A K B<br />

0.47 x FrB<br />

F aB =<br />

K B<br />

P eq =<br />

( f1 x )<br />

Fr Fae<br />

K<br />

FrA<br />

FrB<br />

Bearing A<br />

Bearing B<br />

0.47 x FrA<br />

F aA =<br />

0.47 x F rA<br />

><br />

0.47 x F rB + Fae<br />

K A<br />

K A<br />

K B<br />

F aB = 0.47 x FrA - F ae<br />

Fae<br />

K A<br />

FrA<br />

FrB<br />

Combined Load Factors, f1 and f2<br />

2.8<br />

2.6<br />

2.4<br />

2.2<br />

2.0<br />

1.8<br />

1.6<br />

1.4<br />

1.2<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0<br />

KF a /F r<br />

f 2<br />

f 1<br />

if K x Fa<br />

> 2.0<br />

Fr<br />

if K x Fa<br />

= 0.47<br />

Fr<br />

f1 = K x Fa<br />

Fr<br />

{<br />

f2 = f1 + 0.8<br />

K x Fa<br />

if 0.47 < < 2.0: Use graph<br />

- Fr -<br />

{<br />

f1 = 0.06<br />

f2 = 1.78<br />

f 1 = combined load factor<br />

(see Figure 67)<br />

64 TIMKEN MACHINE TOOL CATALOG