Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A<br />

ENGINEERING<br />

BALL BEARINGS<br />

Even though ball bearings have the least amount of friction of any<br />

of the common rolling bearings, lubrication is required to minimize<br />

rolling resistance due to de<strong>for</strong>mation of the balls in the raceways<br />

under load, and to minimize any sliding friction that occurs between<br />

the balls, the raceway and the cage. Lubrication also serves to<br />

protect the accurately ground and polished surfaces from corrosion.<br />

In addition, lubrication in general dissipates generated heat and can<br />

help protect the bearing from the entry of <strong>for</strong>eign matter.<br />

Regardless of the method of lubrication or type of lubricant, it is<br />

important that quality lubricants be used to minimize oxidation,<br />

gumming or sludging and that the lubricant be clean and free of<br />

moisture to minimize wear.<br />

Only enough lubrication to accomplish these purposes should be<br />

used since another source of heat may become present, namely<br />

friction between the lubricant and the moving parts, in the <strong>for</strong>m of<br />

churning or internal shear of the lubricant itself.<br />

In the lubrication of ball bearings it is important to realize that a small<br />

quantity of oil or grease will, if constantly present in the bearing,<br />

suffice <strong>for</strong> its requirements. It should be noted that trouble can<br />

result from too much lubrication just as it can from too little. Both<br />

conditions should be avoided. Excessive oil or grease will result<br />

in high temperature and possible damage. When grease is used,<br />

it is necessary to take into consideration the maximum operating<br />

temperature. Particular attention must be given to the housing<br />

design relating to the proximity of the grease to the bearing, to<br />

assure adequate purge room and grease retention.<br />

Depending upon operating speeds, loads and temperatures,<br />

machine tool ball bearings are lubricated with grease, oil or oil mist.<br />

In general, oils are required when bearings operate at high speeds<br />

as they provide greater cooling than is possible with grease.<br />

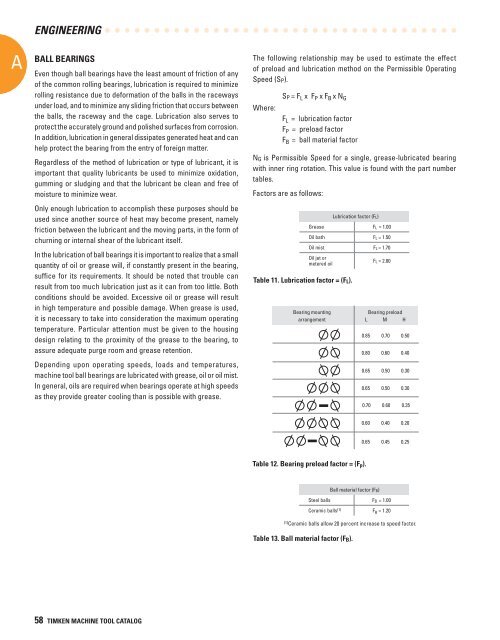

The following relationship may be used to estimate the effect<br />

of preload and lubrication method on the Permissible Operating<br />

Speed (S P).<br />

Where:<br />

S P = F L x F P x F B x N G<br />

F L = lubrication factor<br />

F P = preload factor<br />

F B = ball material factor<br />

N G is Permissible Speed <strong>for</strong> a single, grease-lubricated bearing<br />

with inner ring rotation. This value is found with the part number<br />

tables.<br />

Factors are as follows:<br />

Lubrication factor (F L)<br />

Grease F L = 1.00<br />

Oil bath F L = 1.50<br />

Oil mist F L = 1.70<br />

Oil jet or<br />

metered oil<br />

F L = 2.00<br />

Table 11. Lubrication factor = (F L).<br />

Bearing mounting<br />

arrangement<br />

Bearing preload<br />

L M H<br />

0.85 0.70 0.50<br />

0.80 0.60 0.40<br />

0.65 0.50 0.30<br />

0.65 0.50 0.30<br />

0.70 0.60 0.35<br />

0.60 0.40 0.20<br />

0.65 0.45 0.25<br />

Table 12. Bearing preload factor = (F p).<br />

Ball material factor (F B)<br />

Steel balls F B = 1.00<br />

Ceramic balls (1) F B = 1.20<br />

(1) Ceramic balls allow 20 percent increase to speed factor.<br />

Table 13. Ball material factor (F B).<br />

58 TIMKEN MACHINE TOOL CATALOG