Solid Radioactive Waste Strategy Report.pdf - UK EPR

Solid Radioactive Waste Strategy Report.pdf - UK EPR

Solid Radioactive Waste Strategy Report.pdf - UK EPR

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>EPR</strong> <strong>UK</strong><br />

N° NESH-G/2008/en/0123<br />

REV. A PAGE 218 / 257<br />

Shielding<br />

The TN DUO design features have been chosen to comply with the following storage and<br />

transport requirements:<br />

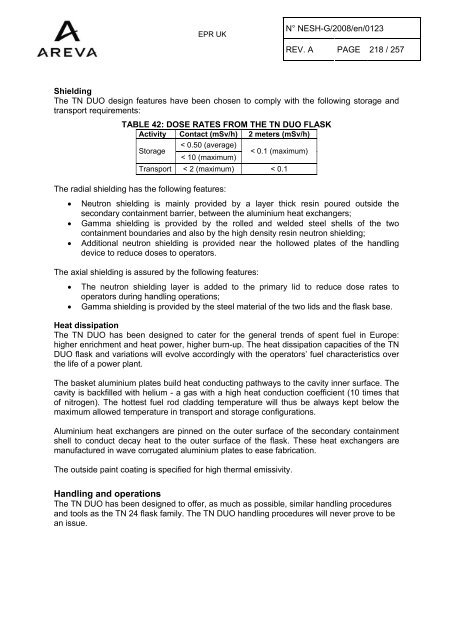

TABLE 42: DOSE RATES FROM THE TN DUO FLASK<br />

Activity Contact (mSv/h) 2 meters (mSv/h)<br />

Storage<br />

< 0.50 (average)<br />

< 10 (maximum)<br />

< 0.1 (maximum)<br />

Transport < 2 (maximum) < 0.1<br />

The radial shielding has the following features:<br />

· Neutron shielding is mainly provided by a layer thick resin poured outside the<br />

secondary containment barrier, between the aluminium heat exchangers;<br />

· Gamma shielding is provided by the rolled and welded steel shells of the two<br />

containment boundaries and also by the high density resin neutron shielding;<br />

· Additional neutron shielding is provided near the hollowed plates of the handling<br />

device to reduce doses to operators.<br />

The axial shielding is assured by the following features:<br />

· The neutron shielding layer is added to the primary lid to reduce dose rates to<br />

operators during handling operations;<br />

· Gamma shielding is provided by the steel material of the two lids and the flask base.<br />

Heat dissipation<br />

The TN DUO has been designed to cater for the general trends of spent fuel in Europe:<br />

higher enrichment and heat power, higher burn-up. The heat dissipation capacities of the TN<br />

DUO flask and variations will evolve accordingly with the operators’ fuel characteristics over<br />

the life of a power plant.<br />

The basket aluminium plates build heat conducting pathways to the cavity inner surface. The<br />

cavity is backfilled with helium - a gas with a high heat conduction coefficient (10 times that<br />

of nitrogen). The hottest fuel rod cladding temperature will thus be always kept below the<br />

maximum allowed temperature in transport and storage configurations.<br />

Aluminium heat exchangers are pinned on the outer surface of the secondary containment<br />

shell to conduct decay heat to the outer surface of the flask. These heat exchangers are<br />

manufactured in wave corrugated aluminium plates to ease fabrication.<br />

The outside paint coating is specified for high thermal emissivity.<br />

Handling and operations<br />

The TN DUO has been designed to offer, as much as possible, similar handling procedures<br />

and tools as the TN 24 flask family. The TN DUO handling procedures will never prove to be<br />

an issue.