Solid Radioactive Waste Strategy Report.pdf - UK EPR

Solid Radioactive Waste Strategy Report.pdf - UK EPR

Solid Radioactive Waste Strategy Report.pdf - UK EPR

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

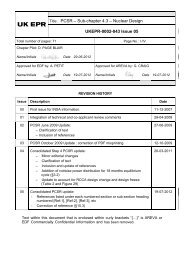

<strong>EPR</strong> <strong>UK</strong><br />

N° NESH-G/2008/en/0123<br />

REV. A PAGE 99 / 257<br />

· Various cutting techniques will be available to size reduce equipment. The most<br />

appropriate technique will be applied depending on specific physical characteristics of the<br />

piece (size, thickness, type of material) and intervention principles. The following can be<br />

used:<br />

o Steam generators: thermal (plasma, torch), mechanical (circular saw, band saw);<br />

o Reactor coolant pump: thermal (plasma, torch), mechanical;<br />

o Main Coolant Pipe: thermal (plasma), mechanical (tool used for SG replacement);<br />

o Pressuriser: thermal (torch);<br />

o Reactor pressure vessel internals: thermal (plasma), mechanical (circular or band<br />

saw), abrasive water jet;<br />

o Pressure vessel / pressure vessel head: thermal (plasma), mechanical (circular<br />

saw);<br />

o Reactor pit concrete: diamond wires and core boring tools, circular saw;<br />

o Reactor pressure vessel supporting ring: circular saw.<br />

· Decontamination techniques:<br />

o<br />

o<br />

Full decontamination process is scheduled for the primary circuit, using a process<br />

such as CORD-UV. The process will be performed on the intact primary circuit<br />

after defuelling. The CORD-UV process allows:<br />

· the oxidation to carbon dioxide by means of UV (ultraviolet light) of the<br />

organic chemicals that are used;<br />

· the completion of the entire decontamination with only one fill of water as<br />

the circulation water is cleaned by ion exchange;<br />

· the removal of the oxide layers present and a controlled dissolution of a<br />

layer of base metal material;<br />

· The cycle sequence of the decontamination (pre-oxidation, reduction,<br />

decontamination, chemical decontamination) may be repeated until the<br />

activity is removed and fixed on ion exchange resins;<br />

· The use of UV wet oxidation and ion exchange minimises the amount of<br />

secondary waste produced.<br />

Item specific decontamination will be performed in a workshop to allow some<br />

reclassification and even recycling or controlled clearance for disposal (on a case<br />

by case basis).<br />

This baseline can be adapted to include additional options such as:<br />

1. Removal of components (reactor pressure vessel, steam generator) in one piece as<br />

demonstrated with various projects worldwide. This may:<br />

· Reduce operations and need of auxiliary installations;<br />

· Reduce duration of the decommissioning;<br />

· Allow recycling of the reactor component materials to fabricate waste containers to<br />

minimise volume for disposal.<br />

2. The steam generators may be fully dismantled and packaged within the reactor<br />

containment building.