IP 55 Modular Cabinets

IP 55 Modular Cabinets

IP 55 Modular Cabinets

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

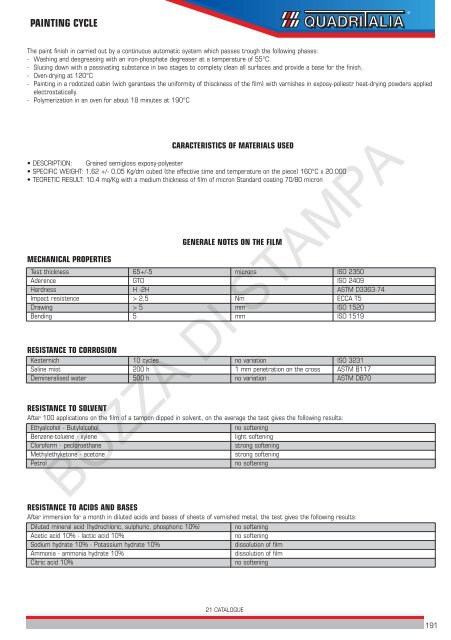

PAINTING CYCLE<br />

The paint finish in carried out by a continuous automatic system which passes trough the following phases:<br />

- Washing and desgreasing with an iron-phosphate degreaser at a temperature of <strong>55</strong>°C.<br />

- Slucing down with a passivating substance in two stages to complety clean all surfaces and provide a base for the finish.<br />

- Oven-drying at 120°C<br />

- Painting in a rodotized cabin (wich garantees the uniformity of thisckness of the film) with varnishes in exposy-poliestr heat-drying powders applied<br />

electrostatically.<br />

- Polymerization in an oven for about 18 minutes at 190°C<br />

CARACTERISTICS OF MATERIALS USED<br />

• DESCR<strong>IP</strong>TION: Grained semigloss exposy-polyester<br />

• SPECIFIC WEIGHT: 1,62 +/- 0,05 Kg/dm cubed (the effective time and temperature on the piece) 160°C x 20.000<br />

• TEORETIC RESULT: 10.4 mq/Kg with a medium thickness of film of micron Standard coating 70/80 micron<br />

GENERALE NOTES ON THE FILM<br />

MECHANICAL PROPERTIES<br />

Test thickness 65+/-5 microns ISO 2350<br />

Aderence GTO ISO 2409<br />

Hardness H -2H ASTM D3363-74<br />

Impact resistence > 2,5 Nm ECCA T5<br />

Drawing > 5 mm ISO 1520<br />

Bending 5 mm ISO 1519<br />

RESISTANCE TO CORROSION<br />

Kesternich 10 cycles no variation ISO 3231<br />

Saline mist 200 h 1 mm penetration on the cross ASTM B117<br />

Demineralised water 500 h no variation ASTM D870<br />

RESISTANCE TO SOLVENT<br />

After 100 applications on the film of a tampon dipped in solvent, on the average the test gives the following results:<br />

Ethyalcohol - Butylalcohol<br />

no softening<br />

Benzene-toluene - xylene<br />

light softening<br />

Cloroform - pecloroethane<br />

strong softening<br />

Methylethyketone - acetone<br />

strong softening<br />

Petrol<br />

no softening<br />

BOZZA DI STAMPA<br />

RESISTANCE TO ACIDS AND BASES<br />

After immersion for a month in diluted acids and bases of sheets of varnished metal, the test gives the following results:<br />

Diluted mineral acid (hydrochloric, sulphuric, phosphoric 10%)<br />

no softening<br />

Acetic acid 10% - lactic acid 10%<br />

no softening<br />

Sodium hydrate 10% - Potassium hydrate 10%<br />

dissolution of film<br />

Ammonia - ammonia hydrate 10%<br />

dissolution of film<br />

Citric acid 10%<br />

no softening<br />

21 CATALOGUE<br />

191