WEIGH SCALE BLENDER® - Maguire Products

WEIGH SCALE BLENDER® - Maguire Products

WEIGH SCALE BLENDER® - Maguire Products

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

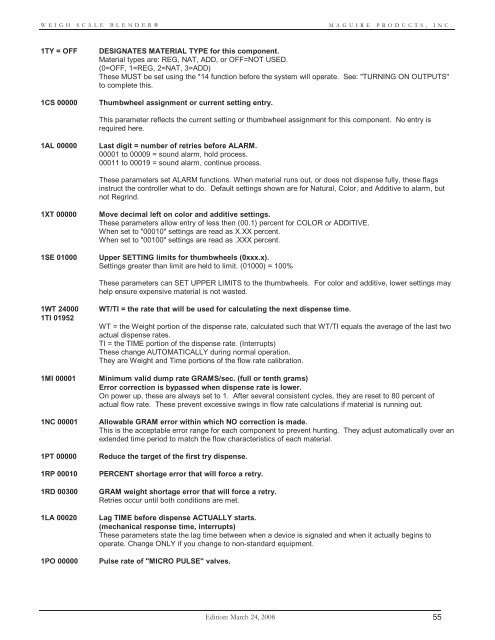

<strong>WEIGH</strong> <strong>SCALE</strong> <strong>BLENDER®</strong><br />

MAGUIRE PRODUCTS, INC.<br />

1TY = OFF<br />

1CS 00000<br />

DESIGNATES MATERIAL TYPE for this component.<br />

Material types are: REG, NAT, ADD, or OFF=NOT USED.<br />

(0=OFF, 1=REG, 2=NAT, 3=ADD)<br />

These MUST be set using the *14 function before the system will operate. See: "TURNING ON OUTPUTS"<br />

to complete this.<br />

Thumbwheel assignment or current setting entry.<br />

This parameter reflects the current setting or thumbwheel assignment for this component. No entry is<br />

required here.<br />

1AL 00000<br />

Last digit = number of retries before ALARM.<br />

00001 to 00009 = sound alarm, hold process.<br />

00011 to 00019 = sound alarm, continue process.<br />

These parameters set ALARM functions. When material runs out, or does not dispense fully, these flags<br />

instruct the controller what to do. Default settings shown are for Natural, Color, and Additive to alarm, but<br />

not Regrind.<br />

1XT 00000<br />

1SE 01000<br />

Move decimal left on color and additive settings.<br />

These parameters allow entry of less then (00.1) percent for COLOR or ADDITIVE.<br />

When set to "00010" settings are read as X.XX percent.<br />

When set to "00100" settings are read as .XXX percent.<br />

Upper SETTING limits for thumbwheels (0xxx.x).<br />

Settings greater than limit are held to limit. (01000) = 100%<br />

These parameters can SET UPPER LIMITS to the thumbwheels. For color and additive, lower settings may<br />

help ensure expensive material is not wasted.<br />

1WT 24000<br />

1TI 01952<br />

1MI 00001<br />

1NC 00001<br />

1PT 00000<br />

1RP 00010<br />

1RD 00300<br />

1LA 00020<br />

1PO 00000<br />

WT/TI = the rate that will be used for calculating the next dispense time.<br />

WT = the Weight portion of the dispense rate, calculated such that WT/TI equals the average of the last two<br />

actual dispense rates.<br />

TI = the TIME portion of the dispense rate. (Interrupts)<br />

These change AUTOMATICALLY during normal operation.<br />

They are Weight and Time portions of the flow rate calibration.<br />

Minimum valid dump rate GRAMS/sec. (full or tenth grams)<br />

Error correction is bypassed when dispense rate is lower.<br />

On power up, these are always set to 1. After several consistent cycles, they are reset to 80 percent of<br />

actual flow rate. These prevent excessive swings in flow rate calculations if material is running out.<br />

Allowable GRAM error within which NO correction is made.<br />

This is the acceptable error range for each component to prevent hunting. They adjust automatically over an<br />

extended time period to match the flow characteristics of each material.<br />

Reduce the target of the first try dispense.<br />

PERCENT shortage error that will force a retry.<br />

GRAM weight shortage error that will force a retry.<br />

Retries occur until both conditions are met.<br />

Lag TIME before dispense ACTUALLY starts.<br />

(mechanical response time, interrupts)<br />

These parameters state the lag time between when a device is signaled and when it actually begins to<br />

operate. Change ONLY if you change to non-standard equipment.<br />

Pulse rate of "MICRO PULSE" valves.<br />

Edition: March 24, 2008 55