MOTOX gearbox - DS TECH

MOTOX gearbox - DS TECH

MOTOX gearbox - DS TECH

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

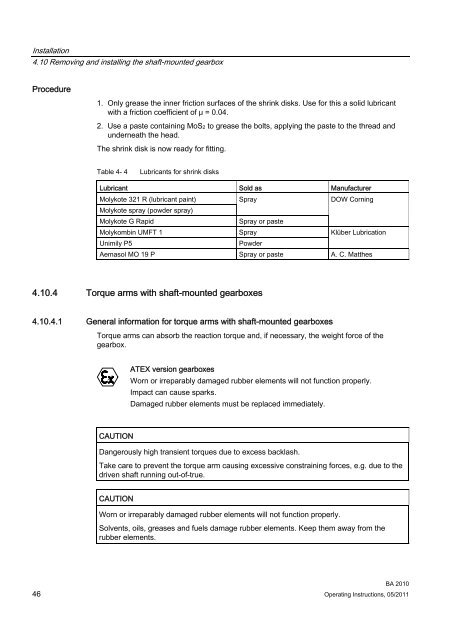

Installation4.10 Removing and installing the shaft-mounted <strong>gearbox</strong>Procedure1. Only grease the inner friction surfaces of the shrink disks. Use for this a solid lubricantwith a friction coefficient of μ = 0.04.2. Use a paste containing MoS2 to grease the bolts, applying the paste to the thread andunderneath the head.The shrink disk is now ready for fitting.Table 4- 4Lubricants for shrink disksLubricant Sold as ManufacturerMolykote 321 R (lubricant paint)SprayDOW CorningMolykote spray (powder spray)Molykote G RapidSpray or pasteMolykombin UMFT 1SprayKlüber LubricationUnimily P5PowderAemasol MO 19 P Spray or paste A. C. Matthes4.10.4 Torque arms with shaft-mounted <strong>gearbox</strong>es4.10.4.1 General information for torque arms with shaft-mounted <strong>gearbox</strong>esTorque arms can absorb the reaction torque and, if necessary, the weight force of the<strong>gearbox</strong>.ATEX version <strong>gearbox</strong>esWorn or irreparably damaged rubber elements will not function properly.Impact can cause sparks.Damaged rubber elements must be replaced immediately.CAUTIONDangerously high transient torques due to excess backlash.Take care to prevent the torque arm causing excessive constraining forces, e.g. due to thedriven shaft running out-of-true.CAUTIONWorn or irreparably damaged rubber elements will not function properly.Solvents, oils, greases and fuels damage rubber elements. Keep them away from therubber elements.BA 201046 Operating Instructions, 05/2011