- Page 1 and 2:

Wind Energy Proceedings of the Euro

- Page 3 and 4:

Prof. Dr. Joachim Peinke Dr. Stepha

- Page 5 and 6:

VI Preface been presented, spanning

- Page 7 and 8:

VIII Contents 3.3 Stochastic Wind F

- Page 9 and 10:

X Contents 12.6 Subgrid Scale Turbu

- Page 11 and 12:

XII Contents 22 Stochastic Small-Sc

- Page 13 and 14:

XIV Contents 32 Handling Systems Dr

- Page 15 and 16:

XVI Contents 41 3D Numerical Simula

- Page 17 and 18:

XVIII Contents 51 Comparing WAsP an

- Page 19 and 20:

XX Contents 58.3 Ultra-High Perform

- Page 21 and 22:

XXII List of Contributors Lars Berg

- Page 23 and 24:

XXIV List of Contributors Renata Gn

- Page 25 and 26:

XXVI List of Contributors A. Kiss D

- Page 27 and 28:

XXVIII List of Contributors El˙zbi

- Page 29 and 30:

XXX List of Contributors Ivo Sláde

- Page 31 and 32:

1 Offshore Wind Power Meteorology B

- Page 33 and 34:

1 Offshore Wind Power Meteorology 3

- Page 35 and 36:

1 Offshore Wind Power Meteorology 5

- Page 37 and 38:

2 Wave Loads on Wind-Power Plants i

- Page 39 and 40:

Trubaduren 2 Wave Loads on Wind-Pow

- Page 41 and 42:

Base moment (10 6 Nm) 0.4 0.2 −0.

- Page 43 and 44:

2 Wave Loads on Wind-Power Plants i

- Page 45 and 46:

3 Time Domain Comparison of Simulat

- Page 47 and 48:

3 Time Domain Comparison Using Cons

- Page 49 and 50:

7.0 6.0 5.0 4.0 3.0 2.0 1.0 0.0 3 T

- Page 51 and 52:

4 Mean Wind and Turbulence in the A

- Page 53 and 54:

4 Mean Wind and Turbulence in the A

- Page 55 and 56:

4 Mean Wind and Turbulence in the A

- Page 57 and 58:

5 Wind Speed Profiles above the Nor

- Page 59 and 60:

5 Wind Speed Profiles above the Nor

- Page 61 and 62:

Height [m] 100 90 80 70 60 50 40 30

- Page 63 and 64:

6 Fundamental Aspects of Fluid Flow

- Page 65 and 66:

f Suu(f, z) / σ 2 u(z) 10 0 10 −

- Page 67 and 68:

a) c) −0,375 6 Fluid Flow over Co

- Page 69 and 70:

7 Models for Computer Simulation of

- Page 71 and 72:

y/h 2.5 2 1.5 1 0.5 0 7 Models for

- Page 73 and 74:

8 Power Performance via Nacelle Ane

- Page 75 and 76:

8 Power Performance via Nacelle Ane

- Page 77 and 78:

8 Power Performance via Nacelle Ane

- Page 79 and 80:

9 Pollutant Dispersion in Flow Arou

- Page 81 and 82:

x1/B 0.3 0.5 0.8 1.0 9 Pollutant Di

- Page 83 and 84:

9 Pollutant Dispersion in Flow Arou

- Page 85 and 86:

10 On the Atmospheric Flow Modellin

- Page 87 and 88:

10 On the Atmospheric Flow Modellin

- Page 89 and 90:

10 On the Atmospheric Flow Modellin

- Page 91 and 92:

11 Comparison of Logarithmic Wind P

- Page 93 and 94:

Height above ground in m 100 90 80

- Page 95 and 96:

12 Turbulence Modelling and Numeric

- Page 97 and 98:

12 Turbulence Modelling and Numeric

- Page 99 and 100:

12 Turbulence Modelling and Numeric

- Page 101 and 102:

12 Turbulence Modelling and Numeric

- Page 103 and 104:

13 Gusts in Intermittent Wind Turbu

- Page 105 and 106:

13 Gusts in Intermittent Wind Turbu

- Page 107 and 108:

Durations (s) 25 20 15 10 5 13 Gust

- Page 109 and 110:

13 Gusts in Intermittent Wind Turbu

- Page 111 and 112:

14 Report on the Research Project O

- Page 113 and 114:

height z (m) 100 80 60 40 20 0 14 R

- Page 115 and 116:

14.6 Outlook 14 Report on the Resea

- Page 117 and 118:

15 Simulation of Turbulence, Gusts

- Page 119 and 120:

S(ƒ)(m/s) 2 /Hz 15 Simulation of T

- Page 121 and 122:

15 Simulation of Turbulence, Gusts

- Page 123 and 124:

16 Short Time Prediction of Wind Sp

- Page 125 and 126:

ms prediction error [m/s] 16 Short

- Page 127 and 128:

16 Short Time Prediction of Wind Sp

- Page 129 and 130:

17 Wind Extremes and Scales: Multif

- Page 131 and 132:

Log10 E(k)*k**(5/3) 6 4 2 0 5/3 cor

- Page 133 and 134:

17.3 Discussion and Conclusion 17 W

- Page 135 and 136:

18 Boundary-Layer Influence on Extr

- Page 137 and 138:

z/H (a) (b) 4 2 18 Boundary-Layer I

- Page 139 and 140:

18.6 Concluding Remarks 18 Boundary

- Page 141 and 142:

19 The Statistical Distribution of

- Page 143 and 144:

19 The Statistical Distribution of

- Page 145 and 146:

20 Superposition Model for Atmosphe

- Page 147 and 148:

h(u) 0.5 0.3 0.1 20 Superposition M

- Page 149 and 150:

21 Extreme Events Under Low-Frequen

- Page 151 and 152:

21 Extreme Events Under Low-Frequen

- Page 153 and 154:

22 Stochastic Small-Scale Modelling

- Page 155 and 156:

p(σ⏐u) 1 0.8 0.6 0.4 0.2 22 Stoc

- Page 157 and 158:

22 Stochastic Small-Scale Modelling

- Page 159 and 160:

23 Quantitative Estimation of Drift

- Page 161 and 162:

23 Quantitative Estimation of Drift

- Page 163 and 164:

23 Quantitative Estimation of Drift

- Page 165 and 166:

24 Scaling Turbulent Atmospheric St

- Page 167 and 168:

24 Scaling Turbulent Atmospheric St

- Page 169 and 170:

25 Wind Farm Power Fluctuations P.

- Page 171 and 172:

25 Wind Farm Power Fluctuations 141

- Page 173 and 174:

d rc q rc V 0 q V 25 Wind Farm Powe

- Page 175 and 176:

References 25 Wind Farm Power Fluct

- Page 177 and 178:

26 Network Perspective of Wind-Powe

- Page 179 and 180:

26 Network Perspective of Wind-Powe

- Page 181 and 182:

26 Network Perspective of Wind-Powe

- Page 183 and 184:

27 Phenomenological Response Theory

- Page 185 and 186:

27 Phenomenological Response Theory

- Page 187 and 188:

27 Phenomenological Response Theory

- Page 189 and 190:

28 Turbulence Correction for Power

- Page 191 and 192:

28 Turbulence Correction for Power

- Page 193 and 194:

29 Online Modeling of Wind Farm Pow

- Page 195 and 196:

29 Online Modeling of Wind Farm Pow

- Page 197 and 198:

30 Uncertainty of Wind Energy Estim

- Page 199 and 200:

30 Uncertainty of Wind Energy Estim

- Page 201 and 202:

30 Uncertainty of Wind Energy Estim

- Page 203 and 204:

31 Characterisation of the Power Cu

- Page 205 and 206:

31 Characterisation of the Power Cu

- Page 207 and 208:

31 Characterisation of the Power Cu

- Page 209 and 210:

32 Handling Systems Driven by Diffe

- Page 211 and 212:

32 Handling Systems Driven by Diffe

- Page 213 and 214:

33 Experimental Researches of Chara

- Page 215 and 216:

33 Experimental Researches of Chara

- Page 217 and 218:

34 Methodical Failure Detection in

- Page 219 and 220:

34 Methodical Failure Detection in

- Page 221 and 222:

35 Modelling of the Transition Loca

- Page 223 and 224:

35 Modelling an Airfoil with Surfac

- Page 225 and 226:

(Cl/Cd)max 120 110 100 90 80 70 60

- Page 227 and 228:

35 Modelling an Airfoil with Surfac

- Page 229 and 230:

36 Helicopter Aerodynamics with Emp

- Page 231 and 232:

36 Helicopter Aerodynamics with Emp

- Page 233 and 234:

36 Helicopter Aerodynamics with Emp

- Page 235 and 236:

37 Determination of Angle of Attack

- Page 237 and 238:

37 Determination of Angle of Attack

- Page 239 and 240:

Drag coefficient 0.5 0.4 0.3 0.2 0.

- Page 241 and 242:

38 Unsteady Characteristics of Flow

- Page 243 and 244:

PSD PSD 38 Unsteady Characteristics

- Page 245 and 246:

39 Aerodynamic Multi-Criteria Shape

- Page 247 and 248:

39 Multi-Criteria Shape Optimizatio

- Page 249 and 250:

39 Multi-Criteria Shape Optimizatio

- Page 251 and 252:

40 Rotation and Turbulence Effects

- Page 253 and 254:

Cp Xsep/c 1 0.6 0.2 −0.2 −0.6

- Page 255 and 256:

Standard deviation of Cp 0.7 0.6 0.

- Page 257 and 258:

41 3D Numerical Simulation and Eval

- Page 259 and 260:

41 3D-CFD-Simulation of a Wind Turb

- Page 261 and 262:

42 Performance of the Risø-B1 Airf

- Page 263 and 264:

42 Performance of the Risø-B1 Airf

- Page 265 and 266:

43 Aerodynamic Behaviour of a New T

- Page 267 and 268:

43 Aerodynamic Behaviour of a New T

- Page 269 and 270:

43 Aerodynamic Behaviour of a New T

- Page 271 and 272:

44 Numerical Simulation of Dynamic

- Page 273 and 274: 44 Numerical Simulation of Dynamic

- Page 275 and 276: 45 Modeling of the Far Wake behind

- Page 277 and 278: 8 6 uz 4 2 45 Modeling of the Far W

- Page 279 and 280: 46 Stability of the Tip Vortices in

- Page 281 and 282: 46 Stability of the Tip Vortices in

- Page 283 and 284: 47 Modelling Turbulence Intensities

- Page 285 and 286: 47 Modelling Turbulence Intensities

- Page 287 and 288: 47 Modelling Turbulence Intensities

- Page 289 and 290: 48 Numerical Computations of Wind T

- Page 291 and 292: Z X Y 48 Numerical Computations of

- Page 293 and 294: References 48 Numerical Computation

- Page 295 and 296: 49 Modelling Wind Turbine Wakes wit

- Page 297 and 298: U mean / U ref 1 0.9 0.8 0.7 49 Mod

- Page 299 and 300: 49.5 Conclusion 49 Modelling Wind T

- Page 301 and 302: 50 Prediction of Wind Turbine Noise

- Page 303 and 304: 0.8 0.6 0.4 0.2 −0.2 −0.4 −0.

- Page 305 and 306: 51 Comparing WAsP and Fluent for Hi

- Page 307 and 308: Table 51.1. Measurements and simula

- Page 309 and 310: 51 Comparing WAsP and Fluent for Hi

- Page 311 and 312: 52 Fatigue Assessment of Truss Join

- Page 313 and 314: 52 Fatigue Assessment of Truss Join

- Page 315 and 316: 52 Fatigue Assessment of Truss Join

- Page 317 and 318: 53 Advances in Offshore Wind Techno

- Page 319 and 320: Simulation Measurement pitch angle

- Page 321 and 322: 53 Advances in Offshore Wind Techno

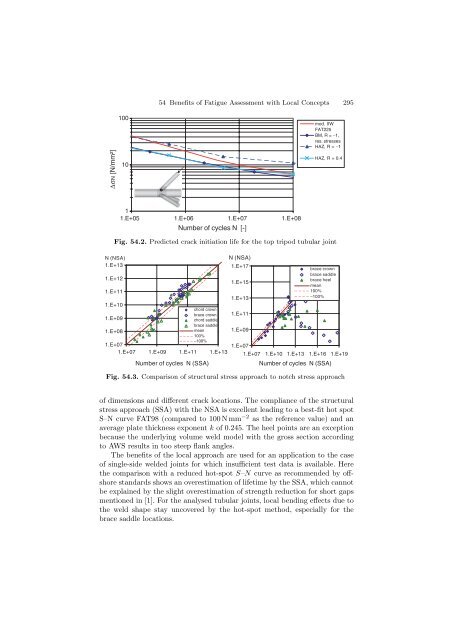

- Page 323: 54 Benefits of Fatigue Assessment w

- Page 327 and 328: 55 Extension of Life Time of Welded

- Page 329 and 330: Transverse residual stresses [N/mm

- Page 331 and 332: 56 Damage Detection on Structures o

- Page 333 and 334: 56 Damage Detection on Structures o

- Page 335 and 336: 57 Influence of the Type and Size o

- Page 337 and 338: [W/m 2 ] q t [W/m 5000 4000 3000 20

- Page 339 and 340: 58 High-cycle Fatigue of “Ultra-H

- Page 341 and 342: (a) (b) 450 Load [kN] 400 350 300 2

- Page 343 and 344: 59 A Modular Concept for Integrated

- Page 345 and 346: 59 A Modular Concept for Integrated

- Page 347 and 348: 59 A Modular Concept for Integrated

- Page 349 and 350: 60 Solutions of Details Regarding F

- Page 351 and 352: SR 1000 800 600 400 200 100 80 60 4

- Page 353 and 354: 60 Solutions of Details Regarding F

- Page 355 and 356: 61 On the Influence of Low-Level Je

- Page 357 and 358: Relative Power and Loading [%] 61 O

- Page 359 and 360: 62 Reliability of Wind Turbines Exp

- Page 361 and 362: 62 Reliability of Wind Turbines 331

- Page 363: This page intentionally left blank