- Page 2 and 3: LOS ALAMOS SERIES ON DYNAMIC MATERI

- Page 4 and 5: University of California Press Berk

- Page 6 and 7: PART II. EXPLOSIVES PROPERTIES BY P

- Page 8 and 9: treats pure explosives first, alpha

- Page 10 and 11: EXPLOSIVES PROPERTIES BY EXPLOSIVE

- Page 12 and 13: BARATOL 2.3 Shipping.2 Baratol is s

- Page 14 and 15: BARATOL 6 5.4 Thermal Conductivity.

- Page 16 and 17: BARATOL 6.2 Detonation Pressure. We

- Page 18 and 19: BARATOL REFERENCES . . 1. N. I. Sax

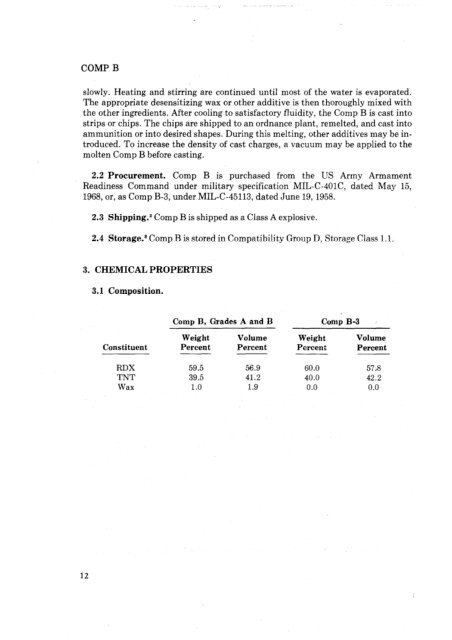

- Page 22 and 23: COMP B 14 3.3 Solubility.‘The sol

- Page 24 and 25: COMP B 16 5.3 Heat Capacity. Heat C

- Page 26 and 27: COMP B 18 6.2 Detonation Pressure.

- Page 28 and 29: COMP B 7.3 Shock Hugoniots.12J8 Com

- Page 30 and 31: COMP B 9. MECHANICAL PROPERTIES 22

- Page 32 and 33: CYCLOTOL 1. GENERAL PROPERTIES 1.1

- Page 34 and 35: CYCLOTOL 26 3.2 Molecular Weight. C

- Page 36 and 37: CYCLOTOL 4.3 Infrared Spectrum. See

- Page 38 and 39: CYCLOTOL where D = detonation veloc

- Page 40 and 41: CYCLOTOL 8.3 Skid Test Results. Den

- Page 42 and 43: DATB 1. GENERAL PROPERTIES 1.1 Chem

- Page 44 and 45: DATB 4. PHYSICAL PROPERTIES 4.1 Cry

- Page 46 and 47: DATB 5.4 Thermal Conductivity, Cond

- Page 48 and 49: DATB 7.3 Shock Hugoniot.9 Density k

- Page 50 and 51: HMX* 1. GENERAL PROPERTIES 1.1 Chem

- Page 52 and 53: HMX 3.2 Molecular Weight. 296.17 3.

- Page 54 and 55: HMX 5. THERMAL PROPERTIES 46 5.1 Ph

- Page 56 and 57: HMX 6. DETONATION PROPERTIES 6.1 De

- Page 58 and 59: HMX 7.3 Shock Hugoniots.” Density

- Page 60 and 61: NITROGUANIDINE 1. GENERAL PROPERTIE

- Page 62 and 63: NQ 54 4.2 Density.’ Crystal Metho

- Page 64 and 65: NQ 56 5.6 Heats of Combustion and F

- Page 66 and 67: NQ 6.2 Detonation Pressure. There a

- Page 68 and 69: NQ 8. SENSITIVITY 8.1 Drop Weight I

- Page 70 and 71:

OCTOL These are shipped to an ordna

- Page 72 and 73:

64 OCTOL 3.3 Solubility.6 The solub

- Page 74 and 75:

OCTOL 5. THERMAL PROPERTIES 66 5.1

- Page 76 and 77:

OCTOL 68 6.4 Plate Dent Test Result

- Page 78 and 79:

OCTOL 8.3 Skid Test Results. Weight

- Page 80 and 81:

PBX 9011 1. GENERAL PROPERTIES 1.1

- Page 82 and 83:

PBX 9011 3.3 Solubility. The solubi

- Page 84 and 85:

PBX 9011 76 5.5 Coefficient of Ther

- Page 86 and 87:

PBX 9011 78 6.3 Cylinder Test Resul

- Page 88 and 89:

PBX 9011 7.5 Detonation Failure Thi

- Page 90 and 91:

PBX 9011 82 9.3 Compressive Strengt

- Page 92 and 93:

PBX9404 1. GENERAL PROPERTIES 1.1 C

- Page 94 and 95:

PBX 9404 86 3.2 Molecular Weight. C

- Page 96 and 97:

PBX 9404 88 4.3 Infrared Spectrum.

- Page 98 and 99:

PBX 9404 > 1 1 o- r 0 I I I, / PYRO

- Page 100 and 101:

PBX 9404 7. SHOCK INITIATION PROPER

- Page 102 and 103:

PBX 9404 7.5 Detonation Failure Thi

- Page 104 and 105:

PBX 9404 8.5 Spark Sensitivity. Ele

- Page 106 and 107:

PBX 9404 REFERENCE‘S 1. Committee

- Page 108 and 109:

PBX 9407 2.3 Shipping.2 PBX-9407 mo

- Page 110 and 111:

PBX 9407 4.3 Infrared Spectrum. See

- Page 112 and 113:

PBX 9407 6. DETONATION PROPERTIES I

- Page 114 and 115:

PBX 9407 106 7.2 Wedge Test Results

- Page 116 and 117:

PBX 9407 9.3 Compressive Strength a

- Page 118 and 119:

PBX 9501 2.3 Shipping.* PBX-9501mol

- Page 120 and 121:

PBX 9501 5. THERMAL PROPERTIES 112

- Page 122 and 123:

PBX 9501 6. DETONATION PROPERTIES 6

- Page 124 and 125:

PBX 9501 7.3 Shock Hugoniot. Densit

- Page 126 and 127:

PBX 9501 9. MECHANICAL PROPERTIES*

- Page 128 and 129:

PBX9502 1. GENERAL PROPERTIES 1.1 C

- Page 130 and 131:

PBX 9502 3.3 Solubility. The solubi

- Page 132 and 133:

PBX 9502 124 5.3 Heat Capacity. 5.4

- Page 134 and 135:

PBX 9502 6.3 Cylinder Test Results.

- Page 136 and 137:

PBX 9502 9. MECHANICAL PROPERTIES 1

- Page 138 and 139:

PENTAERYTHRITOLTETRANITRATE (PETN)

- Page 140 and 141:

PETN 3.2 Molecular Weight. 316.15 3

- Page 142 and 143:

PETN 4.4 Refractive Indices.s Omega

- Page 144 and 145:

PETN 5.7 Thermal Decomposition Kine

- Page 146 and 147:

PETN 138 7.2 Wedge Test Results. De

- Page 148 and 149:

, PETN 5. US Army Materiel Command,

- Page 150 and 151:

RDX developed into a continuous hig

- Page 152 and 153:

RDX 4. PHYSICAL PROPERTIES 4.1 Crys

- Page 154 and 155:

RDX 146 5.2 Vapor Pressure.8 Temper

- Page 156 and 157:

RDX 6. DETONATION PROPERTIES 148 6.

- Page 158 and 159:

RDX 7.3 Shock Hugoniot.” 8. SENSI

- Page 160 and 161:

TATB 1. GENERAL PROPERTIES 1.1 Chem

- Page 162 and 163:

TATB TATB solubility in sulfuric ac

- Page 164 and 165:

TATB 5.2 Vapor Pressure.6 A least s

- Page 166 and 167:

TATB I / / I I I I I I I ! \ I 1 \

- Page 168 and 169:

TATB 7.3 Shock Hugoniots.“+ A num

- Page 170 and 171:

TATB REFERENCES 1. T. M Benziger an

- Page 172 and 173:

TETRYL acetone. In the second proce

- Page 174 and 175:

TETRYL 2.5 100 80 60 % T 40 20 0 :;

- Page 176 and 177:

TETRYL 6. DETONATION PROPERTIES 6.1

- Page 178 and 179:

TETRYL 7.5 Detonation Failure Thick

- Page 180 and 181:

TNT 1. GENERAL PROPERTIES 1.1 Chemi

- Page 182 and 183:

TNT 4. PHYSICAL PROPERTIES 4.1 Crys

- Page 184 and 185:

TNT 4.3 Infrared Spectrum. See Fig.

- Page 186 and 187:

TNT 178 5.5 Coefficient of Thermal

- Page 188 and 189:

TNT The charge preparation method a

- Page 190 and 191:

TNT 182 6.4 Plate Dent Test Results

- Page 192 and 193:

TNT 7.3 Shock Hugoniots.2aJ4 Densit

- Page 194 and 195:

TNT 9.3 Compressive Strength and Mo

- Page 196 and 197:

XTX8003 1. GENERAL PROPERTIES 1.1 C

- Page 198 and 199:

XTX 8003 3.3 Solubility.6 The solub

- Page 200 and 201:

XTX 8003 5.7 Thermal Decomposition

- Page 202 and 203:

XTX 8003 8. SENSITIVITY 8.1 Drop We

- Page 204 and 205:

XTX8004 1. GENERAL PROPERTIES 1.1 C

- Page 206 and 207:

XTX 8004 3.3 Solubility. The solubi

- Page 208 and 209:

XTX 8004 6. DETONATION PROPERTIES 6

- Page 210 and 211:

PART II EXPLOSIVES PROPERTIES BY IP

- Page 212 and 213:

Explosive Alex/20 Alex/30 Amatex/20

- Page 214 and 215:

Explosive PBX 9007 PBX 9010 PBX 901

- Page 216 and 217:

Explosive Constituents X-0234-60 X-

- Page 218 and 219:

Alex/20 Alex/30 Amatexl20 Amatexl30

- Page 220 and 221:

NQ octo1 PAT0 Explosive PBX 9007 PB

- Page 222 and 223:

X-0234-60 X-0234-70 X-0234-80 X-028

- Page 224 and 225:

THERMAL PROPERTIES 2. THERMAL PROPE

- Page 226 and 227:

THERMAL PROPERTIES k2 = kl - (4, -

- Page 228 and 229:

Explosive PETN RDX TNT Table 2.03 C

- Page 230 and 231:

THERMAL PROPERTIES AEE = standard i

- Page 232 and 233:

THERMAL PROPERTIES Fig. 2.02. Pyrol

- Page 234 and 235:

,’ THERMAL PROPERTIES L Y !s :: B

- Page 236 and 237:

THERMAL PROPERTIES 228 Composition

- Page 238 and 239:

THERMAL PROPERTIES B Y !3 E E “I

- Page 240 and 241:

THERMAL PROPERTIES This assembly is

- Page 242 and 243:

DETONATION PROPERTIES 3. DETONATION

- Page 244 and 245:

DETONATION PROPERTIES 236 Table 3.0

- Page 246 and 247:

Shot No. c-4394 E-4672 E-4067 E-406

- Page 248 and 249:

DETONATION PROPERTIES Table 3.06 CY

- Page 250 and 251:

Table 3.08 OCTOL DETONATION VELOCIT

- Page 252 and 253:

Rate Stick Shot ’ Diameter No. (m

- Page 254 and 255:

DETONATION PROPERTIES 246 Table 3.1

- Page 256 and 257:

Shot No. C-4436 E-3621 - Rate Stick

- Page 258 and 259:

Table 3.15 GENERAL CYLINDER TEST SH

- Page 260 and 261:

DETONATION PROPERTIES 252 Expansion

- Page 262 and 263:

Expansion Radius (mm) Table 3.19 X-

- Page 264 and 265:

N VI UY Table 3.21 X-0285 WALL VELO

- Page 266 and 267:

DETONATION PROPERTIES Table 3.25 X-

- Page 268 and 269:

Explosive Table 3.26 DETONATION (C-

- Page 270 and 271:

DETONATION PROPERTIES Analysis Line

- Page 272 and 273:

DETONATION PROPERTIES Explosive Tab

- Page 274 and 275:

DETONATION PROPERTIES Explosive Tab

- Page 276 and 277:

DETONATION PROPERTIES Explosive Tab

- Page 278 and 279:

DETONATION PROPERTIES Explosive Tab

- Page 280 and 281:

DETONATION PROPERTIES Explosive Tab

- Page 282 and 283:

DETONATION PROPERTIES Explosive Tab

- Page 284 and 285:

DETONATION PROPERTIES Explosive Tab

- Page 286 and 287:

DETONATION PROPERTIES Explosive Tab

- Page 288 and 289:

DETONATION PROPERTIES 3.4 Plate Den

- Page 290 and 291:

Exnlosive Table 3.46 (continued) De

- Page 292 and 293:

Explosive PBX 9501 x-0007 86 HMX/14

- Page 294 and 295:

85 RDX/lS Kel-F Explosive 88 RDXI12

- Page 296 and 297:

DETONATION PROPERTIES Table 3.47 LE

- Page 298 and 299:

DETONATION PROPERTIES Table 3.48 DE

- Page 300 and 301:

SHOCK INITIATION PROPERTIES PETN Ba

- Page 302 and 303:

SHOCK INITIATION PROPERTIES Fig. 4.

- Page 304 and 305:

SHOCK INITIATION PROPERTIES each sh

- Page 306 and 307:

SHOCK INITIATION’PROPERTIES Table

- Page 308 and 309:

SHOCK INITIATION PROPERTIES 300 i;

- Page 310 and 311:

w R Table 4.04 NITROMETHANE Composi

- Page 312 and 313:

SHOCK INITIATION PROPERTIES 304 Tab

- Page 314 and 315:

SHOCK INITIATION PROPERTIES 306 / D

- Page 316 and 317:

SHOCK INITIATION PROPERTIES 308 2 0

- Page 318 and 319:

Table 4.06 (continued) Coordinates

- Page 320 and 321:

SHOCK INITIATION PROPERTIES 312 I-

- Page 322 and 323:

SHOCK INITIATION PROPERTIES 314 4 3

- Page 324 and 325:

SHOCK INITIATION PROPERTIES 316 05

- Page 326 and 327:

Table 4.07 PETN (SINGLE CRYSTAL) Co

- Page 328 and 329:

Table 4.08 (continued) Shot Number

- Page 330 and 331:

SHOCK INITIATION PROPERTIES 322 20

- Page 332 and 333:

SHOCK INITIATION PROPERTIES 324 2 u

- Page 334 and 335:

SHOCK INITIATION PROPERTIES 326 2 0

- Page 336 and 337:

SHOCK INITIATION PROPERTIES Table 4

- Page 338 and 339:

SHOCK INITIATION PROPERTIES Table 4

- Page 340 and 341:

SHOCK INITIATION PROPERTIES Table 4

- Page 342 and 343:

SHOCK INITIATION PROPERTIES 334 2T

- Page 344 and 345:

SHOCK INITIATION PROPERTIES 336 2 2

- Page 346 and 347:

SHOCK INITIATION PROPERTIES 338 2 0

- Page 348 and 349:

Initial Shock Parameters Table 4.12

- Page 350 and 351:

SHOCK INITIATION PROPERTIES 342 Ini

- Page 352 and 353:

SHOCK INITIATION PROPERTIES Table 4

- Page 354 and 355:

3 *a i 8 3 x j > f m e c u,, = (2.3

- Page 356 and 357:

SHOCK INITIATION PROPERTIES 348 Dis

- Page 358 and 359:

w ul 0 Composition 95 wt% DATB, 5 w

- Page 360 and 361:

SHOCK INITIATION PROPERTIES 5.5- 5.

- Page 362 and 363:

5 Table 4.17 (continued) Coordinate

- Page 364 and 365:

SHOCK INITIATION PROPERTIES 356 2 9

- Page 366 and 367:

SHOCK INITIATION PROPERTIES 40- 20

- Page 368 and 369:

Shot E-3120 3.370 $0.022 E-3131 2.4

- Page 370 and 371:

_. Shot Number E-771 E-781 B-4481 B

- Page 372 and 373:

SHOCK INITIATION PROPERTIES 364 2 I

- Page 374 and 375:

SHOCK INITIATION PROPERTIES 366 0.6

- Page 376 and 377:

SHOCK INITIATION PROPERTIES 368 20

- Page 378 and 379:

SHOCK INITIATION PROPERTIES Composi

- Page 380 and 381:

Table 4.21 X-0219-50-14-10 Composit

- Page 382 and 383:

SHOCK INITIATION PROPERTIES 374 3 2

- Page 384 and 385:

Composition 95 wt% NQ, 5 wt% Estane

- Page 386 and 387:

Shot Number (G?a) E-3245 16.2 5.904

- Page 388 and 389:

SHOCK INITIATION PROPERTIES 380 c x

- Page 390 and 391:

w R Table 4.24 (continued) Reduced

- Page 392 and 393:

Table 4.25 XTX-8003 (EXTEX) Composi

- Page 394 and 395:

SHOCK INITIATION PROPERTIES 386 a--

- Page 396 and 397:

Table 4.27 PBX 9407 Compositon 94 w

- Page 398 and 399:

SHOCK INITIATION PROPERTIES 390 3 g

- Page 400 and 401:

Table 4.28 PBX 9405 Cotiposition 93

- Page 402 and 403:

SHOCK INITIATION PROPERTIES 394 c 5

- Page 404 and 405:

% OY Table 4.30 x-0250-40-19 Compos

- Page 406 and 407:

SHOCK INITIATION PROPERTIES 398 Dis

- Page 408 and 409:

Table 4.32 95 TATB/2.5 Kel-F 800/2.

- Page 410 and 411:

SHOCK INITIATION PROPERTIES 402 Tab

- Page 412 and 413:

SHOCK INITIATION PROPERTIES 404 Tab

- Page 414 and 415:

SHOCK INITIATION PROPERTIES 406 Tab

- Page 416 and 417:

Table 4.39 (continued) Coordinates

- Page 418 and 419:

SHOCK INITIATION PROPERTIES Table 4

- Page 420 and 421:

SHOCK INITIATION PROPERTIES Table 4

- Page 422 and 423:

z Table 4.44 FKM CLASS VII PROPELLA

- Page 424 and 425:

SHOCK INITIATION PROPERTIES Table 4

- Page 426 and 427:

SHOCK INITIATION PROPERTIES Table 4

- Page 428 and 429:

Theoretical Maximum Density >1.910

- Page 430 and 431:

SHOCK INITIATION PROPERTIES 422 Tab

- Page 432 and 433:

SHOCK INITIATION PROPERTIES Table 4

- Page 434 and 435:

Ammonium picrate Raratol(76/24) mix

- Page 436 and 437:

HMX-Based PBX 9011 PBX 9404 PBX-950

- Page 438 and 439:

SHOCK INITIATION PROPERTIES 0.360 c

- Page 440 and 441:

SHOCK INITIATION PROPERTIES 432 I I

- Page 442 and 443:

SHOCK INITIATION PROPERTIES Fig. 4.

- Page 444 and 445:

SHOCK INITIATION PROPERTIES Explosi

- Page 446 and 447:

SHOCK INITIATION PROPERTIES Table 4

- Page 448 and 449:

SHOCK INITIATION PROPERTIES TRANSIT

- Page 450 and 451:

SHOCK INITIATION PROPERTIES 442 FOI

- Page 452 and 453:

SHOCK INITIATION PROPERTIES 444 Tab

- Page 454 and 455:

SENSITIVITY TESTS 5. SENSITIVITY TE

- Page 456 and 457:

Ammonium nitrate Ammonium picrate B

- Page 458 and 459:

-’ .-- _- ..- _ “. Cyclotol75/2

- Page 460 and 461:

Explosive RDX-Based with Metal Fill

- Page 462 and 463:

SENSITIVITY TESTS 5.2 Skid Test. Th

- Page 464 and 465:

Explosive Comp A-3 1.638 45 PBX 901

- Page 466 and 467:

SENSITIVITY TESTS 5.3 Large-Scale D

- Page 468 and 469:

SENSITIVITY TESTS 5.4 Spark Sensiti

- Page 470 and 471:

GLOSSARY ABH Amatex-20 ATNI BDNPA B

- Page 472 and 473:

NP OFHC ONT P-16 P-22 P-40 P-80 P-1

- Page 474 and 475:

AUTHOR IND Ablard, J. E. 141, 151 A

- Page 476 and 477:

SUBJECT INDEX ABH 461 Alex/20 204,

- Page 478 and 479:

pentaerythritol tetranitrate (PETN)