Vision and Challenges for Realising the Internet of Things

Vision and Challenges for Realising the Internet of Things

Vision and Challenges for Realising the Internet of Things

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

terfaces introduced in <strong>the</strong> Indisputable Key project support integration <strong>of</strong> non EPC st<strong>and</strong>ard<br />

readers to Traceability Services.<br />

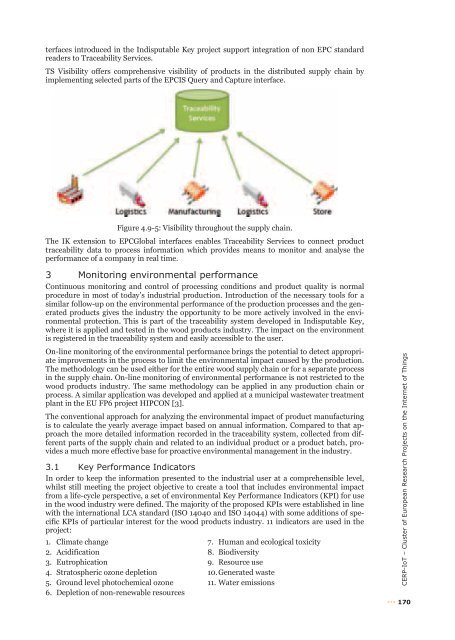

TS Visibility <strong>of</strong>fers comprehensive visibility <strong>of</strong> products in <strong>the</strong> distributed supply chain by<br />

implementing selected parts <strong>of</strong> <strong>the</strong> EPCIS Query <strong>and</strong> Capture interface.<br />

Figure 4.9-5: Visibility throughout <strong>the</strong> supply chain.<br />

The IK extension to EPCGlobal interfaces enables Traceability Services to connect product<br />

traceability data to process in<strong>for</strong>mation which provides means to monitor <strong>and</strong> analyse <strong>the</strong><br />

per<strong>for</strong>mance <strong>of</strong> a company in real time.<br />

3 Monitoring environmental per<strong>for</strong>mance<br />

Continuous monitoring <strong>and</strong> control <strong>of</strong> processing conditions <strong>and</strong> product quality is normal<br />

procedure in most <strong>of</strong> today’s industrial production. Introduction <strong>of</strong> <strong>the</strong> necessary tools <strong>for</strong> a<br />

similar follow-up on <strong>the</strong> environmental per<strong>for</strong>mance <strong>of</strong> <strong>the</strong> production processes <strong>and</strong> <strong>the</strong> generated<br />

products gives <strong>the</strong> industry <strong>the</strong> opportunity to be more actively involved in <strong>the</strong> environmental<br />

protection. This is part <strong>of</strong> <strong>the</strong> traceability system developed in Indisputable Key,<br />

where it is applied <strong>and</strong> tested in <strong>the</strong> wood products industry. The impact on <strong>the</strong> environment<br />

is registered in <strong>the</strong> traceability system <strong>and</strong> easily accessible to <strong>the</strong> user.<br />

On-line monitoring <strong>of</strong> <strong>the</strong> environmental per<strong>for</strong>mance brings <strong>the</strong> potential to detect appropriate<br />

improvements in <strong>the</strong> process to limit <strong>the</strong> environmental impact caused by <strong>the</strong> production.<br />

The methodology can be used ei<strong>the</strong>r <strong>for</strong> <strong>the</strong> entire wood supply chain or <strong>for</strong> a separate process<br />

in <strong>the</strong> supply chain. On-line monitoring <strong>of</strong> environmental per<strong>for</strong>mance is not restricted to <strong>the</strong><br />

wood products industry. The same methodology can be applied in any production chain or<br />

process. A similar application was developed <strong>and</strong> applied at a municipal wastewater treatment<br />

plant in <strong>the</strong> EU FP6 project HIPCON [3].<br />

The conventional approach <strong>for</strong> analyzing <strong>the</strong> environmental impact <strong>of</strong> product manufacturing<br />

is to calculate <strong>the</strong> yearly average impact based on annual in<strong>for</strong>mation. Compared to that approach<br />

<strong>the</strong> more detailed in<strong>for</strong>mation recorded in <strong>the</strong> traceability system, collected from different<br />

parts <strong>of</strong> <strong>the</strong> supply chain <strong>and</strong> related to an individual product or a product batch, provides<br />

a much more effective base <strong>for</strong> proactive environmental management in <strong>the</strong> industry.<br />

3.1 Key Per<strong>for</strong>mance Indicators<br />

In order to keep <strong>the</strong> in<strong>for</strong>mation presented to <strong>the</strong> industrial user at a comprehensible level,<br />

whilst still meeting <strong>the</strong> project objective to create a tool that includes environmental impact<br />

from a life-cycle perspective, a set <strong>of</strong> environmental Key Per<strong>for</strong>mance Indicators (KPI) <strong>for</strong> use<br />

in <strong>the</strong> wood industry were defined. The majority <strong>of</strong> <strong>the</strong> proposed KPIs were established in line<br />

with <strong>the</strong> international LCA st<strong>and</strong>ard (ISO 14040 <strong>and</strong> ISO 14044) with some additions <strong>of</strong> specific<br />

KPIs <strong>of</strong> particular interest <strong>for</strong> <strong>the</strong> wood products industry. 11 indicators are used in <strong>the</strong><br />

project:<br />

1. Climate change<br />

2. Acidification<br />

3. Eutrophication<br />

4. Stratospheric ozone depletion<br />

5. Ground level photochemical ozone<br />

6. Depletion <strong>of</strong> non-renewable resources<br />

7. Human <strong>and</strong> ecological toxicity<br />

8. Biodiversity<br />

9. Resource use<br />

10. Generated waste<br />

11. Water emissions<br />

CERP-IoT – Cluster <strong>of</strong> European Research Projects on <strong>the</strong> <strong>Internet</strong> <strong>of</strong> <strong>Things</strong><br />

170