Vision and Challenges for Realising the Internet of Things

Vision and Challenges for Realising the Internet of Things

Vision and Challenges for Realising the Internet of Things

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

An overview <strong>of</strong> <strong>the</strong> LCA procedure, creating <strong>the</strong> base <strong>for</strong> <strong>the</strong>se KPIs, is presented in <strong>the</strong> White<br />

Paper - How to gain from measuring environmental impact from wood products [4].<br />

The indicators are calculated <strong>and</strong> presented in Traceability Services (TS). The TS allows <strong>the</strong><br />

environmental impact from production <strong>of</strong> a product to be computed at item level, because<br />

in<strong>for</strong>mation regarding processes at each stage <strong>of</strong> production is tracked <strong>and</strong> used as input to<br />

<strong>the</strong> calculation <strong>of</strong> <strong>the</strong> KPIs. Typical in<strong>for</strong>mation which is needed in <strong>the</strong> KPI calculation is direct<br />

emissions to air (e.g. CO2 <strong>and</strong> particles), raw material use, resource consumption, energy<br />

use, generation <strong>of</strong> waste, production volumes <strong>and</strong> <strong>the</strong> ratio <strong>of</strong> different products. An initial<br />

inventory <strong>of</strong> <strong>the</strong> current situation is required <strong>for</strong> correct configuration <strong>of</strong> <strong>the</strong> KPIs in TS. When<br />

inputs are not measured on-line, <strong>and</strong> thus not available <strong>for</strong> automatic tracking in TS, results <strong>of</strong><br />

<strong>the</strong> inventory can be used as default values. The more detailed in<strong>for</strong>mation that is ga<strong>the</strong>red in<br />

TS from each stage <strong>of</strong> production <strong>the</strong> higher <strong>the</strong> specificity <strong>of</strong> <strong>the</strong> KPI <strong>and</strong> <strong>the</strong> higher <strong>the</strong> potential<br />

benefits <strong>for</strong> <strong>the</strong> users.<br />

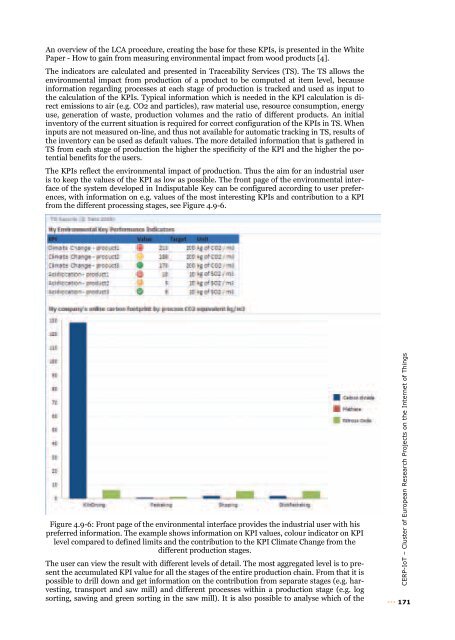

The KPIs reflect <strong>the</strong> environmental impact <strong>of</strong> production. Thus <strong>the</strong> aim <strong>for</strong> an industrial user<br />

is to keep <strong>the</strong> values <strong>of</strong> <strong>the</strong> KPI as low as possible. The front page <strong>of</strong> <strong>the</strong> environmental interface<br />

<strong>of</strong> <strong>the</strong> system developed in Indisputable Key can be configured according to user preferences,<br />

with in<strong>for</strong>mation on e.g. values <strong>of</strong> <strong>the</strong> most interesting KPIs <strong>and</strong> contribution to a KPI<br />

from <strong>the</strong> different processing stages, see Figure 4.9-6.<br />

Figure 4.9-6: Front page <strong>of</strong> <strong>the</strong> environmental interface provides <strong>the</strong> industrial user with his<br />

preferred in<strong>for</strong>mation. The example shows in<strong>for</strong>mation on KPI values, colour indicator on KPI<br />

level compared to defined limits <strong>and</strong> <strong>the</strong> contribution to <strong>the</strong> KPI Climate Change from <strong>the</strong><br />

different production stages.<br />

The user can view <strong>the</strong> result with different levels <strong>of</strong> detail. The most aggregated level is to present<br />

<strong>the</strong> accumulated KPI value <strong>for</strong> all <strong>the</strong> stages <strong>of</strong> <strong>the</strong> entire production chain. From that it is<br />

possible to drill down <strong>and</strong> get in<strong>for</strong>mation on <strong>the</strong> contribution from separate stages (e.g. harvesting,<br />

transport <strong>and</strong> saw mill) <strong>and</strong> different processes within a production stage (e.g. log<br />

sorting, sawing <strong>and</strong> green sorting in <strong>the</strong> saw mill). It is also possible to analyse which <strong>of</strong> <strong>the</strong><br />

CERP-IoT – Cluster <strong>of</strong> European Research Projects on <strong>the</strong> <strong>Internet</strong> <strong>of</strong> <strong>Things</strong><br />

171