Vision and Challenges for Realising the Internet of Things

Vision and Challenges for Realising the Internet of Things

Vision and Challenges for Realising the Internet of Things

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3.1 Au<strong>the</strong>ntication Features<br />

For each type <strong>of</strong> product, such as pharmaceuticals, plane spare parts, or luxury goods, appropriate<br />

tags that comply with <strong>the</strong> manufacturing processes have to be identified or developed.<br />

Different aspects <strong>of</strong> <strong>the</strong> product packaging <strong>and</strong> product materials need to be considered. A<br />

wide range <strong>of</strong> products from several vendors are available. A key challenge is <strong>the</strong> integration <strong>of</strong><br />

<strong>the</strong> tags into real life products. Factors to consider include cost, durability, reading speed,<br />

in<strong>for</strong>mation capacity, <strong>and</strong> <strong>of</strong> course security.<br />

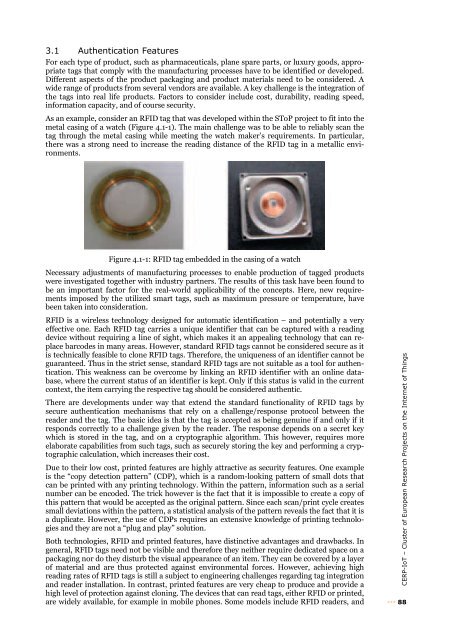

As an example, consider an RFID tag that was developed within <strong>the</strong> SToP project to fit into <strong>the</strong><br />

metal casing <strong>of</strong> a watch (Figure 4.1-1). The main challenge was to be able to reliably scan <strong>the</strong><br />

tag through <strong>the</strong> metal casing while meeting <strong>the</strong> watch maker’s requirements. In particular,<br />

<strong>the</strong>re was a strong need to increase <strong>the</strong> reading distance <strong>of</strong> <strong>the</strong> RFID tag in a metallic environments.<br />

Figure 4.1-1: RFID tag embedded in <strong>the</strong> casing <strong>of</strong> a watch<br />

Necessary adjustments <strong>of</strong> manufacturing processes to enable production <strong>of</strong> tagged products<br />

were investigated toge<strong>the</strong>r with industry partners. The results <strong>of</strong> this task have been found to<br />

be an important factor <strong>for</strong> <strong>the</strong> real-world applicability <strong>of</strong> <strong>the</strong> concepts. Here, new requirements<br />

imposed by <strong>the</strong> utilized smart tags, such as maximum pressure or temperature, have<br />

been taken into consideration.<br />

RFID is a wireless technology designed <strong>for</strong> automatic identification – <strong>and</strong> potentially a very<br />

effective one. Each RFID tag carries a unique identifier that can be captured with a reading<br />

device without requiring a line <strong>of</strong> sight, which makes it an appealing technology that can replace<br />

barcodes in many areas. However, st<strong>and</strong>ard RFID tags cannot be considered secure as it<br />

is technically feasible to clone RFID tags. There<strong>for</strong>e, <strong>the</strong> uniqueness <strong>of</strong> an identifier cannot be<br />

guaranteed. Thus in <strong>the</strong> strict sense, st<strong>and</strong>ard RFID tags are not suitable as a tool <strong>for</strong> au<strong>the</strong>ntication.<br />

This weakness can be overcome by linking an RFID identifier with an online database,<br />

where <strong>the</strong> current status <strong>of</strong> an identifier is kept. Only if this status is valid in <strong>the</strong> current<br />

context, <strong>the</strong> item carrying <strong>the</strong> respective tag should be considered au<strong>the</strong>ntic.<br />

There are developments under way that extend <strong>the</strong> st<strong>and</strong>ard functionality <strong>of</strong> RFID tags by<br />

secure au<strong>the</strong>ntication mechanisms that rely on a challenge/response protocol between <strong>the</strong><br />

reader <strong>and</strong> <strong>the</strong> tag. The basic idea is that <strong>the</strong> tag is accepted as being genuine if <strong>and</strong> only if it<br />

responds correctly to a challenge given by <strong>the</strong> reader. The response depends on a secret key<br />

which is stored in <strong>the</strong> tag, <strong>and</strong> on a cryptographic algorithm. This however, requires more<br />

elaborate capabilities from such tags, such as securely storing <strong>the</strong> key <strong>and</strong> per<strong>for</strong>ming a cryptographic<br />

calculation, which increases <strong>the</strong>ir cost.<br />

Due to <strong>the</strong>ir low cost, printed features are highly attractive as security features. One example<br />

is <strong>the</strong> “copy detection pattern” (CDP), which is a r<strong>and</strong>om-looking pattern <strong>of</strong> small dots that<br />

can be printed with any printing technology. Within <strong>the</strong> pattern, in<strong>for</strong>mation such as a serial<br />

number can be encoded. The trick however is <strong>the</strong> fact that it is impossible to create a copy <strong>of</strong><br />

this pattern that would be accepted as <strong>the</strong> original pattern. Since each scan/print cycle creates<br />

small deviations within <strong>the</strong> pattern, a statistical analysis <strong>of</strong> <strong>the</strong> pattern reveals <strong>the</strong> fact that it is<br />

a duplicate. However, <strong>the</strong> use <strong>of</strong> CDPs requires an extensive knowledge <strong>of</strong> printing technologies<br />

<strong>and</strong> <strong>the</strong>y are not a “plug <strong>and</strong> play” solution.<br />

Both technologies, RFID <strong>and</strong> printed features, have distinctive advantages <strong>and</strong> drawbacks. In<br />

general, RFID tags need not be visible <strong>and</strong> <strong>the</strong>re<strong>for</strong>e <strong>the</strong>y nei<strong>the</strong>r require dedicated space on a<br />

packaging nor do <strong>the</strong>y disturb <strong>the</strong> visual appearance <strong>of</strong> an item. They can be covered by a layer<br />

<strong>of</strong> material <strong>and</strong> are thus protected against environmental <strong>for</strong>ces. However, achieving high<br />

reading rates <strong>of</strong> RFID tags is still a subject to engineering challenges regarding tag integration<br />

<strong>and</strong> reader installation. In contrast, printed features are very cheap to produce <strong>and</strong> provide a<br />

high level <strong>of</strong> protection against cloning. The devices that can read tags, ei<strong>the</strong>r RFID or printed,<br />

are widely available, <strong>for</strong> example in mobile phones. Some models include RFID readers, <strong>and</strong><br />

CERP-IoT – Cluster <strong>of</strong> European Research Projects on <strong>the</strong> <strong>Internet</strong> <strong>of</strong> <strong>Things</strong><br />

88