Masoneilan Products SVI II ESD - GE Energy

Masoneilan Products SVI II ESD - GE Energy

Masoneilan Products SVI II ESD - GE Energy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Safety Information<br />

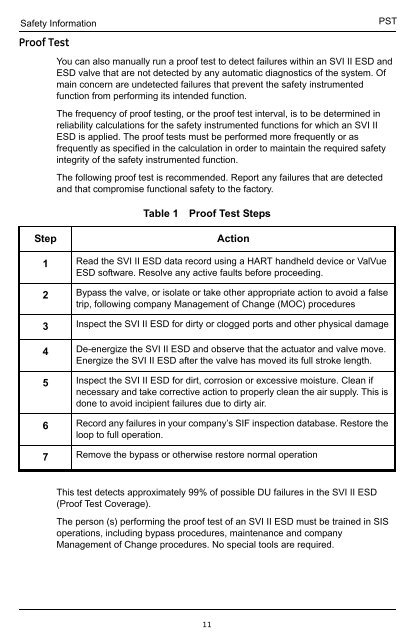

Proof Test<br />

You can also manually run a proof test to detect failures within an <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> and<br />

<strong>ESD</strong> valve that are not detected by any automatic diagnostics of the system. Of<br />

main concern are undetected failures that prevent the safety instrumented<br />

function from performing its intended function.<br />

The frequency of proof testing, or the proof test interval, is to be determined in<br />

reliability calculations for the safety instrumented functions for which an <strong>SVI</strong> <strong>II</strong><br />

<strong>ESD</strong> is applied. The proof tests must be performed more frequently or as<br />

frequently as specified in the calculation in order to maintain the required safety<br />

integrity of the safety instrumented function.<br />

The following proof test is recommended. Report any failures that are detected<br />

and that compromise functional safety to the factory.<br />

Table 1 Proof Test Steps<br />

PST<br />

Step<br />

Action<br />

1 Read the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> data record using a HART handheld device or ValVue<br />

<strong>ESD</strong> software. Resolve any active faults before proceeding.<br />

2 Bypass the valve, or isolate or take other appropriate action to avoid a false<br />

trip, following company Management of Change (MOC) procedures<br />

3 Inspect the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> for dirty or clogged ports and other physical damage<br />

4 De-energize the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> and observe that the actuator and valve move.<br />

Energize the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> after the valve has moved its full stroke length.<br />

5 Inspect the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> for dirt, corrosion or excessive moisture. Clean if<br />

necessary and take corrective action to properly clean the air supply. This is<br />

done to avoid incipient failures due to dirty air.<br />

6 Record any failures in your company’s SIF inspection database. Restore the<br />

loop to full operation.<br />

7 Remove the bypass or otherwise restore normal operation<br />

This test detects approximately 99% of possible DU failures in the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong><br />

(Proof Test Coverage).<br />

The person (s) performing the proof test of an <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> must be trained in SIS<br />

operations, including bypass procedures, maintenance and company<br />

Management of Change procedures. No special tools are required.<br />

11