Masoneilan Products SVI II ESD - GE Energy

Masoneilan Products SVI II ESD - GE Energy

Masoneilan Products SVI II ESD - GE Energy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Installation and<br />

Mounting the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> on Rotary Valves<br />

Mounting the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> on<br />

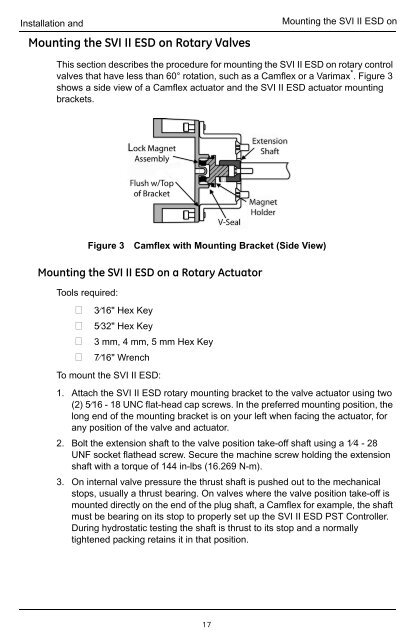

This section describes the procedure for mounting the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> on rotary control<br />

valves that have less than 60° rotation, such as a Camflex or a Varimax * . Figure 3<br />

shows a side view of a Camflex actuator and the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> actuator mounting<br />

brackets.<br />

Figure 3 Camflex with Mounting Bracket (Side View)<br />

Mounting the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> on a Rotary Actuator<br />

Tools required:<br />

3⁄16" Hex Key<br />

5⁄32" Hex Key<br />

3 mm, 4 mm, 5 mm Hex Key<br />

7⁄16" Wrench<br />

To mount the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong>:<br />

1. Attach the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> rotary mounting bracket to the valve actuator using two<br />

(2) 5⁄16 - 18 UNC flat-head cap screws. In the preferred mounting position, the<br />

long end of the mounting bracket is on your left when facing the actuator, for<br />

any position of the valve and actuator.<br />

2. Bolt the extension shaft to the valve position take-off shaft using a 1⁄4 - 28<br />

UNF socket flathead screw. Secure the machine screw holding the extension<br />

shaft with a torque of 144 in-lbs (16.269 N-m).<br />

3. On internal valve pressure the thrust shaft is pushed out to the mechanical<br />

stops, usually a thrust bearing. On valves where the valve position take-off is<br />

mounted directly on the end of the plug shaft, a Camflex for example, the shaft<br />

must be bearing on its stop to properly set up the <strong>SVI</strong> <strong>II</strong> <strong>ESD</strong> PST Controller.<br />

During hydrostatic testing the shaft is thrust to its stop and a normally<br />

tightened packing retains it in that position.<br />

17